Automatic tire-supplying system

A tire and automatic technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of reducing the automation level of automobile assembly lines, high labor intensity of workers, and unfavorable labor costs, so as to save labor costs, save manpower, and reduce labor costs. The effect of job hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in detail below.

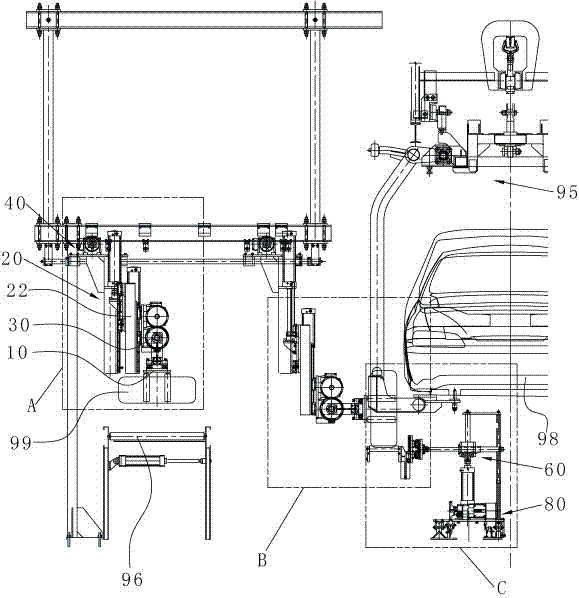

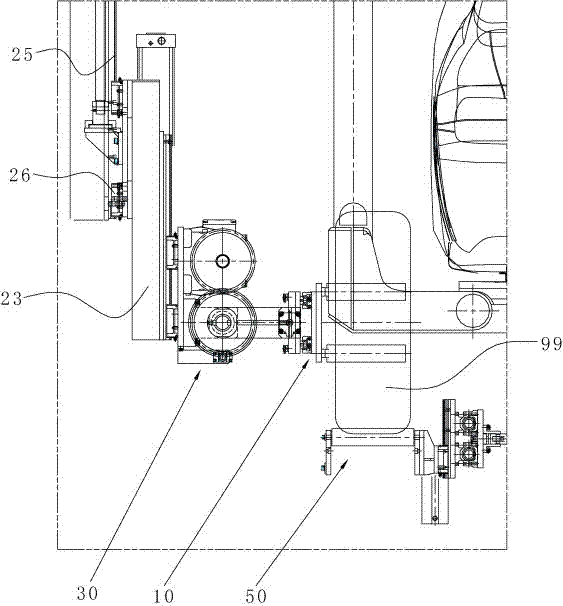

[0024] Such as figure 1 As shown, an automatic tire feeding system of the present invention is arranged above the tire conveying raceway 96 and on the lower side of the automobile assembly line, and is used to automatically transfer the pre-inflated tires 99 on the tire conveying raceway 96 to the automobile assembly line. The wheel hub side of the vehicle body 98 (car body), the tire automatic feeding system includes a clamping device 10 for clamping the pre-inflated tire 99 placed horizontally at the tire delivery raceway 96, and the clamping device 10 is connected and can lift the clamping device 10 and turn it over 90° The lifting and turning device 20 is connected with the lifting and turning device 20 and can lift the clamping device 10 and the lifting and turning device 20 from the tire conveyor roller The moving device 40 above the road 96 moves to the side of the automobile assembly line, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com