Preparation device and preparation method for asphalt mixture trapezoidal beam test specimen

A technology for asphalt mixture and production device, which is applied in the direction of measuring device, preparation of test samples, analysis of materials, etc., can solve the problems of poor molding quality, long production cycle, large dimensional error, etc., and achieve good integrity of the test piece. , The effect of short production cycle and reduced cost of processing specimens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

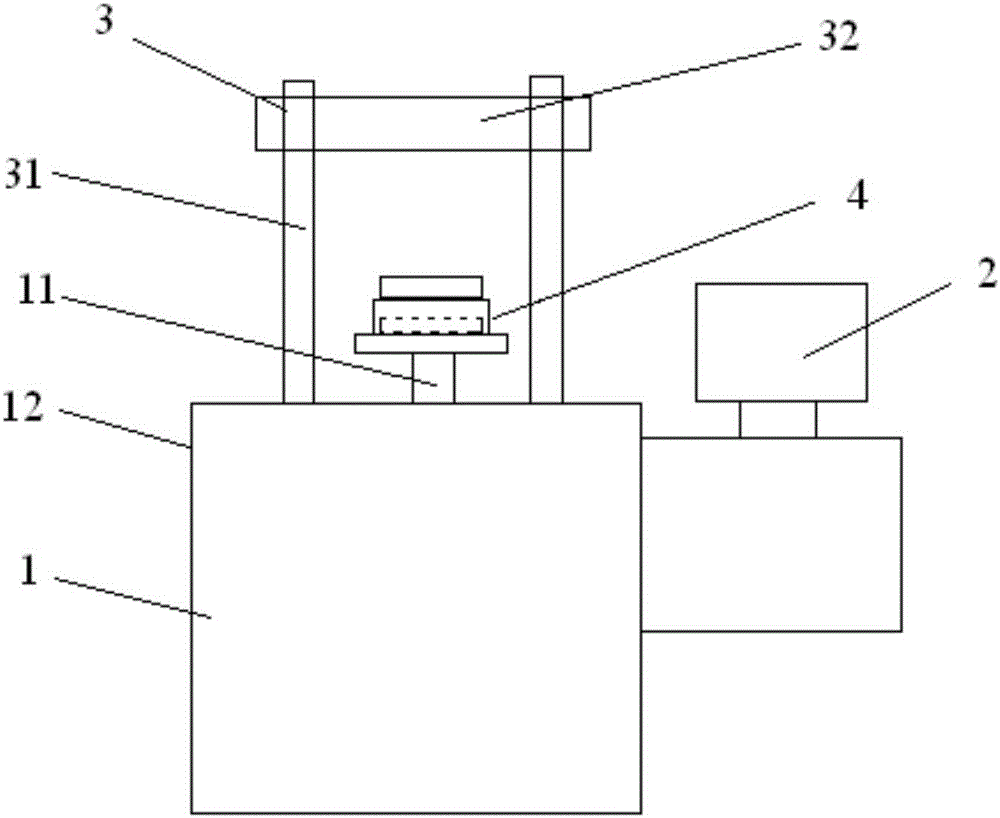

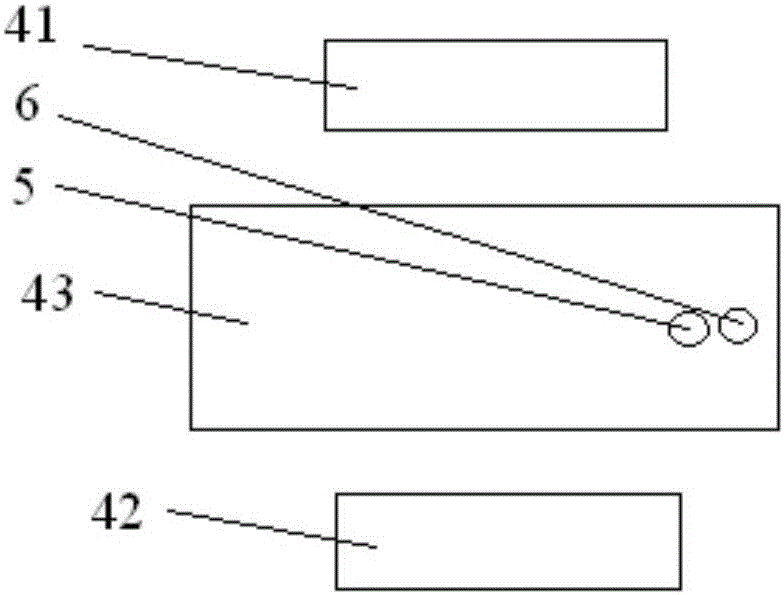

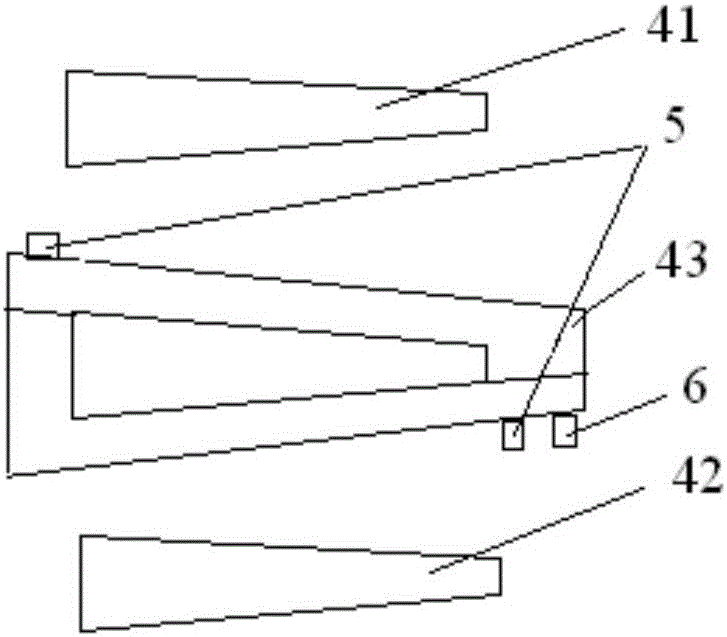

[0058] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

[0059] Explanation of relevant terms involved in the present invention:

[0060] 1. Modulus: It refers to the ratio of the stress to the strain of the material under stress. It originally refers to a mechanical parameter of the material within the elastic limit. Therefore, when no definite article is added, it is often considered to refer to the elastic modulus, that is The ratio of stress to strain is a constant. The size of this value indicates the ability of the material to resist elastic deformation under the action of external force.

[0061] 2. Cementing material: Refers to synthetic polymers or organic mixtures containing asphalt, and viscous s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com