Control method of flow of reducing agent in flue gas SNCR denitration process

A control method and technology of reducing agent, which are applied in various fluid ratio control, non-electric variable control, ratio control and other directions, can solve the problem that the correction parameters do not meet the extreme working conditions, the cost is high, the first CEMS and the first ammonia meter Difficulty in selection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

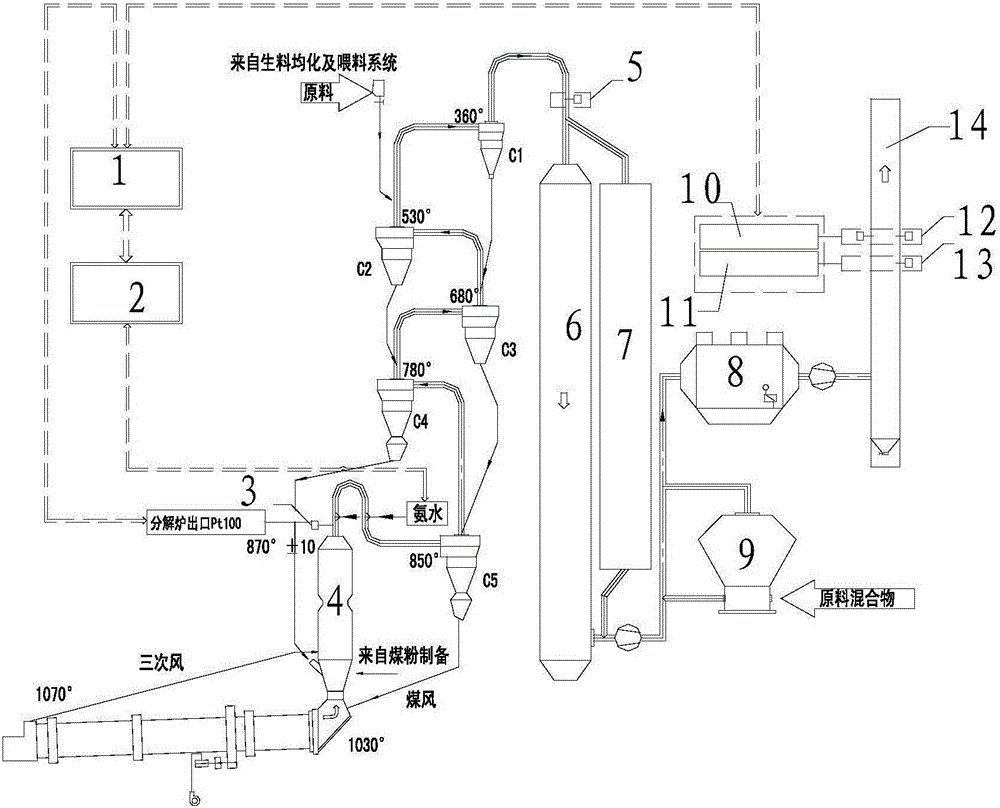

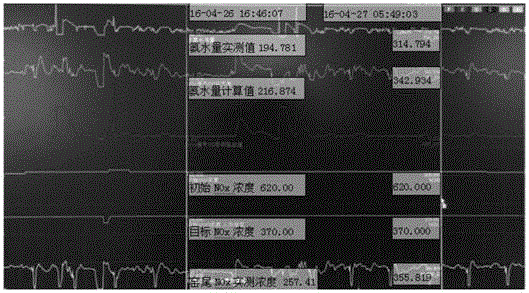

[0063] as attached figure 1 As shown, the specification is the SNCR denitrification reducing agent metering system for the calciner of the clinker production line with a daily output of 5000t, and ammonia water is used as the reducing agent. The decomposition furnace is equipped with a Pt100 temperature probe, and the outlet of the C1 preheater is equipped with a CO analyzer, and the signal is sent to the denitration system. The composition diagram of the denitration control system is as follows image 3 shown.

[0064] Before the construction of the denitrification device, due to the requirements of environmental protection supervision, a chimney CEMS was installed, and the flue gas indicators include: flue gas flow, NOx, SO 2 , dust, temperature, humidity, O 2 . When carrying out SNCR flue gas denitrification transformation, a chimney ammonia escape detector is added on the same floor as the chimney CEMS sampling probe, and all flue gas parameters are sent to the denitrif...

Embodiment 2

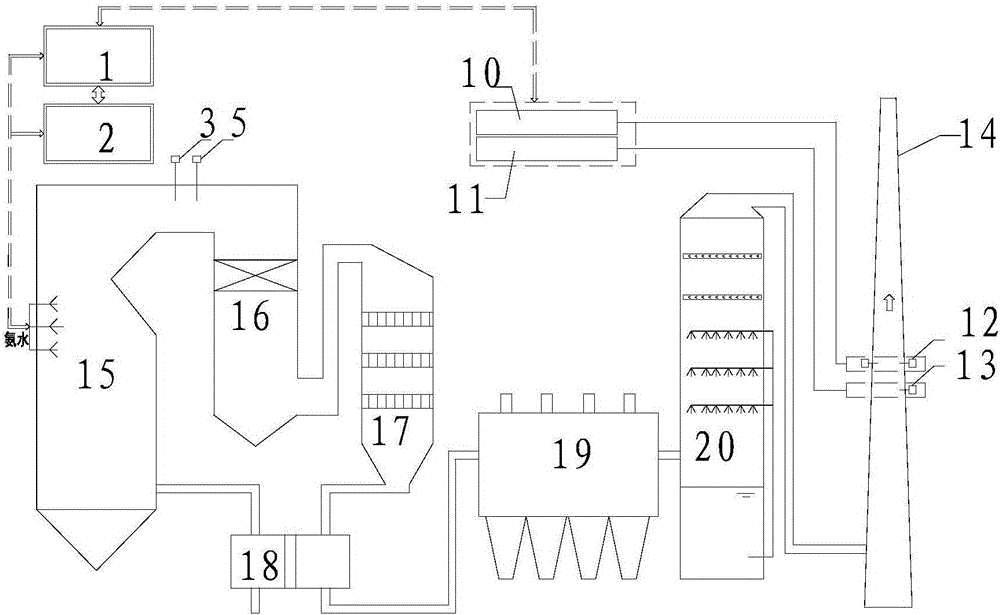

[0070] as attached figure 2 As shown, the SNCR denitrification reducing agent metering system of a circulating fluidized bed boiler (CFB) with a specification of 130 tons / hour uses ammonia water as the reducing agent. The furnace economizer is equipped with a Pt100 temperature probe and a CO analyzer, and the signal is sent to the denitrification system. The composition diagram of the denitrification control system is as follows image 3 shown.

[0071]Before the construction of the denitrification device, due to the requirements of environmental protection supervision, a chimney CEMS was installed, and the flue gas indicators include: flue gas flow, NOx, SO 2 , dust, temperature, humidity, O 2 . After the SNCR flue gas denitrification transformation, a chimney ammonia escape detector is added to the same platform as the chimney CEMS sampling probe, and all flue gas parameters are sent to the denitrification control system.

[0072] The input parameters for calculating th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com