Environment-friendly material-saving device for sulfuric acid rolling of smeared unformed plates through rolling dipping of rich solution with barren solution

A green electrode plate and rolling technology, applied in electrode rolling/calendering, electrode manufacturing, lead-acid battery electrodes, etc., can solve the problem of uneven rolling of surface acid, thickness of lead sulfate layer, and surface of lead paste on green electrode plate cracks and other problems, to achieve the effect of reducing the service life, uniform and moderate acid thin layer, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

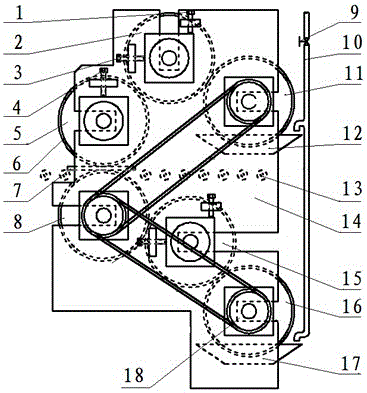

[0032] Such as figure 1 Shown, the present invention comprises up and down rolling and dipping roller 11,16, up and down transfer roller 2,15 and up and down rolling pressure roller 5,8, and described up and down rolling and dipping roller 11,16 dips and rolls up and down and dips in the acid tank that rolls up and down below it respectively 12, 17, then respectively contact with the upper and lower transfer rollers 2, 15 for transmission and rolling, and the upper and lower transfer rollers 2, 15 respectively contact with the upper and lower rolling rollers 5, 8 for transmission and rolling, and the gap between the upper and lower rolling rollers 5, 8 is set, The raw electrode plate conveying raceway 13 is arranged in the gap, and the roller surfaces of the upper and lower rolling dipping rollers, the upper and lower transfer rollers and the upper and lower rolling rollers are all wrapped with 5-7 layers of acid-absorbing resistant roller cloth 6 .

[0033] There are three sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com