A method for separating potassium chloride in flotation froth and a dissolution kettle

A technology for dissolving kettles and potassium chloride, applied in the direction of alkali metal chlorides, etc., can solve the problems of long process flow and high cost, and achieve the effect of simple and efficient operation, low cost and low cost recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

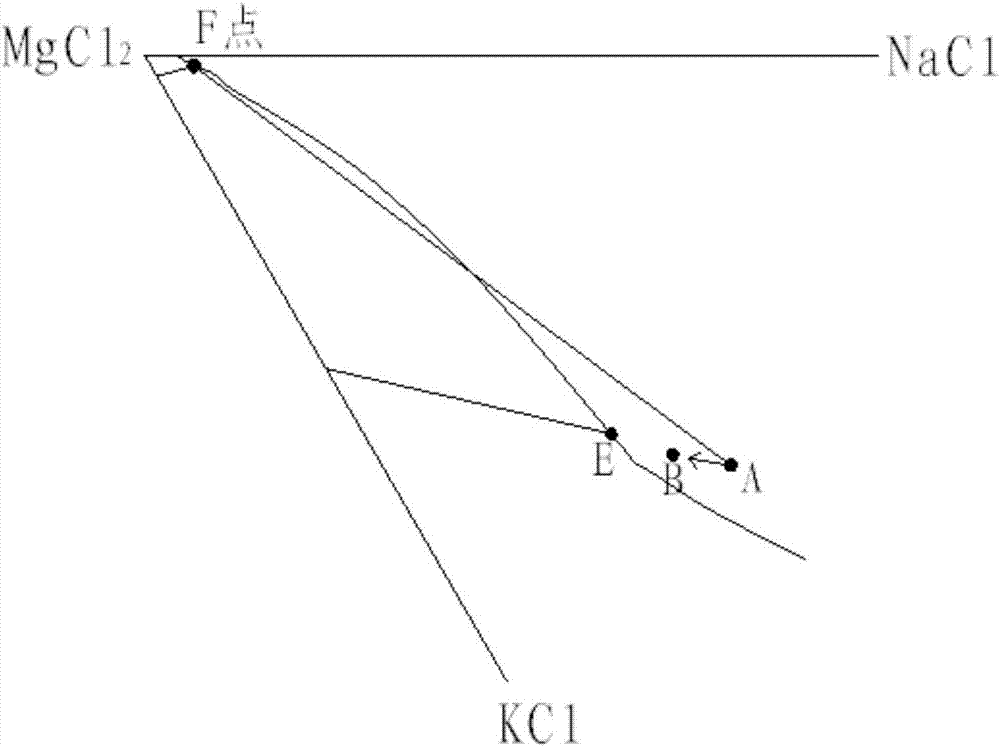

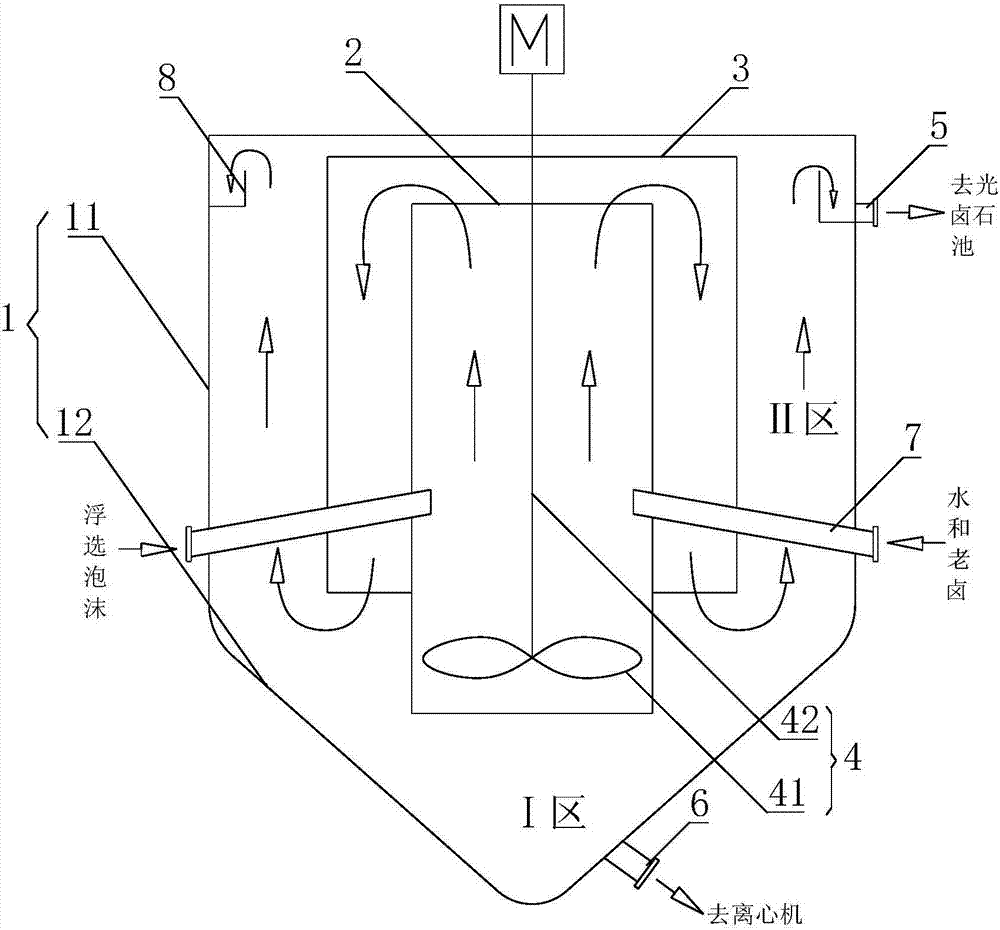

[0043] Such as figure 1 As shown, the present embodiment provides a method for separating potassium chloride in the flotation froth, and proceeds according to the following steps:

[0044]Step 1: Using the original carnallite (that is, the carnallite collected from the salt lake) as the raw material, the flotation foam is obtained by the reverse flotation method: specifically, the flotation agent is added to the original carnallite to make the original carnallite The surface of sodium chloride in the stone generates hydrophobicity, so that the bubbles float to the surface of the slurry to form flotation foam. The output of the flotation froth obtained in the process of this embodiment is 40 tons / hour.

[0045] Take a sample to obtain the potassium chloride mass m contained in every 100g solid dry basis contained in the flotation foam 1 : Take out a small amount of flotation foam, realize solid-liquid separation to it, extract the solid phase therein, divide the solid phase i...

Embodiment 2

[0071] Such as figure 1 As shown, the present embodiment provides a method for separating potassium chloride in the flotation froth, and proceeds according to the following steps:

[0072] Step 1: Using the original carnallite (that is, the carnallite collected from the salt lake) as the raw material, the flotation foam is obtained by the reverse flotation method: specifically, the flotation agent is added to the original carnallite to make the original carnallite The surface of sodium chloride in the stone generates hydrophobicity, so that the bubbles float to the surface of the slurry to form flotation foam. The output of the flotation froth obtained in the process of this embodiment is 50 tons / hour.

[0073] Take a sample to obtain the potassium chloride content m contained in every 100g solid dry basis contained in the flotation foam 2 : Take out a small amount of flotation foam, realize solid-liquid separation to it, extract the solid phase therein, divide the solid phase...

Embodiment 3

[0081] Such as figure 1 As shown, the present embodiment provides a method for separating potassium chloride in the flotation froth, and proceeds according to the following steps:

[0082] Step 1: Using the original carnallite (that is, the carnallite collected from the salt lake) as the raw material, the flotation foam is obtained by the reverse flotation method: specifically, the flotation agent is added to the original carnallite to make the original carnallite The surface of sodium chloride in the stone generates hydrophobicity, so that the bubbles float to the surface of the slurry to form flotation foam. The output of the flotation froth obtained in the process of this embodiment is 30 tons / hour.

[0083] Take a sample to obtain the potassium chloride content m contained in every 100g solid dry basis contained in the flotation foam 3 : Take out a small amount of flotation foam, realize solid-liquid separation to it, extract the solid phase therein, divide the solid pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com