Automatic Glass Cutting Instrument

A glass and automatic technology, applied in the field of medical equipment, can solve the problems of damage, liquid pollution, bleeding, etc., and achieve the effect of easy operation of the instrument, avoiding drug pollution, and great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

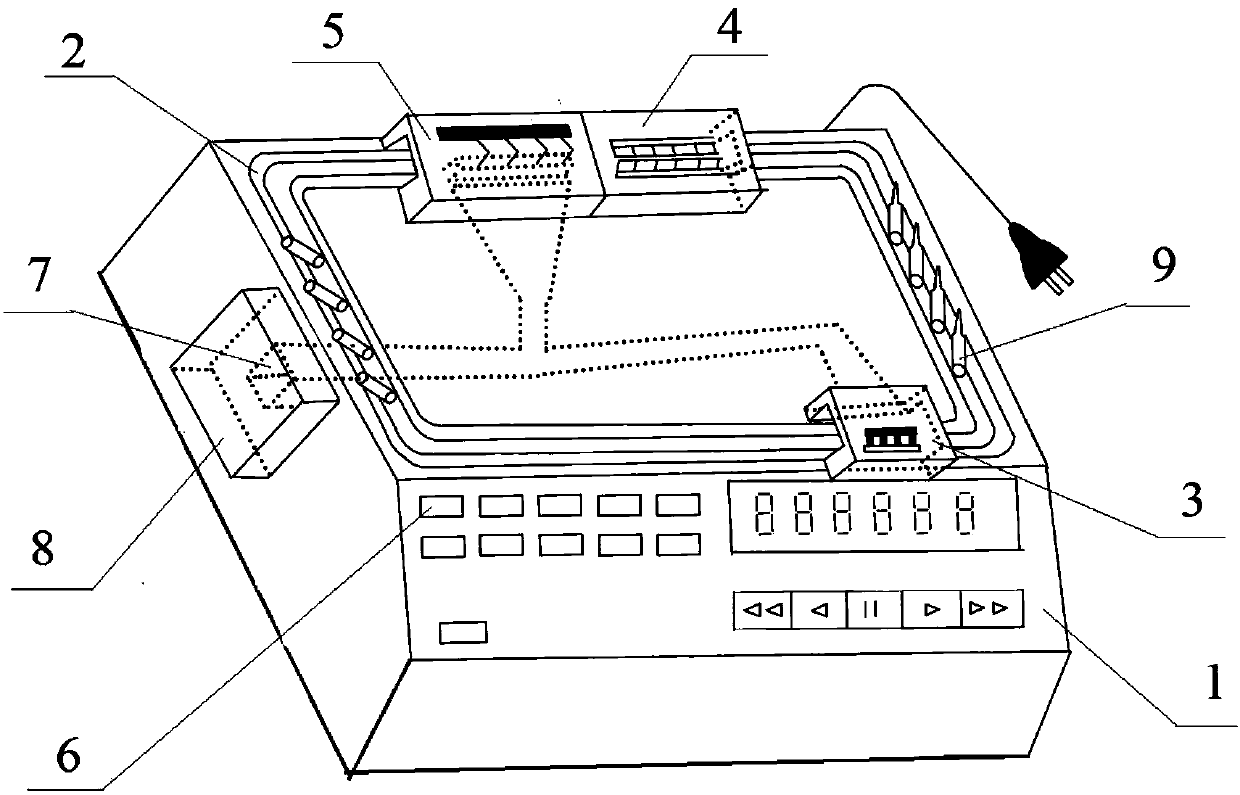

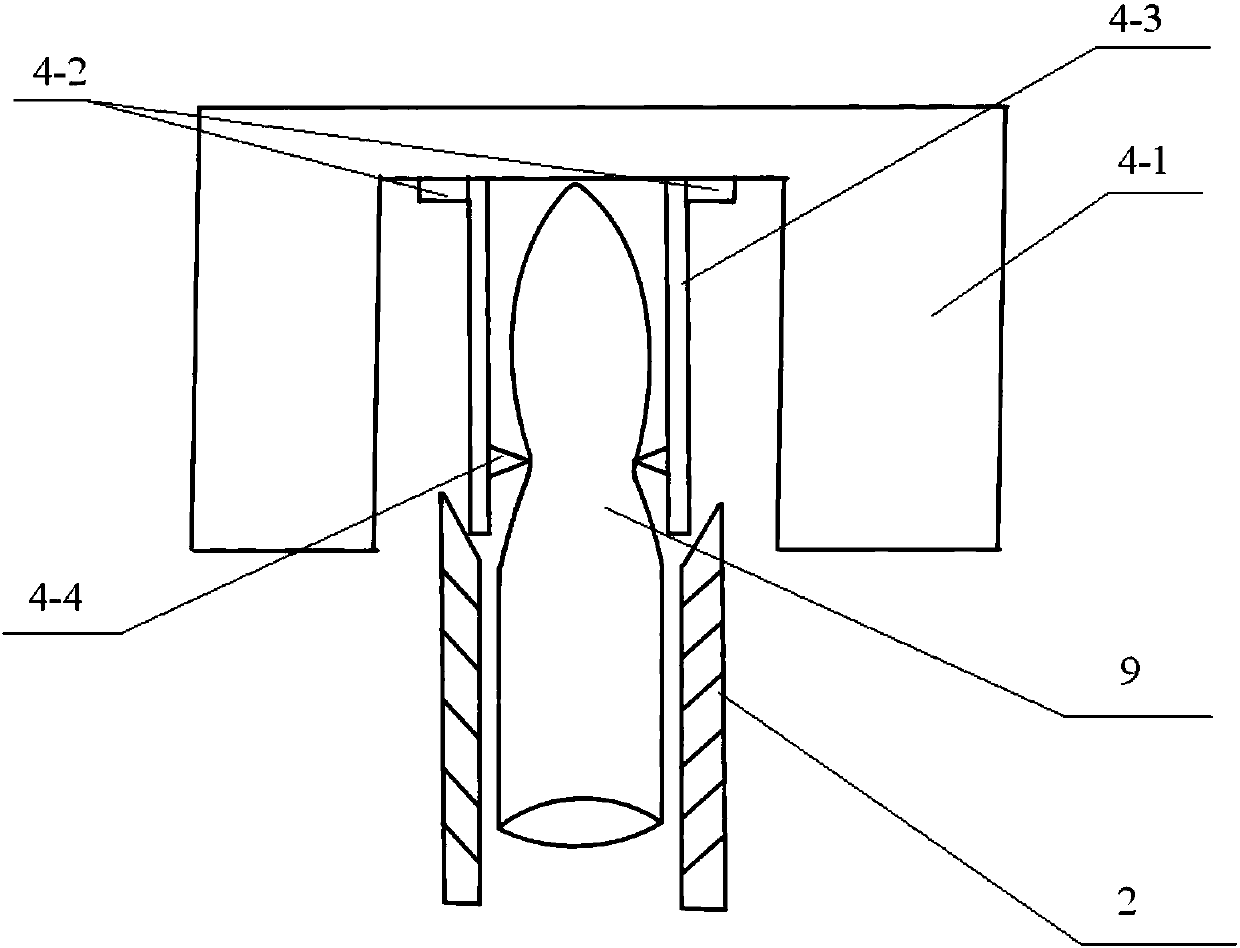

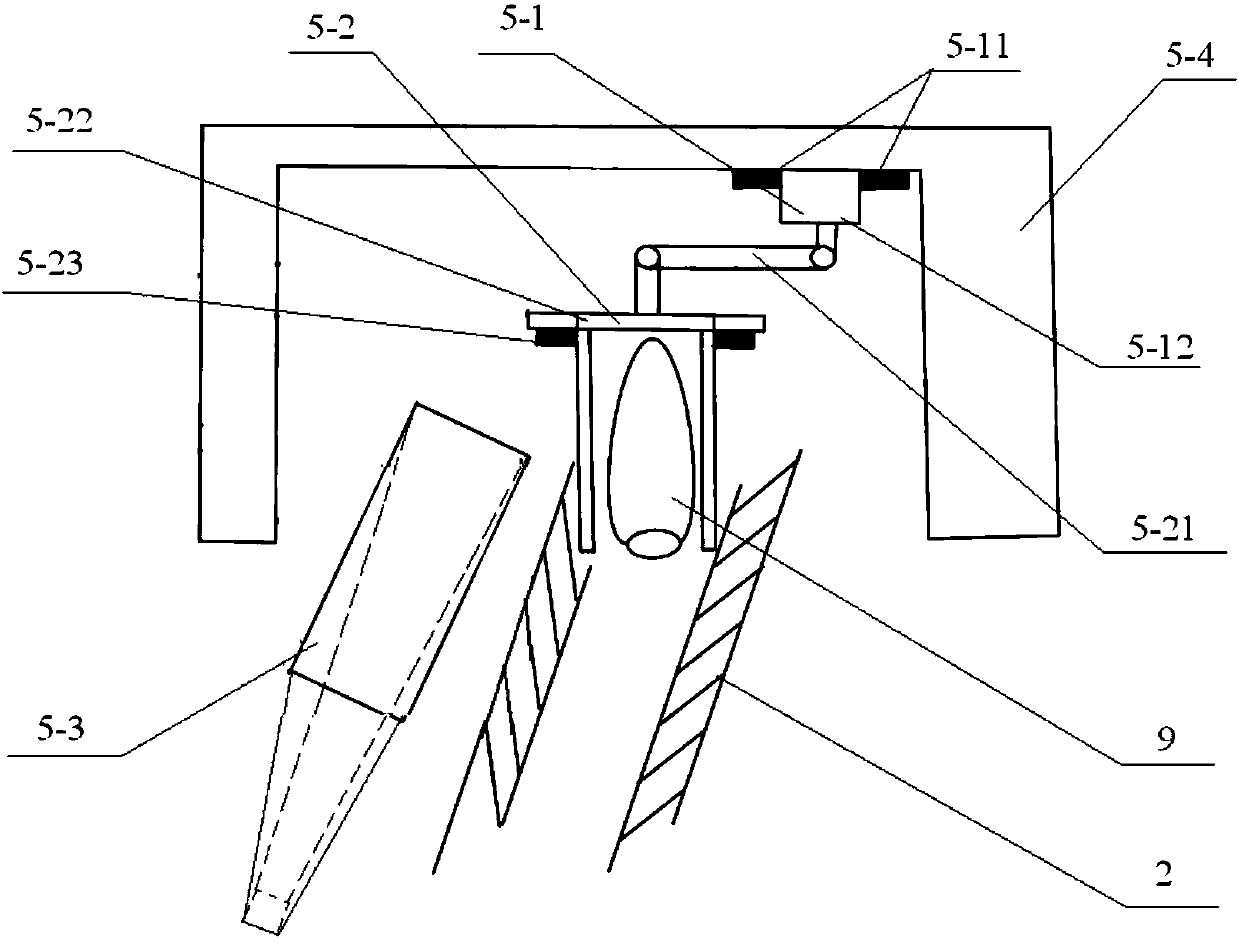

[0018] Such as Figure 1-4 Shown: the glass security profile automatic cutting instrument, including the instrument body 1, the transmission track 2, the first working chamber 3, the second working chamber 4, the third working chamber 5 and the control interface 6; the front end of the instrument body 1 is set to control Interface 6, the upper end is provided with a transmission track 2 along the circumference of the instrument body 1; the first working compartment 3, the second working compartment 4 and the third working compartment 5 are sequentially set on the transporting track 2, wherein the second working compartment 4 and the third working compartment 5 adjacent to each other, and the first working chamber 3 is arranged opposite to the second working chamber 4 and the third working chamber 5.

[0019] The first working warehouse 3 includes a first warehouse cover 3-3, a hydraulic rod 3-1 and an ampoule collecting pipe 3-2; the first warehouse cover 3-3 is arranged above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com