Rotary clamping manipulator of industrial robot

A technology of industrial robots and manipulators, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high cost, complex manipulator structure, and need to improve the operation accuracy, and achieve low cost, simple structure, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those skilled in the art, other drawings can also be obtained according to these drawings without any creative effort.

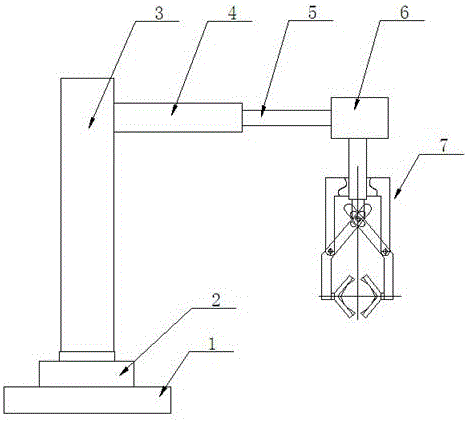

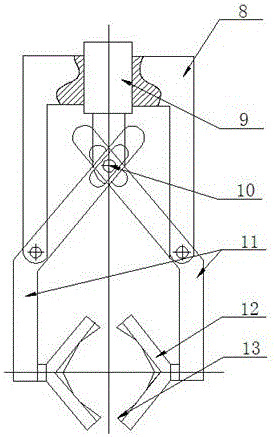

[0016] see as figure 1 —— figure 2 As shown, the specific embodiment adopts the following technical scheme: it includes a chassis 1, a rotating DC motor 2, a support 3, an arm hydraulic cylinder 4, an arm 5, a clamping hydraulic cylinder 6, and a clamping device 7; 2 is fixed on the chassis 1; the upper part of the support 3 is connected with the arm hydraulic cylinder 4, and the support 3 and the arm hydraulic cylinder 4 are connected with the arm 5; one end of the arm 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com