Felling saw

A technology for logging saws and saw chains, which is applied in the field of saw chain structures of logging saws, can solve the problems of rivets such as reduced shear resistance, easy to cause strain, and potential safety hazards, so as to ensure firmness and safety performance, not easy to loosen, and improve The effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

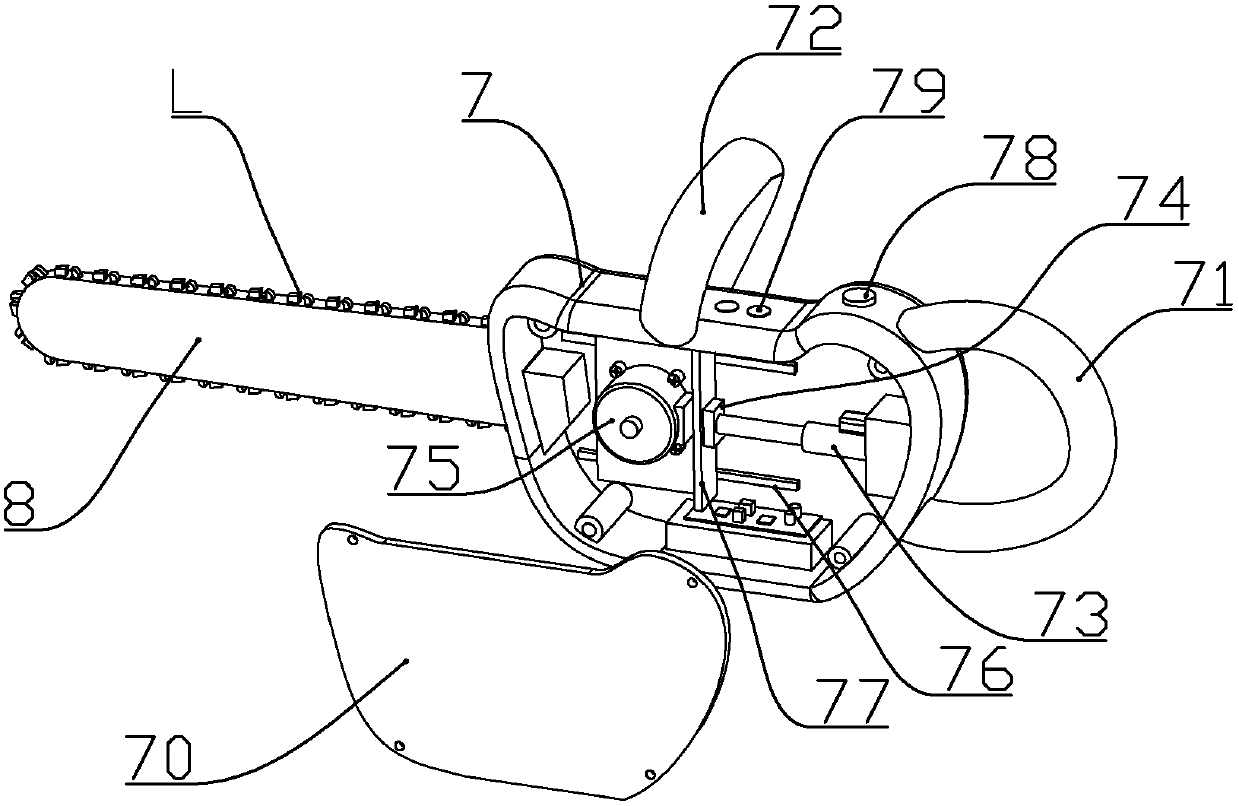

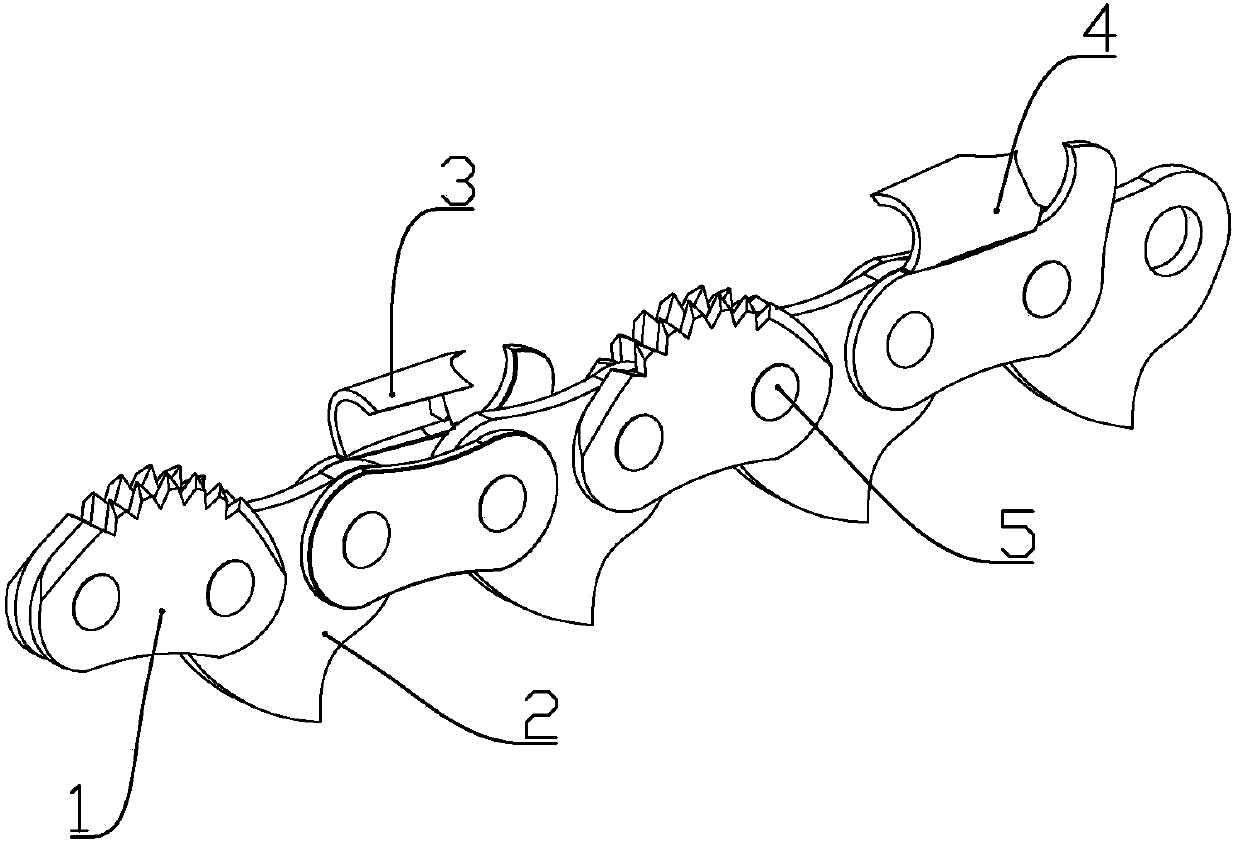

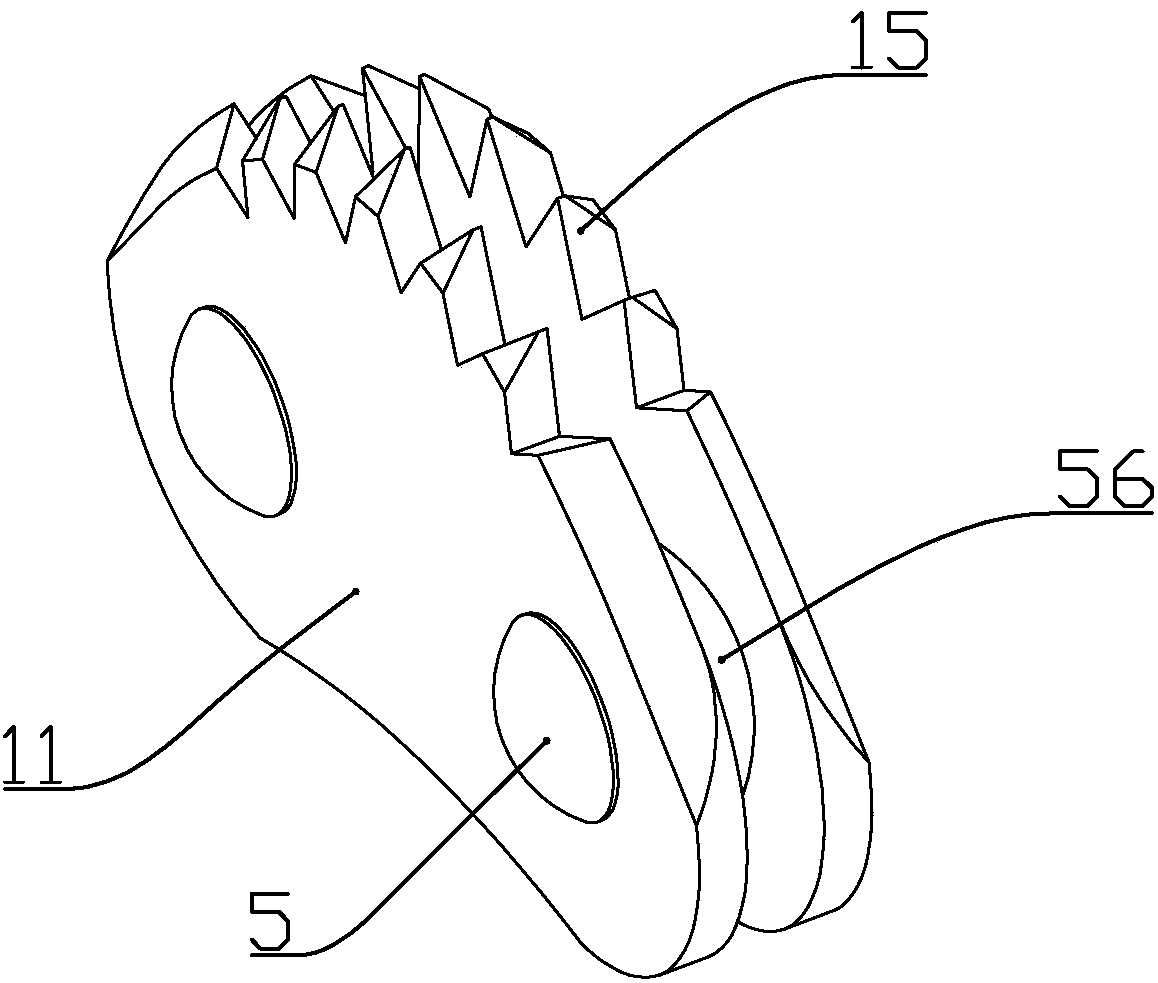

[0038] according to Figure 1 to Figure 14 As shown, this embodiment is a kind of felling saw, including a casing 7 with side openings, a cover plate 70 connected to the side of the casing, a guide rail 76 fixedly installed on the inner wall of the casing and arranged along the front and rear directions of the casing, sliding The mounting plate 77 that is connected on the guide rail, the electric push rod 73 that is connected between the mounting plate and the inner rear part of the casing, the motor 75 that is fixedly connected on the mounting plate and the rotating shaft stretches out to the casing side wall; The guide plate 8 on the outer wall of the casing, the sprocket wheel connected to the front end of the guide plate and the motor shaft, and the saw chain L connected between the two sprocket wheels.

[0039] The side wall of the casing is provided with a strip-shaped hole through which the rotating shaft of the power supply passes and is arranged parallel to the guide ...

Embodiment 2

[0057] The difference between this embodiment and Embodiment 1 lies in the difference of the connecting chain link, the connecting chain link of this embodiment is as follows Figure 15 As shown, the direction indicated by the arrow is the cutting direction of the saw chain, and the distance between the arc-shaped plates on the two connecting pieces of the connecting link gradually decreases along the cutting direction of the saw chain, that is, the distance m at the front of the arc-shaped plate is less than the arc The distance n at the back of the shaped plate, the difference between m and n is between 0.5-1.0mm, so that the cutting teeth on the arc-shaped plate are also in a slightly curved state, and the cuts formed by the cutting teeth on the material to be cut are of great importance to the two connections. Opposite extrusion occurs between the pieces, which can reduce the vibration between the connecting piece and the rivet, and is beneficial to prolong the service life...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com