Laminate polymer battery automatic code-spurting rotating disc type flaring detection machine

A soft-pack battery and turntable technology, which is applied in the direction of measuring electricity, typewriters, measuring devices, etc., can solve the problems of unfavorable production development of enterprises, staying in manual processing, and occupying workshop space, so as to shorten invalid time, reduce cost, and increase production capacity. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

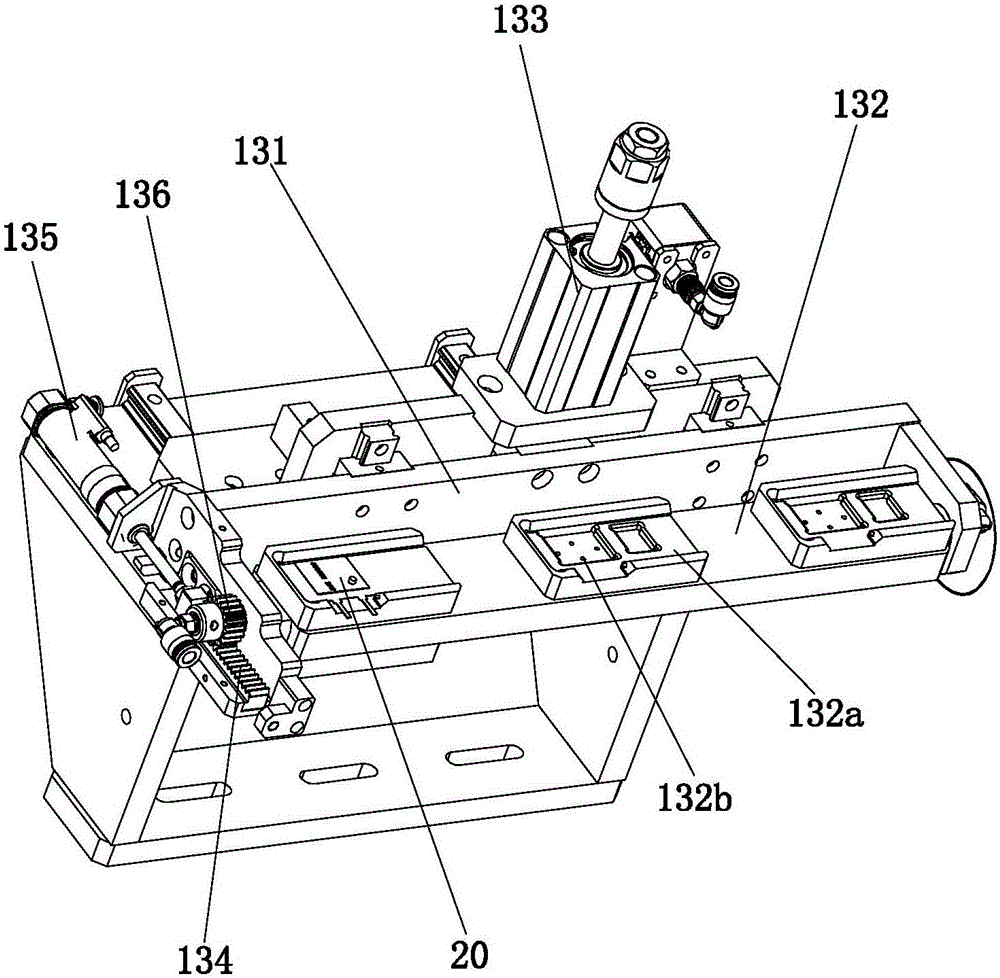

[0032] Such as figure 1 As shown, it is a structural diagram of a soft-pack battery automatic code-spraying turntable-type expanding detector 10 according to an embodiment of the present invention. A soft-pack battery automatic coding-spraying turntable-type expanding detector 10 includes 20 for automatic inkjet printing device 100 and a turntable flaring detection device 200 for detecting pouch battery 20 .

[0033] combine Figure 2 to Figure 4 As shown, the automatic coding device 100 includes: a linear working line 110, a battery rotating feeding manipulator 120 sequentially arranged on the linear working line 110, a first battery turning part 130, a battery straightening part 140, a battery rotating part 150, The first coding part 160 , the second battery turning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com