Material compositing device and process

A composite device and process technology, applied in the field of machinery, can solve the problems of poor controllability of the tension of elastic composite materials, and achieve the effects of comfortable use, cost reduction and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

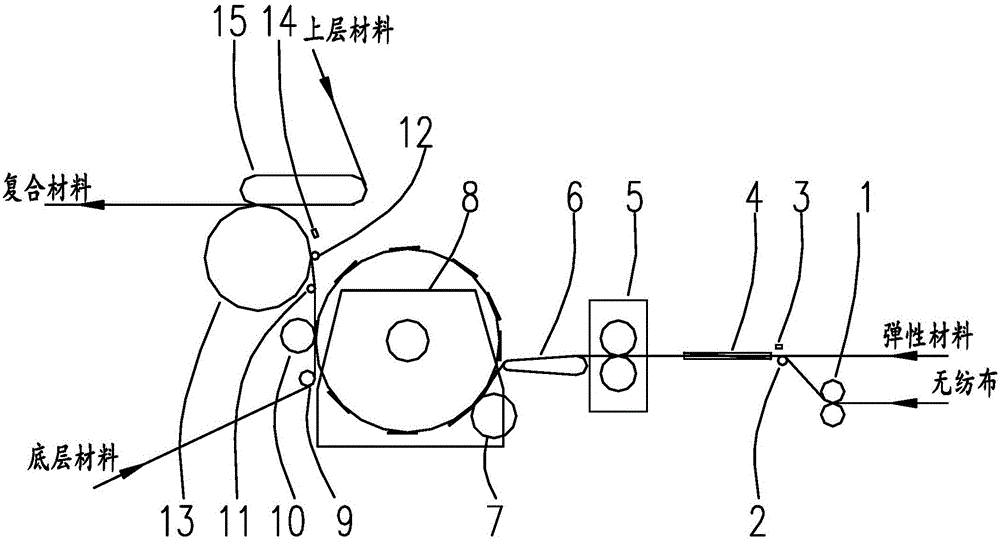

[0029] Such as figure 1 As shown, a compound device for materials includes a traction mechanism 1, a guide roller 2, a first gluing mechanism 3, a folding mechanism 4, a partial cutting and punching unit 5, a first negative pressure conveying mechanism 6, Cutting and turning mechanism 8, guide roller 9, beating mechanism 10, expanding mechanism 11, shaping mechanism 12, second gluing mechanism 14 and transfer wheel 13; the upper part of the transfer wheel 13 is provided with a second negative pressure conveying mechanism 15 ; The beating mechanism 10 includes a cam, and when the cam is attached to the cutting and turning mechanism 8, the material is beating.

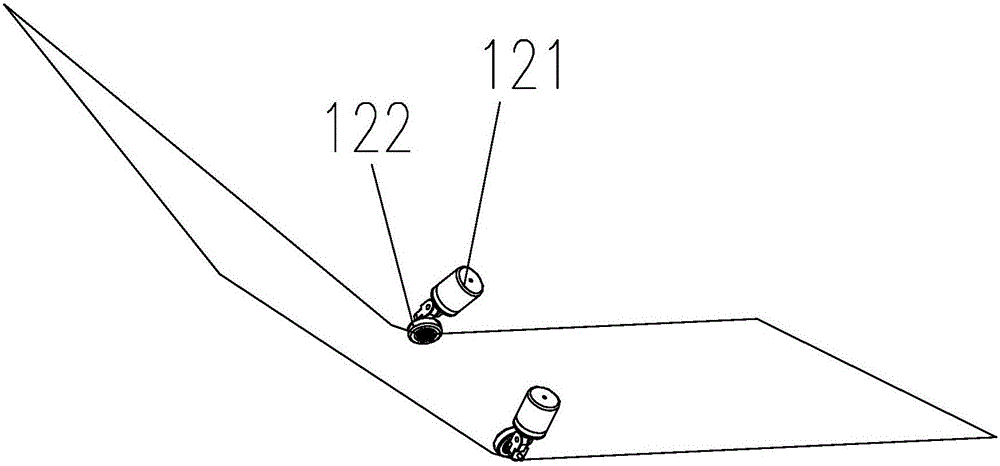

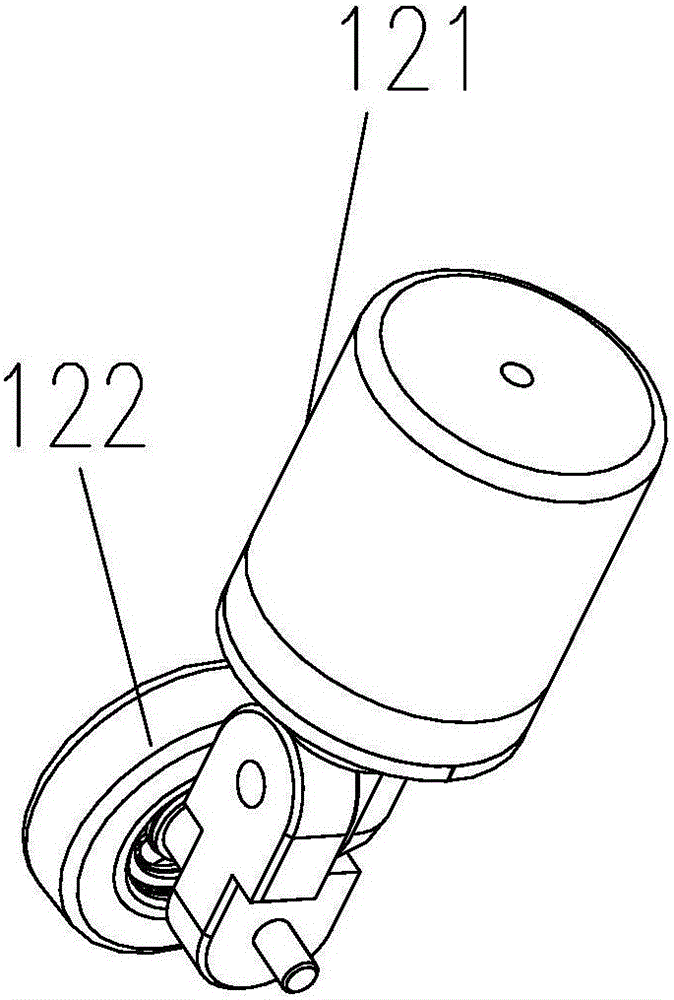

[0030] Specifically, the partial cutting and punching unit 5 includes an upper roller and a lower roller, the surface of the upper roller is provided with protrusions, and the surface of the lower roller is partially provided with grooves matching the protrusions; as figure 2 and 3 As shown, the shaping mechanism 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com