Internal spray booster type grinding wheel rod

A grinding wheel and screw supercharging technology, applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as affecting machining accuracy and grinding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

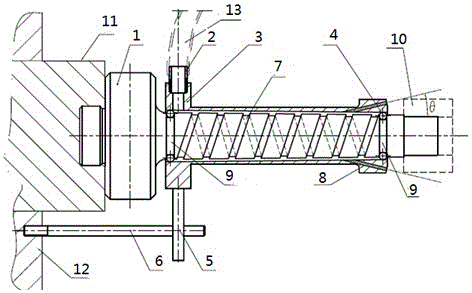

[0010] The following is attached figure 1 Specific embodiments of the present invention will be described.

[0011] see figure 1 ,, This internal spray supercharged grinding wheel rod adopts a unique internal supercharged cooling structure design, which is composed of the following parts, including 1 grinding wheel body 1, 1 water inlet joint 2, 1 jacket 3, 2 O-shaped seals Circle 4, 1 blocking lever 5, 1 driving lever 6. The jacket 3 is set on the grinding wheel rod body 1, and the two ends are installed in the sealing ring groove 9 of the grinding wheel rod body 1 through the O-shaped sealing ring 4 for sealing. There is an overflow gap between the grinding wheel rod body 1 and the jacket 3, and the grinding wheel There is a spiral booster groove 7 on the surface of the rod body 1, and a water inlet joint 2 is connected to the outside of the rear end of the jacket to introduce cooling liquid into the overflow gap. The front end of the jacket is provided with a water spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com