Method for evaluating permeating performance of chemical imbibition agent

An evaluation method and a technology of permeability performance, which is applied in the field of evaluation of the permeability performance of chemical absorbents, can solve problems such as lack of methods, and achieve the effect of easy comparison and quantification, and convenient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

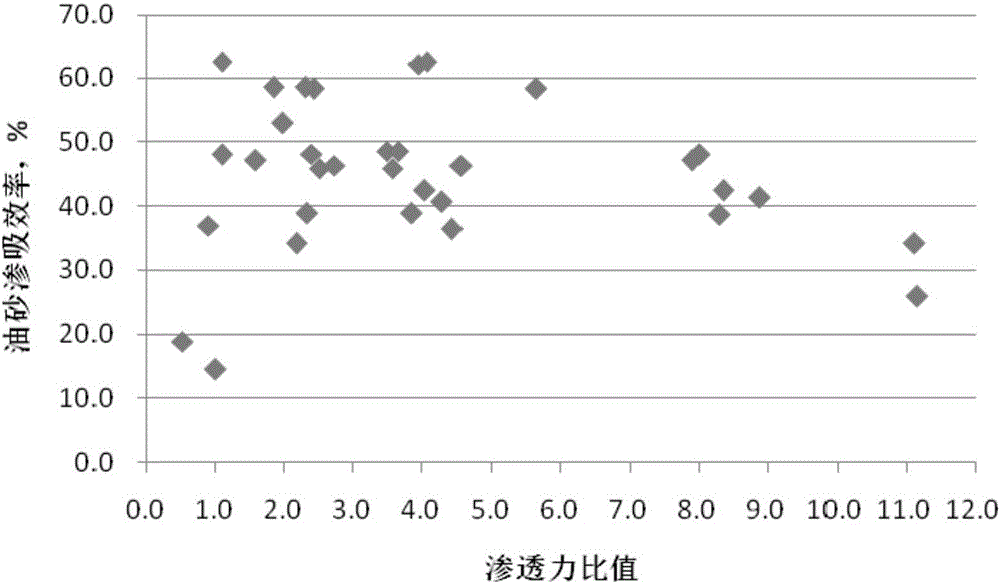

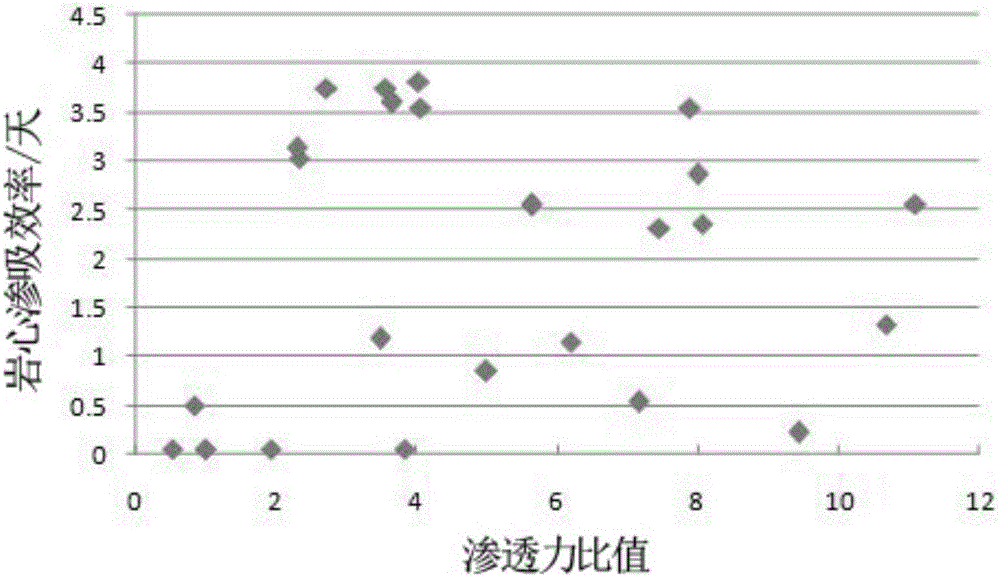

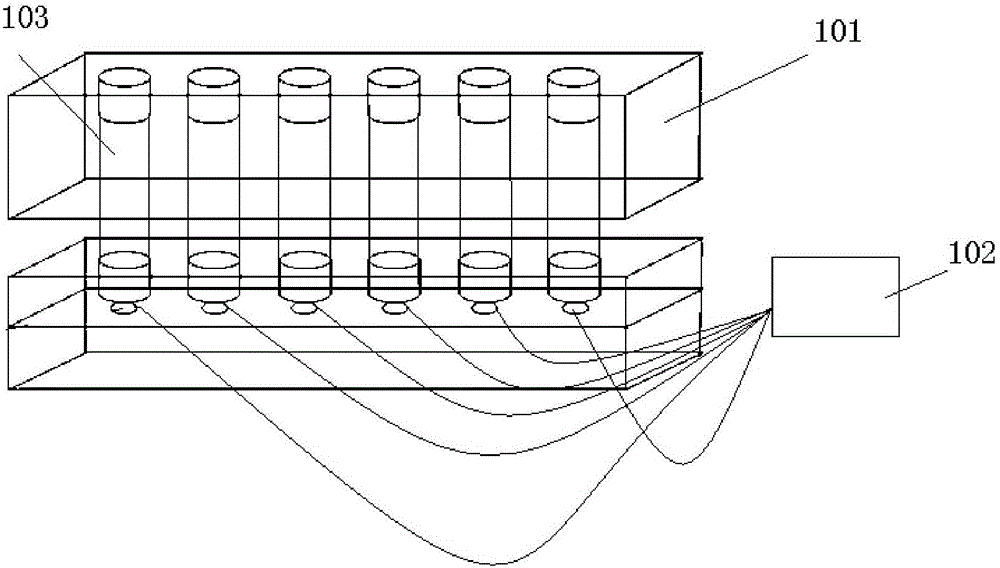

[0052] This embodiment provides a method for evaluating the permeability of chemical imbibants, mainly by measuring the permeability values of various chemical imbibants and formation simulated water, and comparing and judging the permeability of chemical imbibants in the target oil reservoir. The definition formula of penetration force: penetration force (Fp) = capillary lift coefficient (Sc) × penetration velocity (Sp), to measure the capillary lift coefficient and penetration velocity value of the chemical imbibant, the specific test experiment includes the following steps:

[0053] A. Penetration speed (Sp) test:

[0054] (1) Oil sand selection and preparation:

[0055] According to the reservoir permeability Ka of the target oil reservoir, select quartz sand or natural sand with a corresponding particle size range, and mix crude oil or simulated oil of the target oil reservoir with the quartz sand or washed natural sand to make oil sand;

[0056] When Ka>800mD, choose ...

Embodiment 2

[0114] This example provides a method for evaluating the permeability of a chemical absorbent, the steps of which are the same as in Example 1.

[0115] The 5 groups of experiments in this embodiment are to simulate the reservoir conditions of YT oilfield. The experiment uses fine oil sand (100-160 mesh) oil sand, and the experimental temperature is 64 ° C. This oilfield belongs to the ultra-low permeability reservoir (Ka=1.0-10mD ). The oil sand preparation and capillary treatment are the same as in Example 1, the inner surface of the capillary is treated to an oil-wet state, and the testing method is the same as in Example 1. The test method for the penetration rate of the graduated tube is the same as in Example 1, and the experimental results are shown in Table 6, Table 7, and Table 8.

[0116] See Table 6 for the capillary test, Table 7 for the calibration tube penetration velocity test, and Table 8 for the calculation results of the penetration force.

[0117] Table 6 ...

Embodiment 3

[0125] This example optimizes the parameter selection of the capillary lift coefficient in the method for evaluating the permeability of the chemical absorbent of the present application.

[0126] This example provides the capillary lift coefficients under the conditions of two kinds of formation simulated water and 10 kinds of chemical imbibants using capillary tubes with two inner diameters (0.3mm and 0.5mm), the same wettability (oil wet), and the same conditions of crude oil and water Experiment, the experimental results are shown in Table 9 and Table 10.

[0127] Table 9

[0128]

[0129]

[0130] Table 10

[0131]

[0132] From the experimental results in Table 9 and Table 10, it can be seen that when the same agent or water is tested in capillary tubes with the same inner diameter, when the imbibition volume in the liquid-filled small test tube is different (3mL, 4mL, 5mL), the capillary lift coefficient is also different. The trend is that the capillary lift...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com