a combined combustion chamber

A combustion chamber and pre-combustion stage technology, which is applied in the field of combustion chamber to achieve high-efficiency and low-emission combustion, widen the flame stability range, and strengthen the effect of blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the drawings and specific implementations.

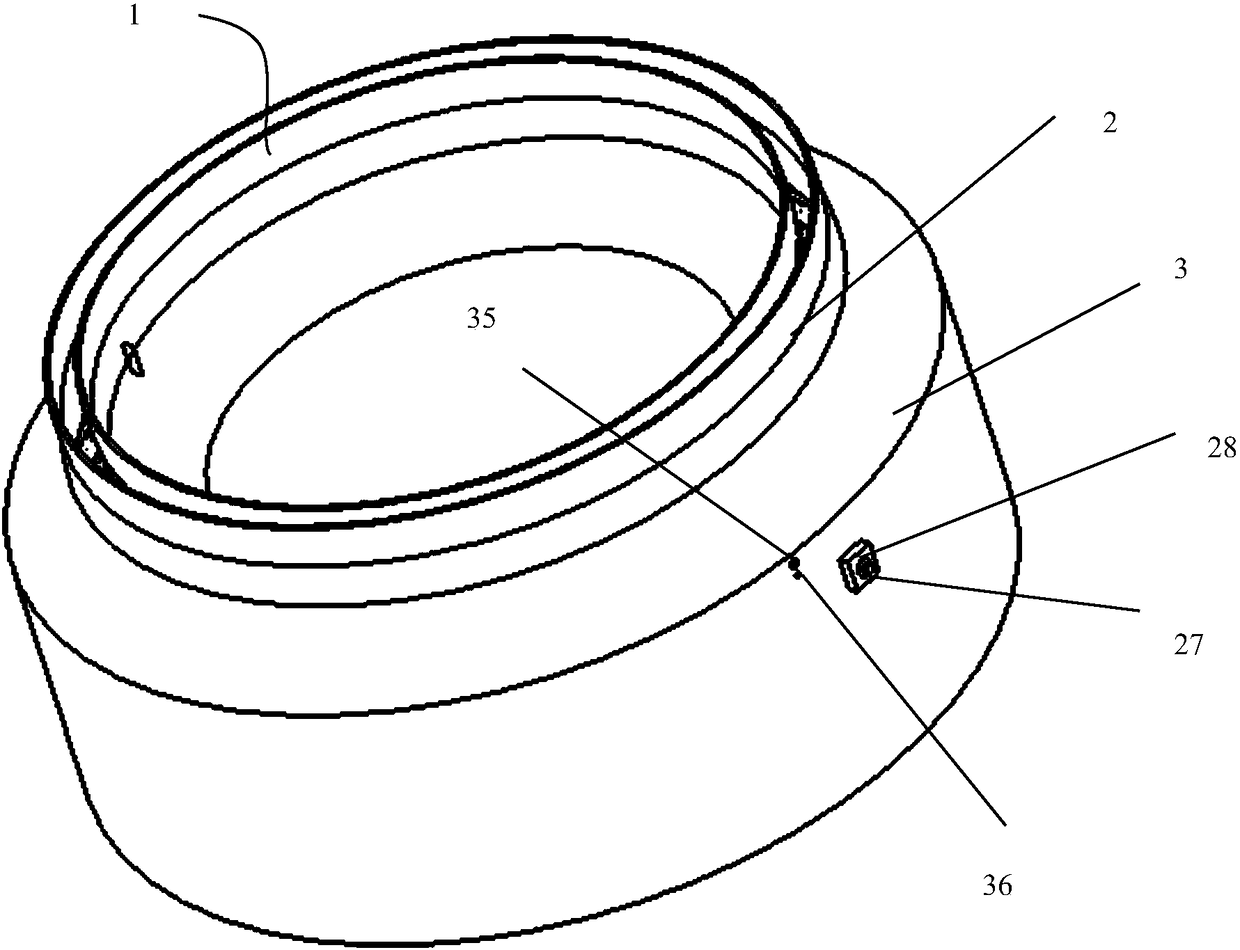

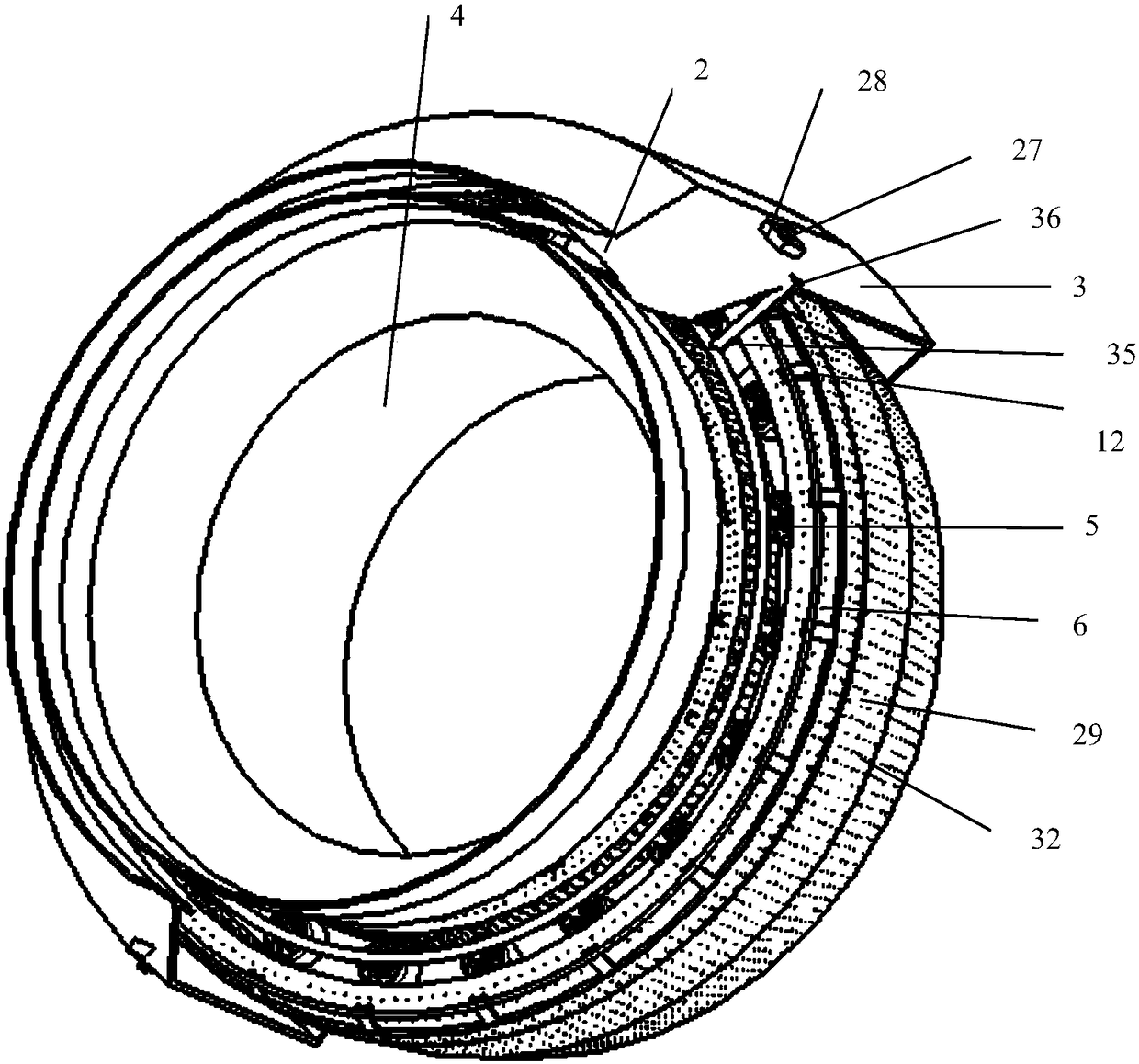

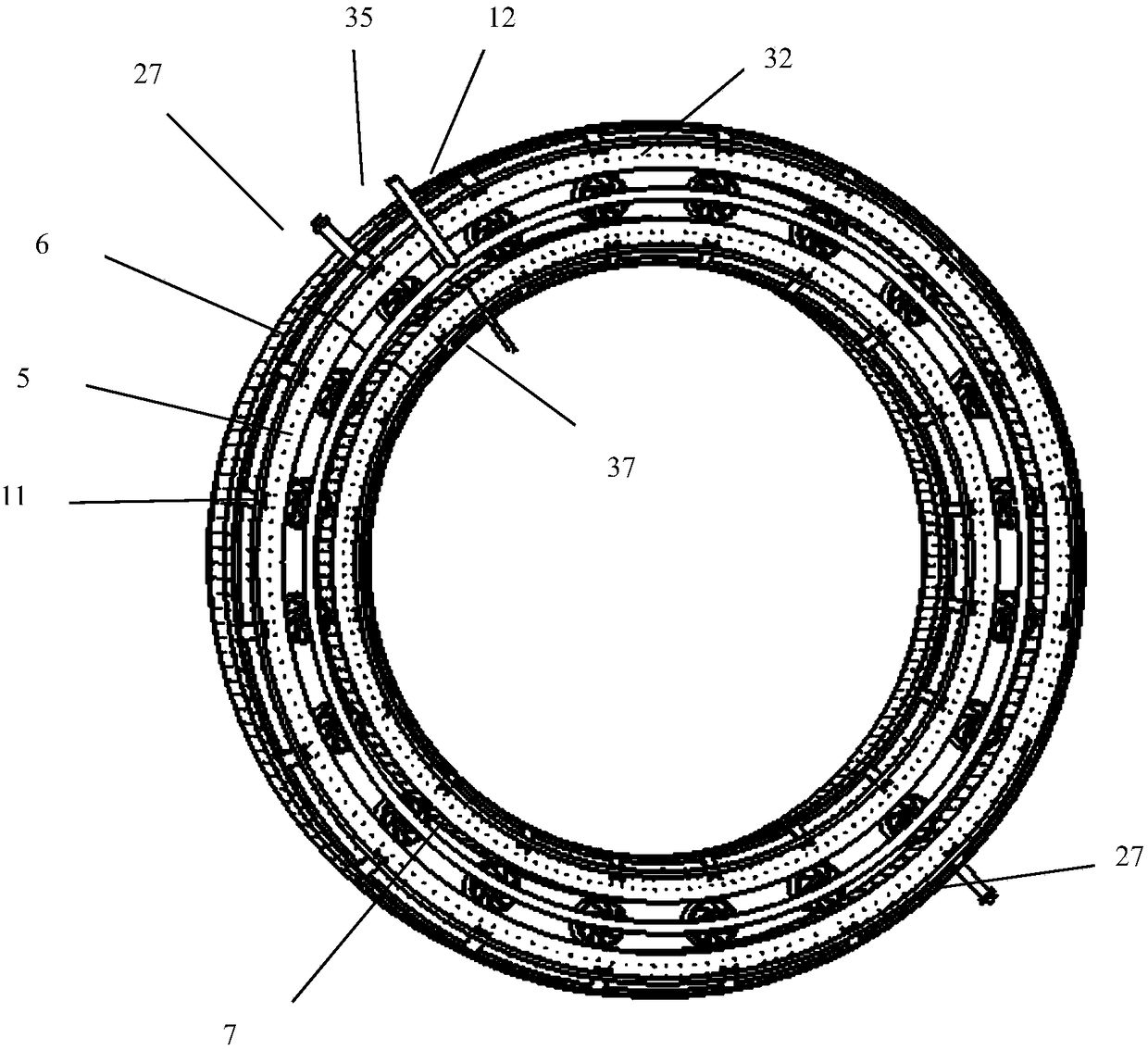

[0034] Please refer to Figure 1 to Figure 5 As shown, the combined combustion chamber of the present invention is mainly composed of a diffuser 2, a combustion outdoor casing 3 and an inner casing 4, a flame tube 29 with a double cavity structure on the head, a high-energy ignition nozzle 27, a swirler 11, etc. composition. The combined combustion chamber has a full annular structure, and the pre-combustion stage outer cavity 16 and the pre-combustion stage inner cavity 17 formed by a special structural design are used to form the pre-combustion stage outer cavity recirculation zone 22 and the pre-combustion stage inner cavity The recirculation zone 23 stabilizes the flame, and the flame is transmitted from the outer cavity 16 to the inner cavity 17 and the main flow by relying on the cross-fire plate 26 formed by the flame tube between the two cavities....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com