Clamp for disassembling spin lock for container

A technology of containers and fixtures, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of artificial safety threats and high costs, and achieve the effect of increasing appearance, increasing safety protection, and large movable stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

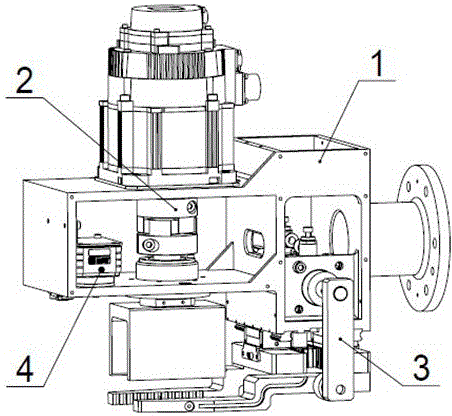

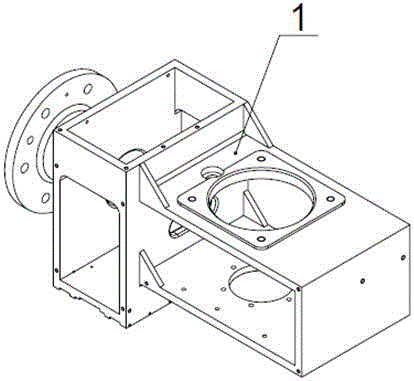

[0031] The clamp used for unloading containers of the present invention includes a clamp body I1, a twist device I2, a clamping device 3, a vision device 4, an upper casing I5 and a lower casing I6. Such as figure 1 As shown, the twist lock fixture 1 includes a fixture body I1, a twisting device I2, a clamping device 3, and a visual device 4, and the twisting device I2, the clamping device 3, and the visual device 4 are all mounted on the clamp body I 1, the visual device 4 and the clamping device 3 are respectively arranged on the left and right sides of the twisting device 2. Such as figure 2 As shown, the fixture body I1 is provided with various interfaces for the installation of the rotary device I2, the clamping device 3, and the visual device 4. The axis of the device I 2 is vertical, and the connecting flange can be connected with the end flange of the robot.

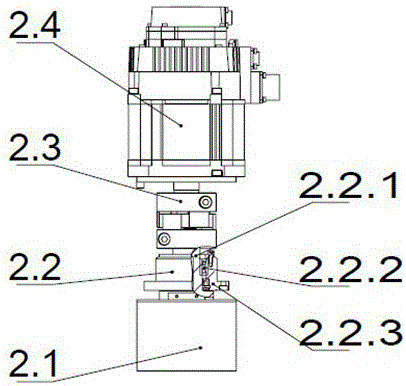

[0032] Such as image 3 As shown, the twisting device I 2 includes a twisting head 2.1, a transmission st...

Embodiment 2

[0037] The fixture in this embodiment includes a fixture body II1a, a twisting device II2a, a clamping device 3, a vision device 4, an upper casing I5a and a lower casing I6a. The positional relationship of the clamping device 3 , the visual device 4 , the clamp body II 1a , the upper case 5a and the lower case 6a is the same as that in the first embodiment. The structures of the clamping device 3 and the visual device 4 are the same as those in the embodiment. This example is used to unload 20

[0038] The 20-foot container group has internal twistlocks, and the robot needs to be installed in the container group, so the action of unloading the twistlocks is different and the internal space is small, so the twistlock fixture II was developed. The servo motor 2.4 of the twistlock fixture II is perpendicular to the axis of the twisting head , combined below Figure 6~Figure 8 Example 2 Twistlock Clamp II is described.

[0039] Such as Figure 6 As shown, the basic principle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com