Numerical control stone thin plate cutting machine

A cutting machine and cutting mechanism technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of low degree of automation, cutting pressure saw blade breakage, saw blade breakage, etc., to save stone resources and reduce production. Cost and human resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

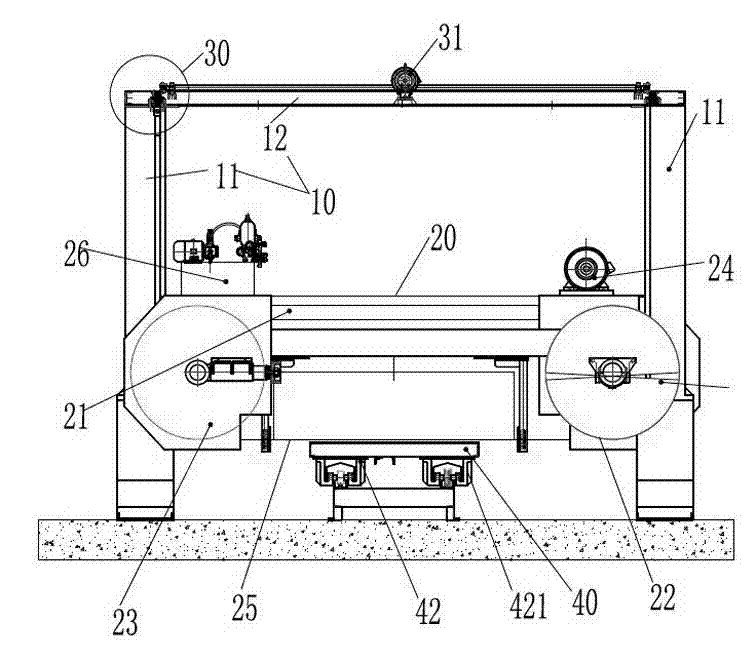

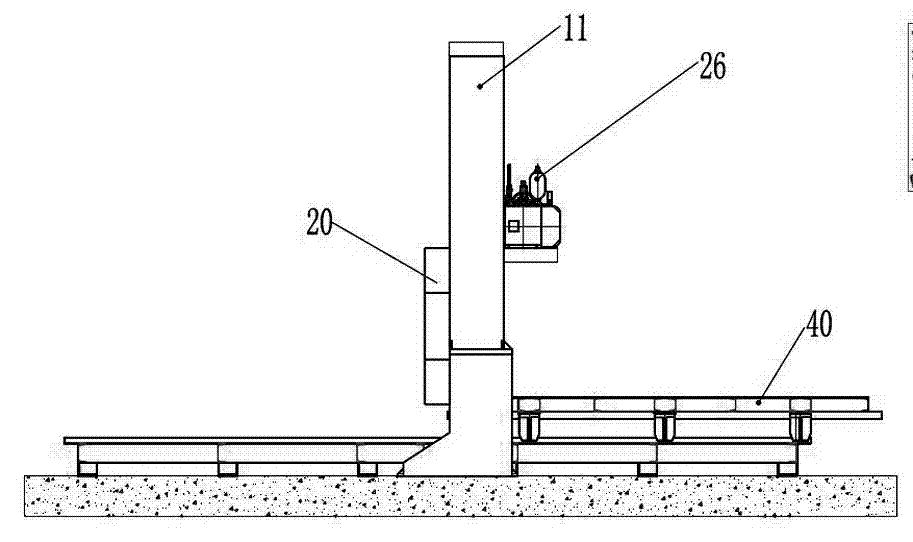

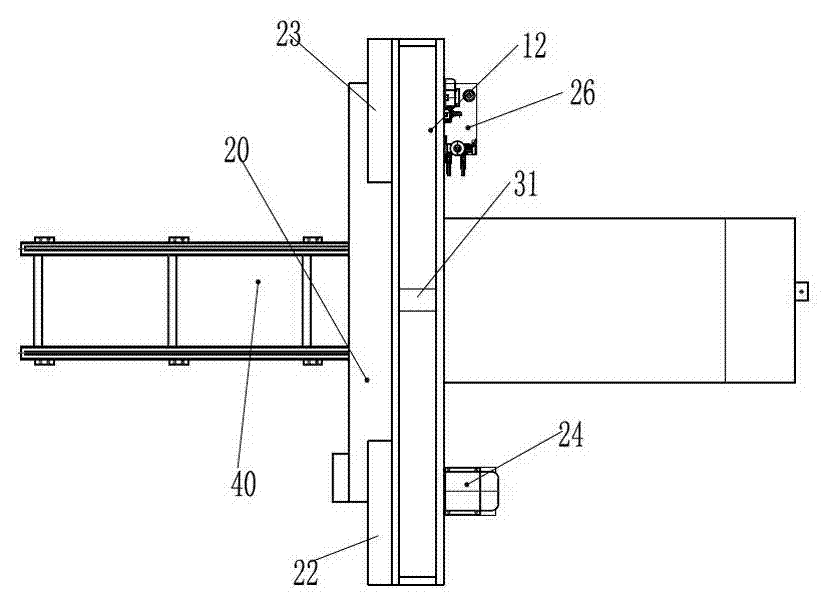

[0031] Such as Figure 1-5 As shown, the numerical control stone thin plate cutting machine disclosed in the preferred embodiment of the present invention includes a machine base for carrying the numerical control stone thin plate cutting machine. The seat top beam 12 and the machine base 10 are provided with a stone thin plate cutting mechanism 20 located below the machine seat top beam 12 .

[0032] During specific implementation, the stone sheet cutting mechanism 20 includes a horizontal guide column 21 for carrying the stone sheet cutting mechanism 20, and the horizontal guide column 21 is equipped with an active saw wheel 22, a passive saw wheel 23 and an active power motor that drives the active saw wheel 22 to rotate. 24, be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com