Multi-unit linear driving three-range-of-motion loading robot

A linear drive, linear drive technology, used in loading/unloading, manipulator, transportation and packaging, etc., can solve the problems of weak load capacity and poor dynamic performance, and achieve the effect of improving bearing capacity, reducing energy consumption and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

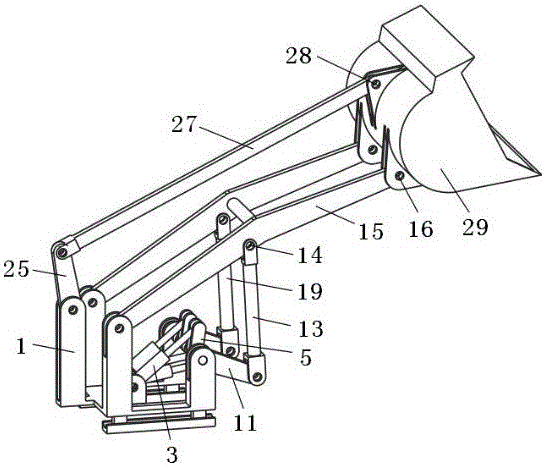

[0026] control figure 1 , a multi-unit linear drive three-degree-of-motion loading robot according to the present invention includes a multi-unit linear drive mechanism, a boom lifting mechanism, a bucket control mechanism and a frame 1 .

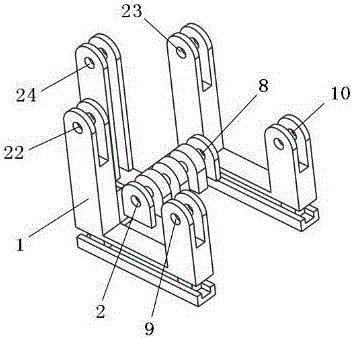

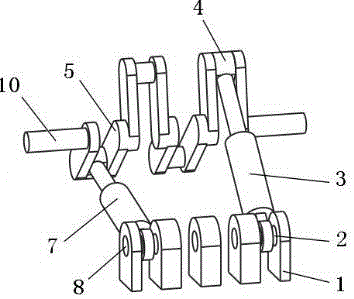

[0027] control figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the multi-unit linear drive mechanism is composed of a first linear driver 3, a second linear driver 7, and a crankshaft 5, and the crankshaft 5 is connected to the frame 1 through the first rotating pair 9 and the second rotating pair 10, and the One end of the first linear drive 3 is connected to the frame 1 through the third rotating pair 2, and the other end is connected to the crankshaft 5 through the fourth rotating pair 4, and one end of the second linear drive 7 is connected to the frame 1 through the fifth rotating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com