Temperature, humidity and wind speed integrated sensing system of fiber grating

A fiber grating and sensing system technology, applied in the direction of physical/chemical change thermometer, thermometer, speed/acceleration/shock measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The fiber grating temperature, humidity and wind speed integrated composite sensing system of the present invention will be described in detail below in conjunction with the accompanying drawings. These descriptions are only exemplary and are not intended to limit the present invention.

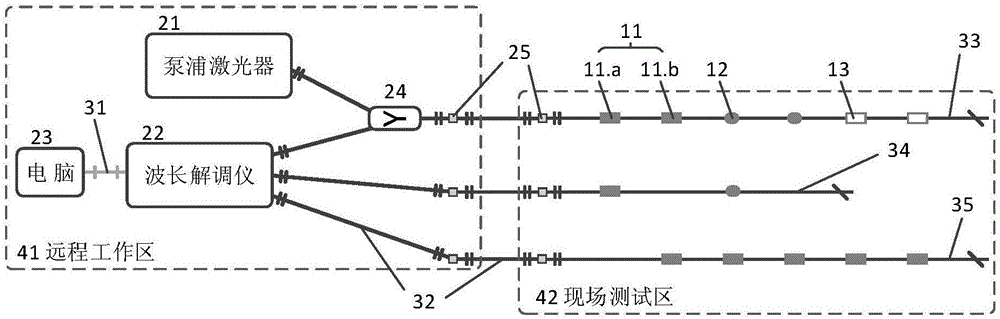

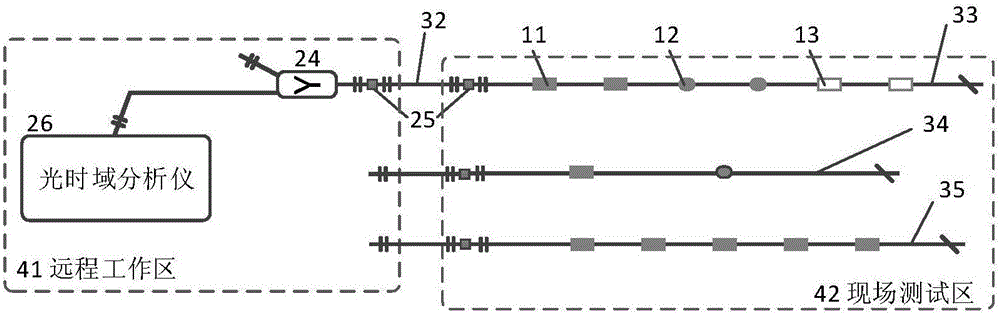

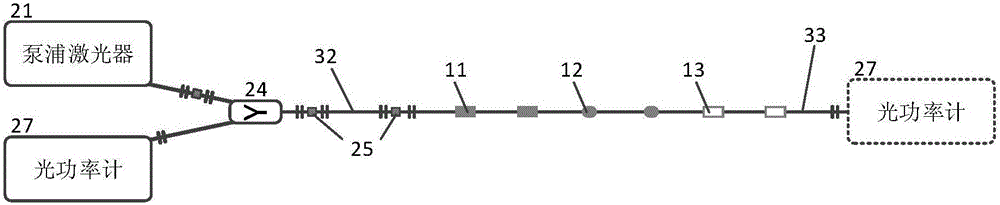

[0021] figure 1 The structure of the fiber grating temperature, humidity and wind speed integrated composite sensing system of the present invention is shown, wherein the system of the present invention includes a pump laser 21, a wavelength demodulator 22, a computer terminal 23, a wavelength division coupler 24, A test optical fiber one 33, a test optical fiber two 34 and a temperature reference optical fiber 35 in the test environment connected by the optical fiber connector 25, the control line 31, and the jumper optical fiber 32, the three optical fibers include at least 13 test points, respectively measured to obtain the on-site Multi-point temperature, humidity and wind speed pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com