Direct-current electric heating marshmallow maker

A DC motor and direct current technology, applied in confectionery, confectionery industry, food science and other directions, can solve problems such as hidden safety hazards and difficulty in guaranteeing the quality of marshmallows at high and low temperature, and achieve the effect of ensuring quality, convenience and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: The DC motor and the rotating shaft are connected by belt transmission.

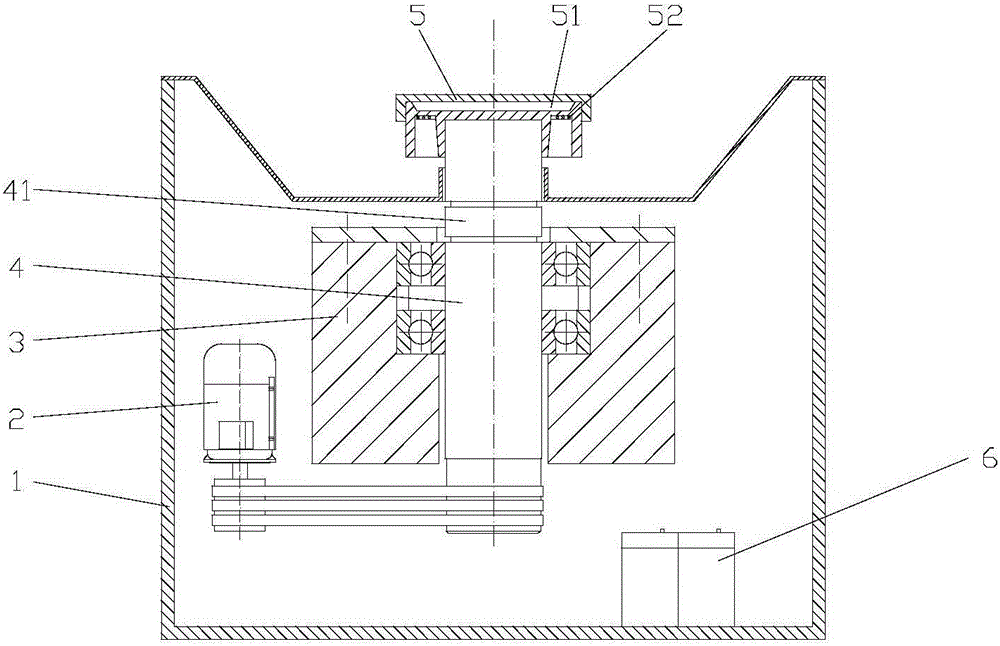

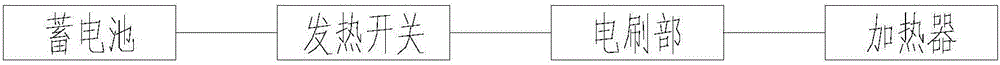

[0014] figure 1 It is a structural schematic diagram of a direct current heating cotton candy machine adopting belt transmission in the present invention. figure 2 It is a schematic diagram of the electrical connection of the heater of a direct current heating cotton candy machine. It can be seen from the figure: a DC electric heating cotton candy machine, including a frame (1), a DC motor (2), a rotating shaft (4), a rotating shaft fixing device (3), a sugar dispenser (5), and a battery (6) ;

[0015] In order to ensure the convenience and safety of the cotton candy machine, the storage battery (6) is electrically connected to the DC motor (2); the rotating shaft (4) is arranged on the rotating shaft fixing device (3) through a bearing, and the rotating shaft (4) One end is connected to the DC motor (2) through a belt drive, the other end is provided with a sugar dispenser (5), and the...

Embodiment 2

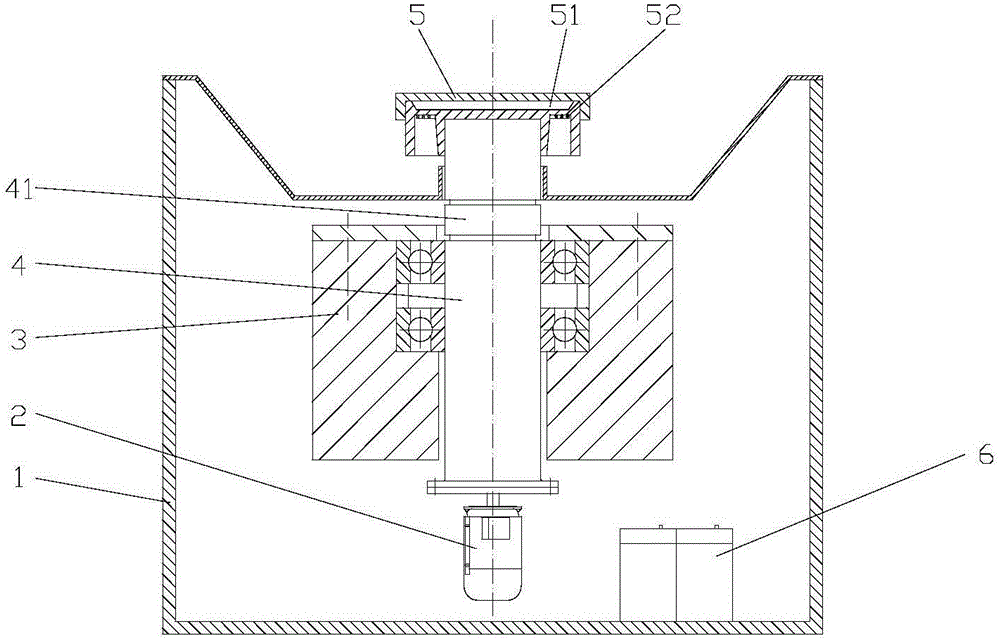

[0019] Embodiment 2: The DC motor and the rotating shaft are connected by flanges.

[0020] figure 2 It is a schematic diagram of the electrical connection of the heater of a direct current heating cotton candy machine, image 3 It is a schematic diagram of the structure of a DC electric heating cotton candy machine adopting flange transmission. It can be seen from the figure: a DC electric heating cotton candy machine, including a frame (1), a DC motor (2), a rotating shaft (4), a rotating shaft fixing device (3), a sugar dispenser (5), and a battery (6) ;

[0021] In order to ensure the convenience and safety of the cotton candy machine, the storage battery (6) is electrically connected to the DC motor (2); the rotating shaft (4) is arranged on the rotating shaft fixing device (3) through a bearing, and the rotating shaft (4) One end is connected to the DC motor (2) through a connecting flange, the other end is provided with a sugar dispenser (5), and the rotating shaft (4) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com