A chemical agent-assisted CO2 huff and puff method to improve the recovery of ordinary heavy oil reservoirs

A technology for heavy oil reservoirs and chemical agents, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc. It can solve the problems of periodic oil production, decrease in oil-gas ratio, large difference in oil-gas flow rate, and small sweep volume, etc. problems, to achieve the effect of reducing the flow resistance of crude oil, reducing the viscosity of crude oil, and reducing the flow resistance of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

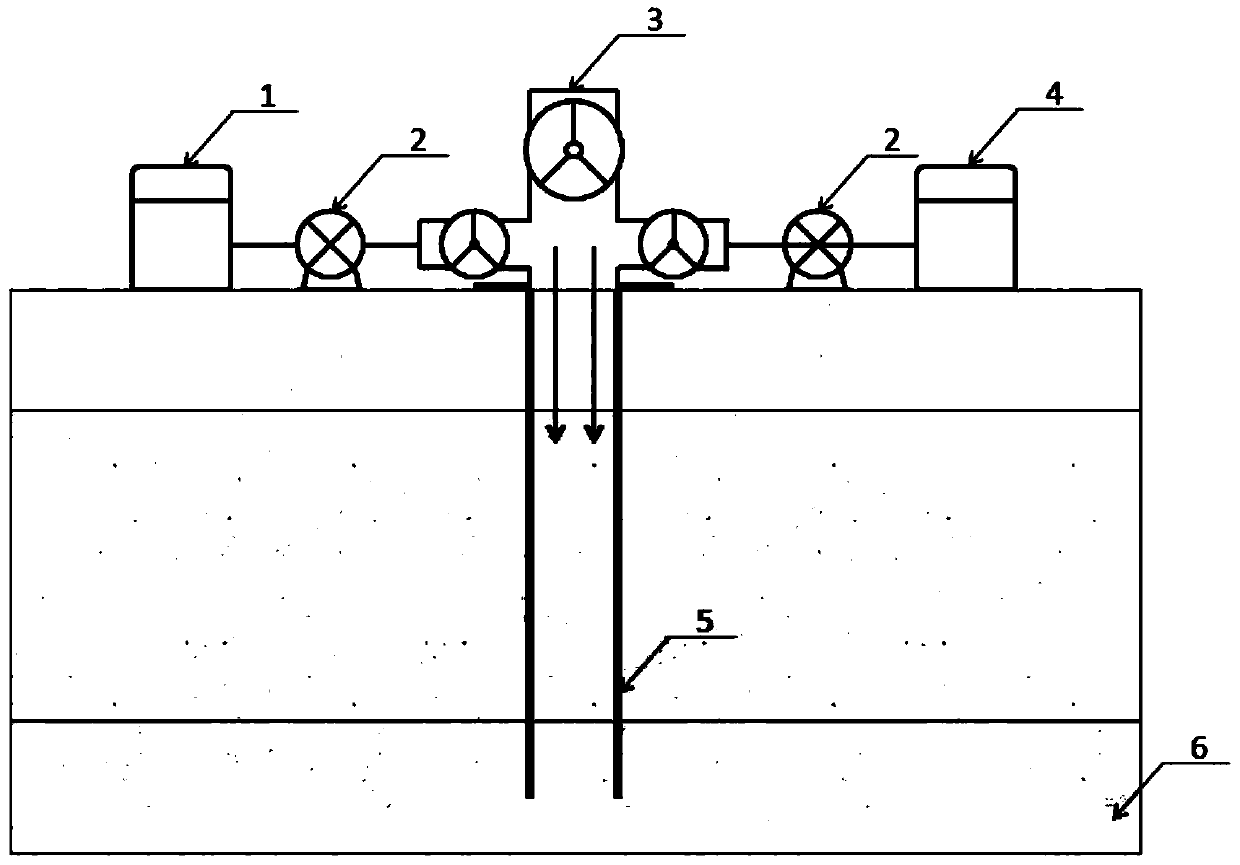

[0033] A chemical agent assists CO 2 The method of huff and puff to improve the recovery of ordinary heavy oil reservoirs, the process is as follows figure 1 As shown, the high pressure CO is passed through the pressure pipeline 2 The outlet of the storage tank 1 is connected to the ground injection device 2, and the ground injection device 2 and the injection well 3 are connected through a pipeline. The foaming agent aqueous solution storage tank 4 is connected to the ground injection device 2 through a pipeline, and the ground injection device 2 and the injection well are connected through a pipeline. 3.

[0034] The specific steps are as follows:

[0035] (1) Foaming agent solution slug injection process: Di-(2-ethylhexyl)-sodium sulfosuccinate foaming agent is formulated into foaming agent aqueous solution, injected into the formation from the wellbore, the mass concentration of foaming agent aqueous solution is 0.5%, the volume injected into the foaming agent aqueous s...

Embodiment 2

[0041] A chemical agent assists CO 2 The method for improving the recovery factor of ordinary heavy oil reservoirs by huffing and puffing includes the following steps:

[0042] (1) The slug injection process of the viscosity reducer solution: the alkyl sulfonate viscosity reducer is prepared into a viscosity reducer aqueous solution, which is injected into the formation from the wellbore. The mass concentration of the viscosity reducer aqueous solution is 1.0%, and the viscosity reducer aqueous solution is injected has a volume of 12m 3 ;

[0043] (2) High pressure CO 2 Slug injection process: the CO 2 The slug is pressurized by ground pressurization equipment, injected into the reservoir from the wellbore, and CO 2 The volume ratio of the volume of the injected chemical agent aqueous solution is 1:1;

[0044] (3) Stew well diffusion: CO 2 After injection into the oil layer, the well was shut down and blotted for 10 days, and the pressure changes during the brine process...

Embodiment 3

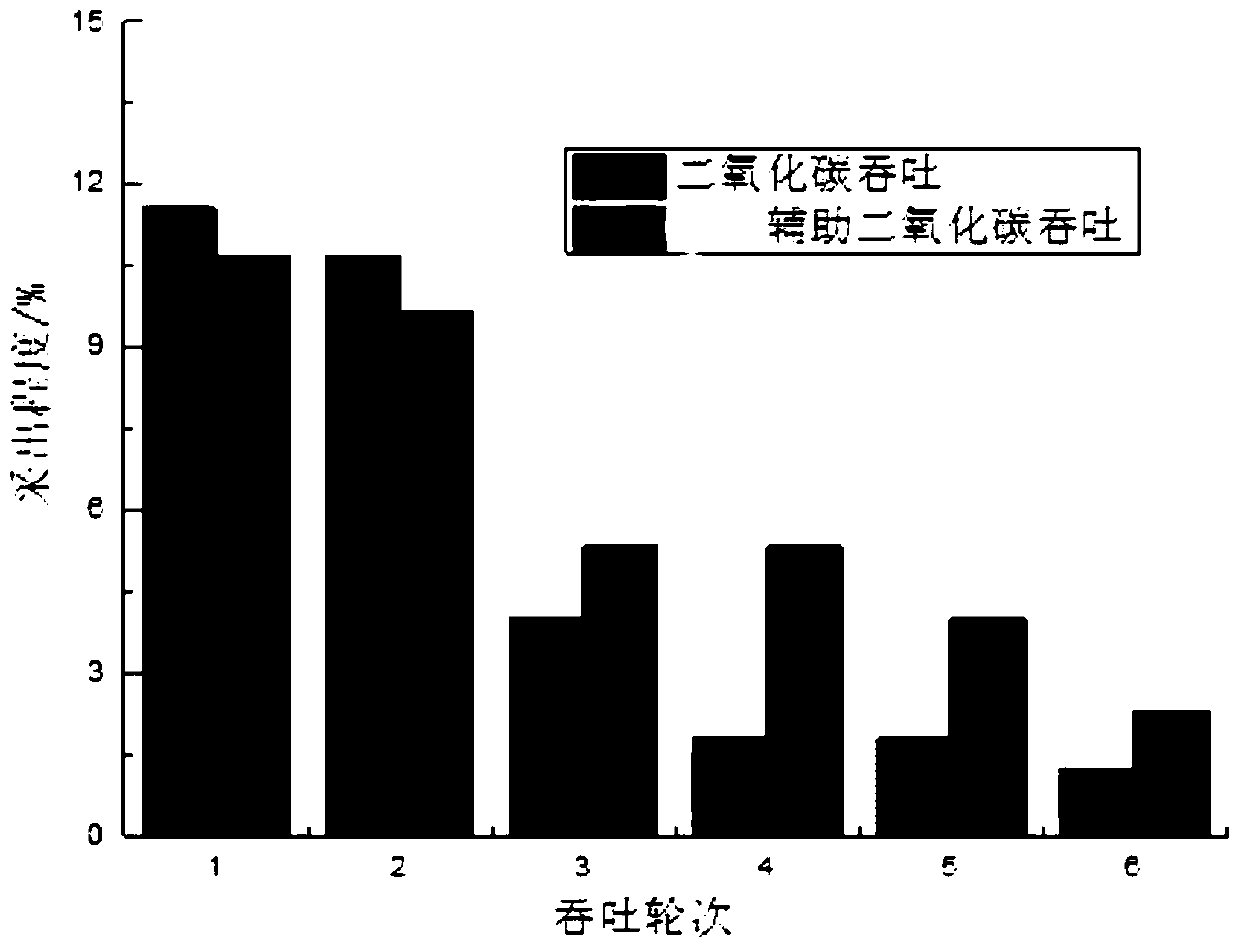

[0048] Simulated chemical agent assisted CO 2 The experimental equipment for huff and puff exploitation of ordinary heavy oil reservoirs is mainly composed of double-plunger metering pumps for liquid displacement, double-plunger metering pumps for gas displacement, pressure transmitters, balances, sand filling pipes, temperature and pressure control and recording systems, etc. Composition, the experiment was carried out under constant temperature and pressure to simulate the reservoir environment.

[0049] The specific steps are:

[0050] (1) Fill a rock core with a certain permeability using a sand filling pipe, weigh the dry weight, vacuumize, saturate with water, weigh the wet weight, calculate the porosity, and measure the water phase permeability of the rock core;

[0051] (2) Adjust the core to a formation temperature of 60°C and a formation pressure;

[0052] (3) Saturate the oil at a speed of 0.5ml / min until the output liquid at the outlet end is free of water, close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com