Belt-driven three-dimensional translational manipulator

A three-translational and belt-driven technology, which is applied in the direction of manipulators, program-controlled manipulators, and manufacturing tools, can solve the problems of bloated robot structures and large footprints, and achieve compact overall structure, small footprints, kinematics and good dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

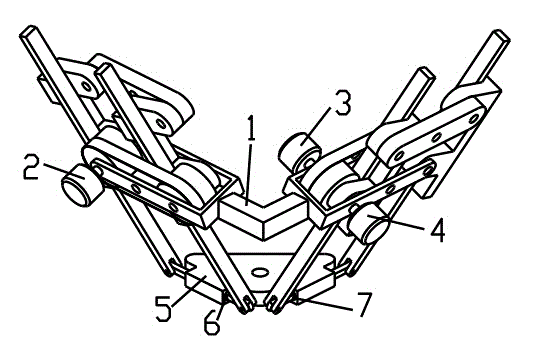

[0020] control figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , The three-translation manipulator with belt transmission includes a frame 1, a first branch chain, a second branch chain, a first motor 2, a second motor 3, a third motor 4 and a moving platform 5.

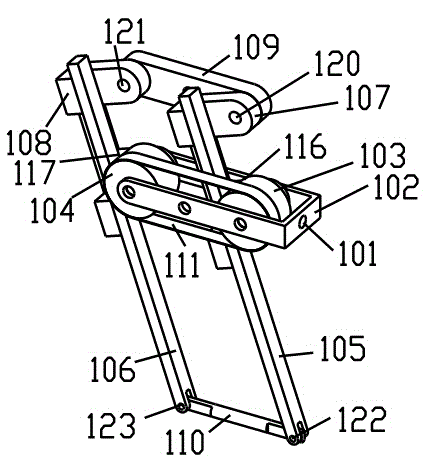

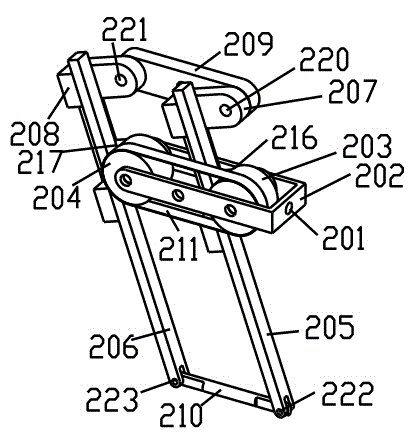

[0021] The first bracket 102 of the first branch chain is connected with the frame 1 through the first rotating pair 101, the first connecting shaft 110 of the first branch chain is connected with the moving platform 5 through the second rotating pair 6, and the The second bracket 202 is connected with the frame 1 through the third rotating pair 201 , and the second connecting shaft 210 of the second branch link is connected with the moving platform 5 through the fourth rotating pair 7 .

[0022] The first branch chain include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com