Milling and plowing head adjusting rack for tunnel underground excavation machine

A technology of milling head and underground excavator, used in tunnels, mining equipment, earth-moving drilling and other directions, can solve the problems of low excavation efficiency and inconvenient platform excavation, and achieve the effects of fast excavation, simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the present invention clearer, the device will be described in detail below with reference to the accompanying drawings. The specific embodiments described herein are only used to explain the present invention, and are not intended to limit the present invention.

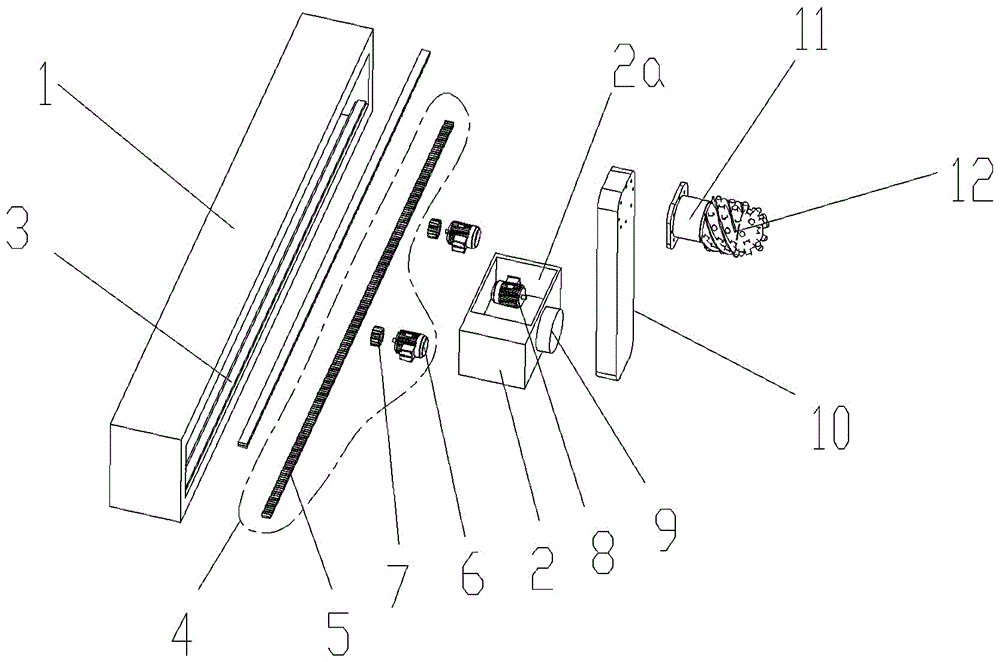

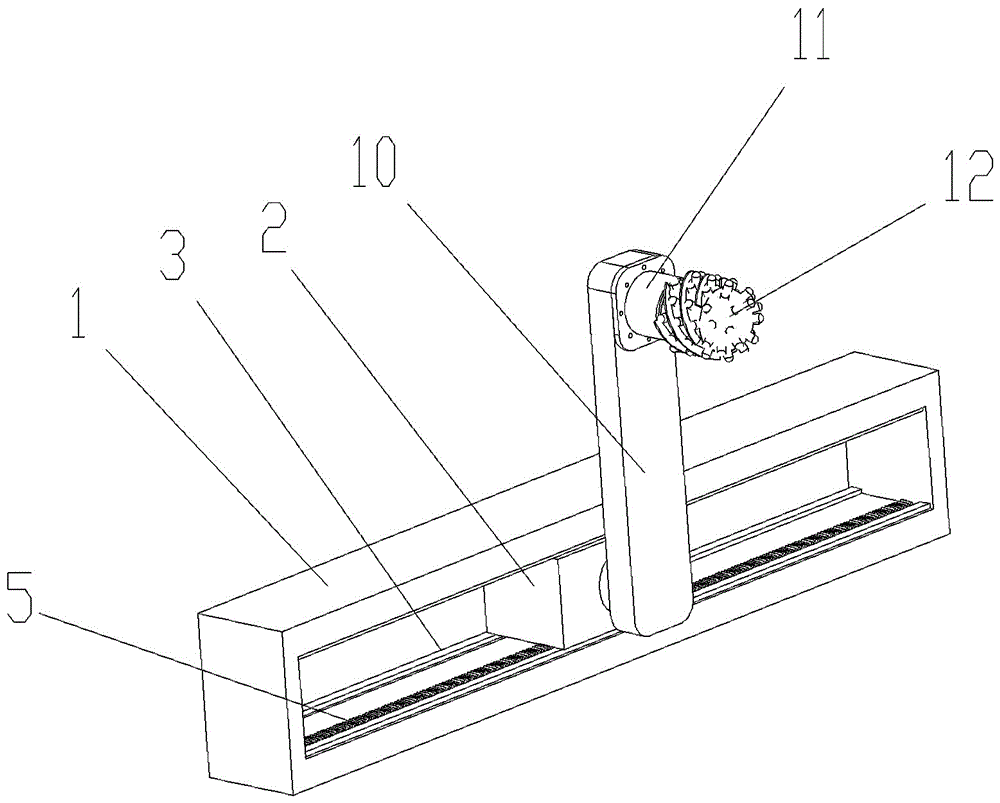

[0018] like figure 1 and figure 2 As shown, the present invention provides a milling head adjusting frame for a tunnel excavator, comprising a cutter head frame 1 which is a cuboid annular plate, and two mutually parallel guide rails 3 are connected in the cutter head frame 1, At least one adjustment box 2 is connected between the two guide rails 3 , and each adjustment box 2 is driven to move on the guide rail 3 by two transverse transmission devices 4 , the adjustment box 2 is a square box structure, in its Both the upper side and the lower side are provided with a cavity 2a. The transverse transmission device 4 includes a rack 5 which is transversely connected in the cutter head frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com