Cutter for automatically feeding and capable of machining plates with different sizes and machining method thereof

An automatic feeding and cutting machine technology, applied in the field of plate processing, can solve the problems of manual push applicability, etc., and achieve the effect of simple structure and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

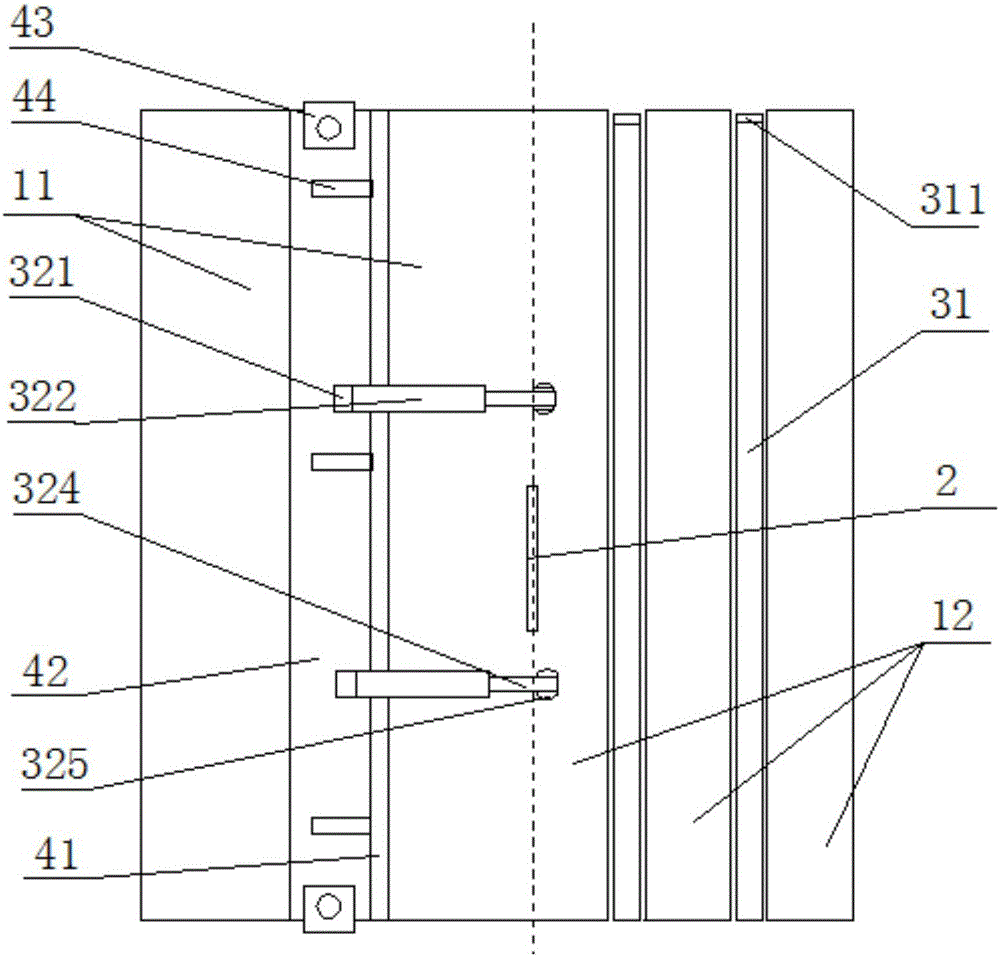

[0058] 2 transmission parts 31 are all fixed on the right workbench 12, as figure 1 shown.

Embodiment 2

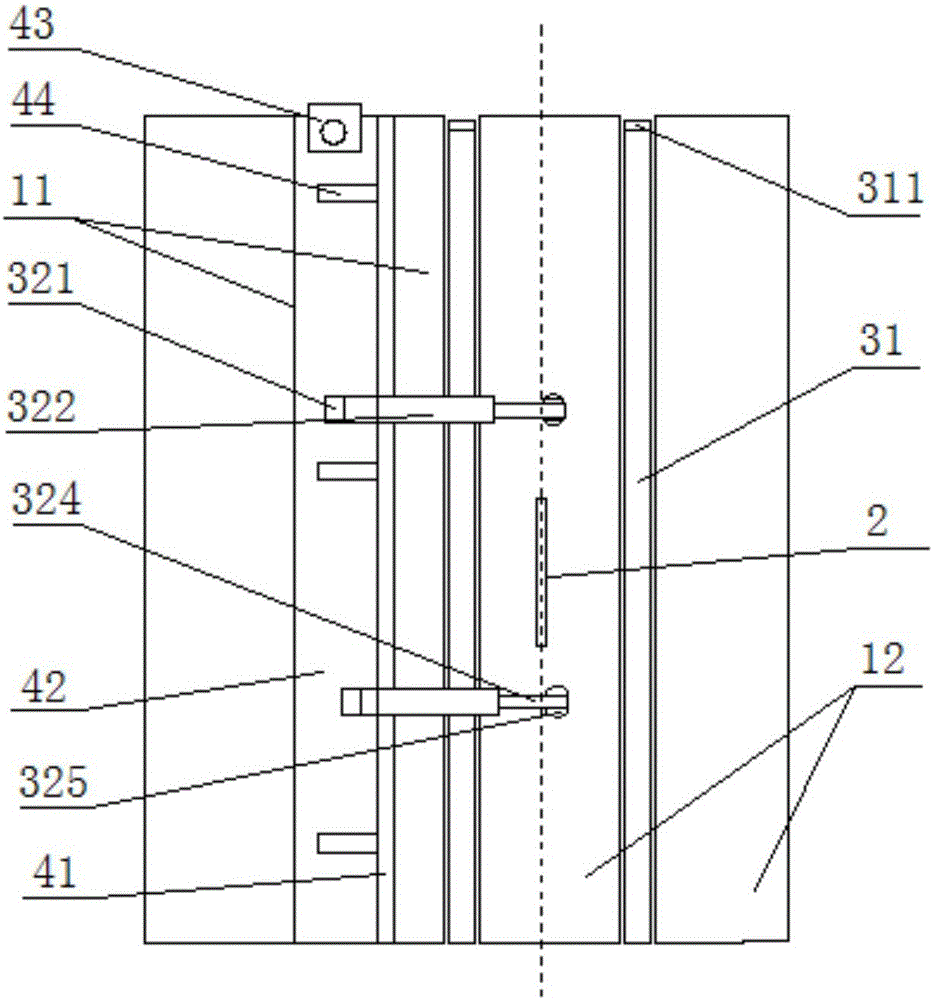

[0060] Or one of the transmission parts 31 is fixed on the left workbench 11, and the other transmission part 31 is fixed on the right workbench 12, as figure 2 shown.

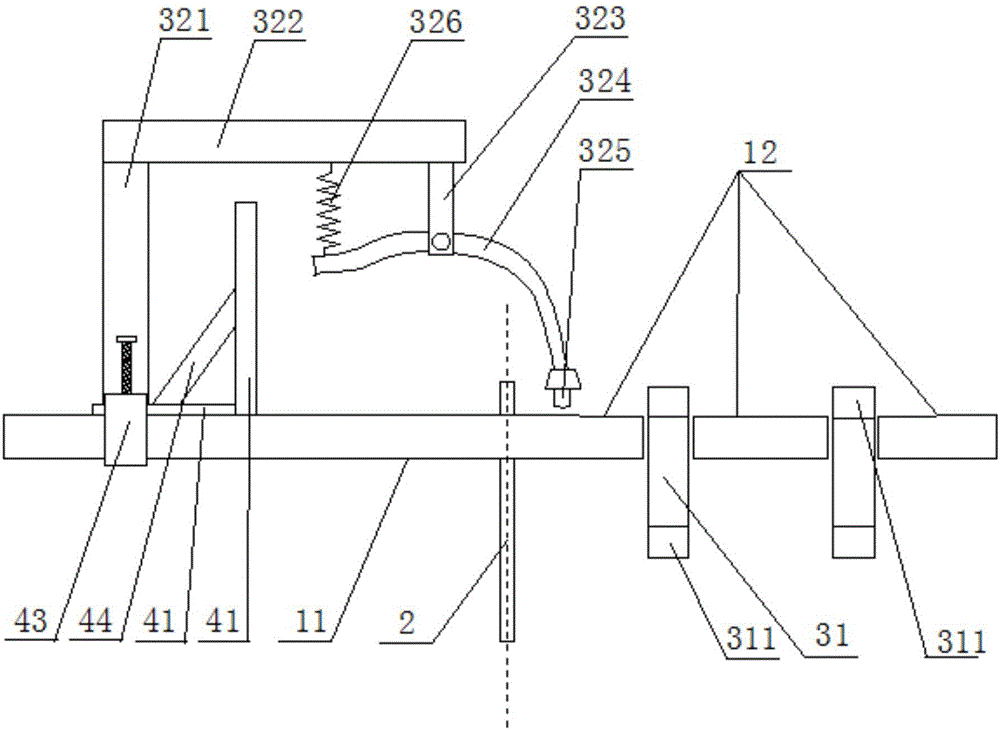

[0061] The conveying part 31 provided by the present invention is a conveying belt; the movement path of the conveying belt is parallel to the grinding wheel saw 2; the upper surface of the conveying belt is lower than or equal to the upper surface of the workbench. It is convenient to ensure the flatness of the board.

[0062] Of course, in order to realize the pushing of the plates, at least the push plate is fixed on the incoming material end of the conveyor belt, that is, the above-mentioned pushing part 311; push plates are fixed at both ends of the conveyor belt to realize the purpose of continuous processing.

[0063] A sheet material processing method of a cutting machine capable of automatically feeding materials and processing sheets of different sizes, comprising the following steps:

[0064] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com