1000mw ultra supercritical double reheat boiler with high reheat steam temperature and wide adjustment ratio

A technology of secondary reheating and reheating steam, which is used in the control of superheated temperature, steam superheating, steam generation, etc., can solve the problem of increasing investment costs and operating costs, cannot improve secondary reheating requirements, and affects the stability of combustion in the furnace. and other problems, to achieve the effect of reducing the heat loss of exhaust smoke, ensuring economy and safety, and avoiding uneven heat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The 1000MW ultra-supercritical double reheating boiler of the present invention will be further described below.

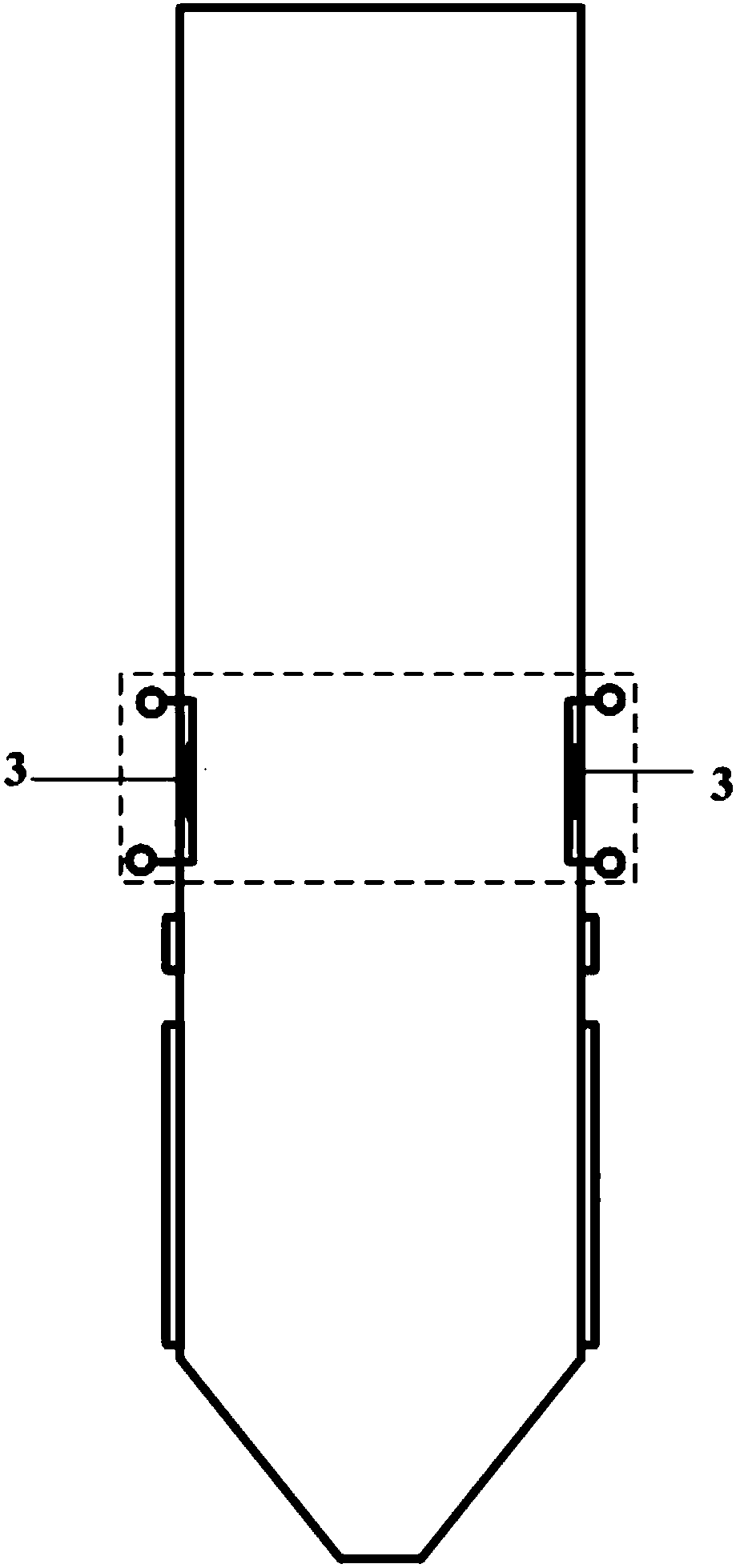

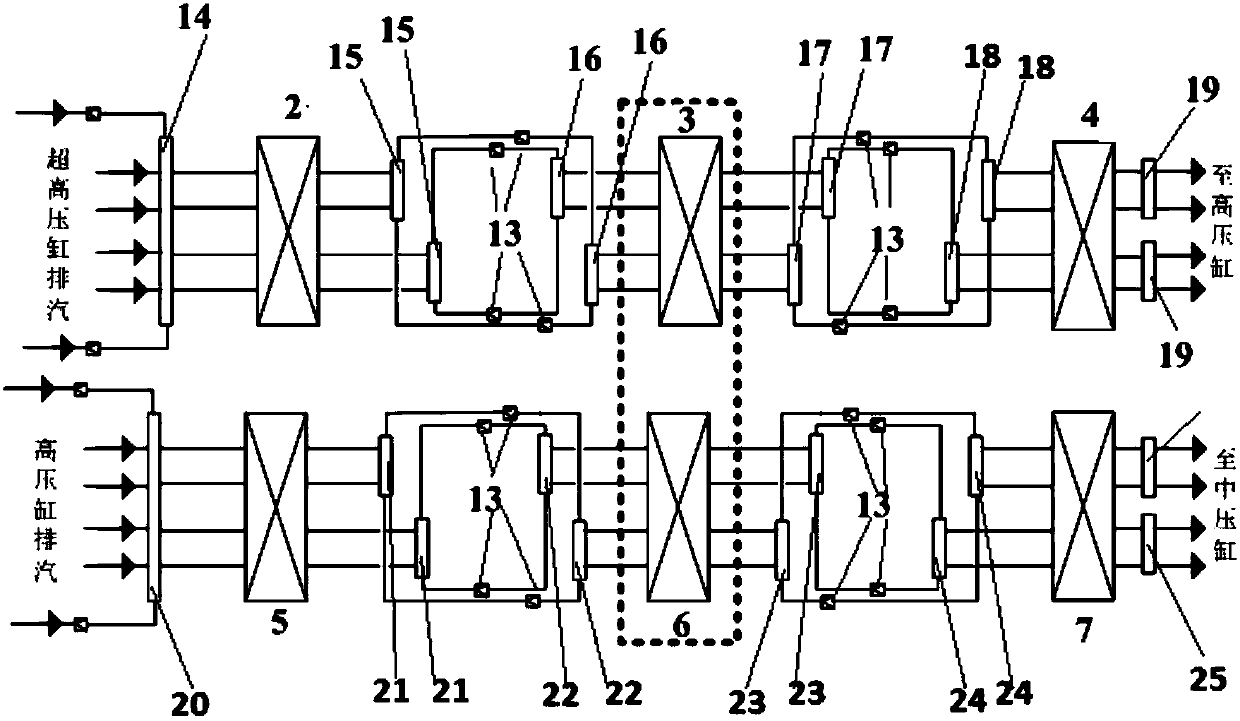

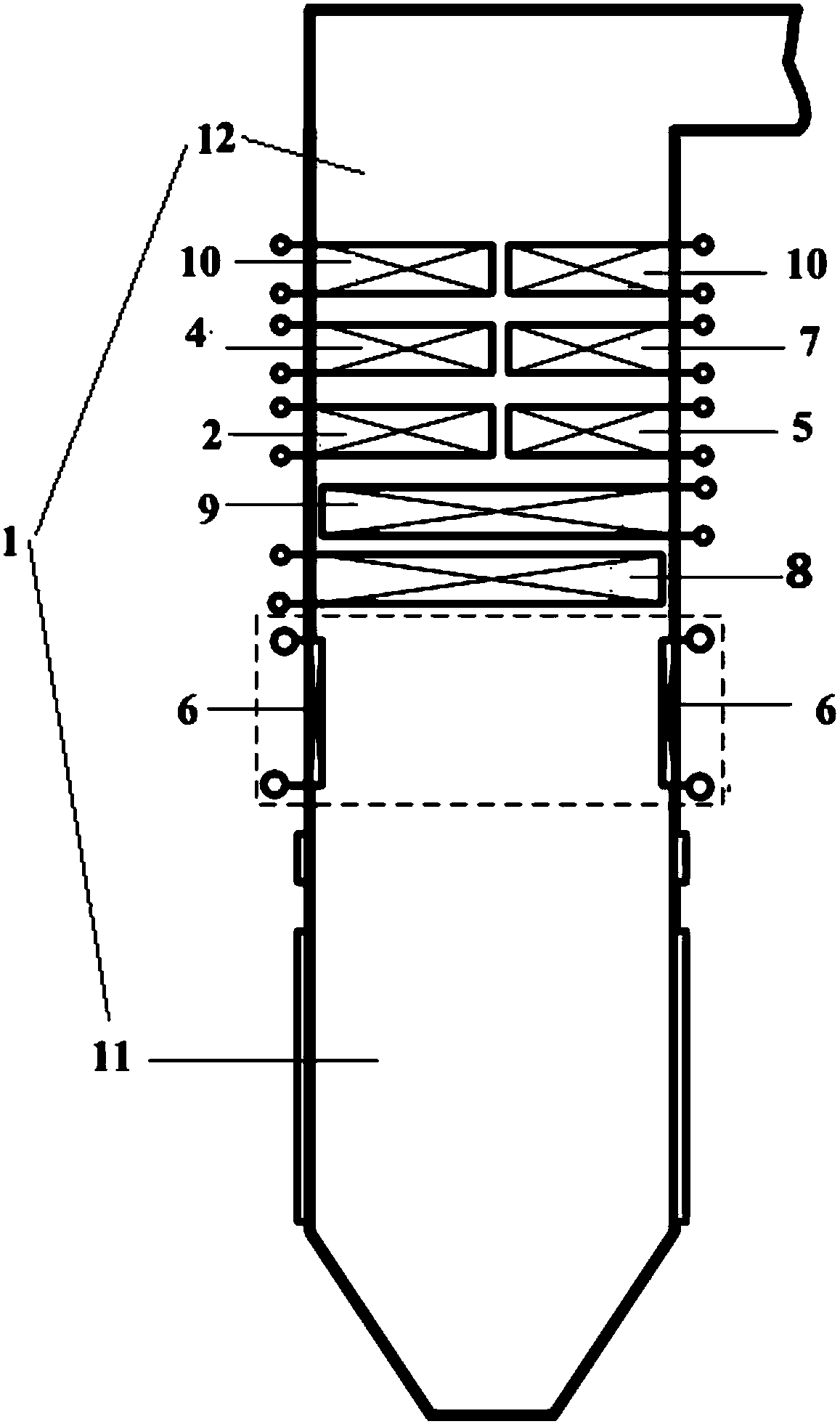

[0021] 1000MW ultra supercritical double reheat boiler with high reheat steam temperature and wide adjustment ratio, see figure 1 and 2 , including the boiler body 1, the primary reheat low-temperature reheater 2, the primary reheat wall reheater 3, the primary reheat high-temperature reheater 4 connected in sequence, and the secondary reheat low-temperature reheater 5 connected in sequence , secondary reheating wall reheater 6, secondary reheating high temperature reheater 7; the boiler body 1 includes a furnace 11 and an outlet flue 12; the vertical water-cooled wall sections in the furnace 11 are symmetrically arranged on the front and rear walls Wall reheater 3, secondary reheating wall reheater 6 is symmetrically arranged on the left and right walls of the vertical water-cooled wall section in the furnace 11; the outlet flue 12 is provided with low-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com