Self-repairing super-hydrophobic composite material, preparation method and application thereof

A composite material and super-hydrophobic technology, applied in the field of super-hydrophobic composite materials, can solve the problems of no self-repair, local sharp convex structures are easily damaged, and it is difficult to maintain mechanical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of Nanosilver

[0034] Dissolve 45 mg of hydrolyzed casein and 10 mg of sodium hydroxide in 45 mL of deionized water, then drop into 5 mL of silver nitrate (20 mM) solution. The above mixed solution was heated with magnetic stirring at 60 °C for 3 h, mixed with alcohol 1:4 and centrifuged at 20000 × g at high speed, and finally the precipitate was washed with deionized water and dried in vacuum to obtain silver nanoparticles (Ag NPs) particles.

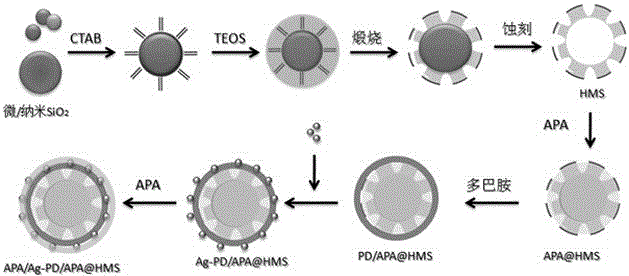

[0035] 2. Preparation of nanoscale hollow mesoporous silica (HMS)

[0036] First, in 1 L of deionized water, add 5 g of purchased nanoscale (200 nm–500 nm) spherical monodisperse solid SiO 2 Microspheres, and ultrasonically dispersed to form white SiO 2 Emulsion; then mix CTAB, ethanol and deionized water in a volume ratio of 5:1:1, and adjust the pH value of the solution to 8.0~8.5 with ammonia water; mix the solution with the above SiO 2 The emulsion is mixed according to the volume ratio of 10:1. After unifor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com