Sewage processing agent and preparation method thereof

A technology of sewage treatment agent and deionized water, which is applied in water treatment parameter control, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problem of poor use effect of sewage treatment agent and high cost problems, achieve excellent flocculation effect, improve clarity, and be easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

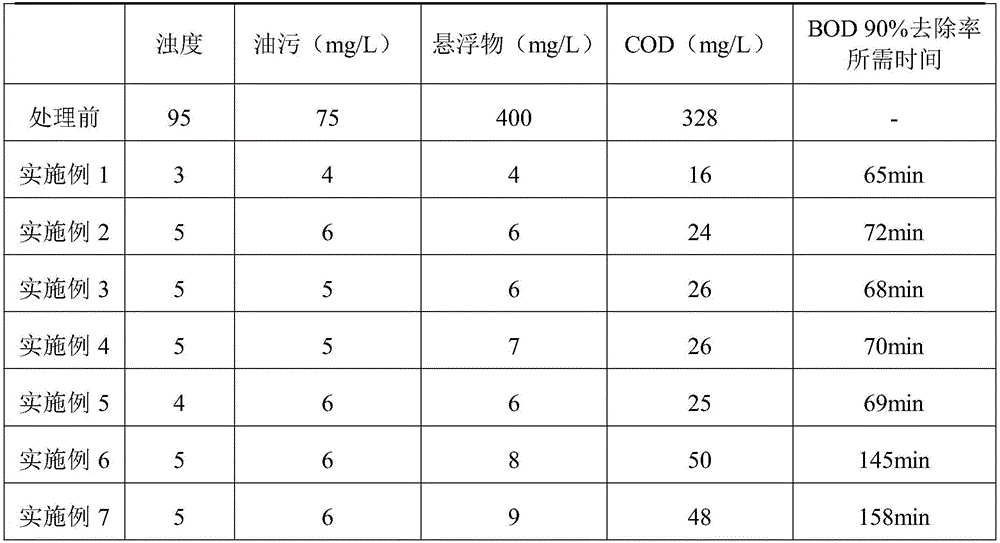

Examples

Embodiment 1

[0025] Embodiment 1: the preparation of sewage treatment agent

[0026] Raw material weight ratio:

[0027] Cationic flocculant, 35 parts; sodium chloride, 35 parts; lithopone, 12.5 parts; polyethyleneimine, 7.5 parts; citric acid, 7.5 parts; zinc oxide, 9 parts; activated carbon, 5 parts; , 7.5 parts; Polyacrylamide, 7.5 parts; Composite synergist, 25 parts; Corn starch, 9 parts; Deionized water, 75 parts; For the mixture of aluminum, the weight part of sodium lignosulfonate is 3 times of the weight part of polyaluminum chloride.

[0028] Preparation:

[0029] Step S1, adding cationic flocculant, zinc oxide and activated carbon into the mixer, adding deionized water and stirring evenly;

[0030] Step S2, adding citric acid to the blender, stirring until uniform while adding;

[0031] Step S3, adding polysilicoaluminum sulfate, polyacrylamide and polyethyleneimine to the mixer, stirring until uniform while adding;

[0032] Step S4, adding corn starch, stirring and reactin...

Embodiment 2

[0035] Embodiment 2: the preparation of sewage treatment agent

[0036] Raw material weight ratio:

[0037] Cationic flocculant, 30 parts; Sodium chloride, 30 parts; Lithopone, 10 parts; Polyethyleneimine, 5 parts; Citric acid, 5 parts; Zinc oxide, 8 parts; Activated carbon, 4 parts; , 5 parts; Polyacrylamide, 5 parts; Composite synergist, 20 parts; Corn starch, 8 parts; Deionized water, 50 parts; Wherein, the composite synergist is sodium lignosulfonate and polychlorinated For the aluminum mixture, the weight part of sodium lignosulfonate is twice the weight part of polyaluminum chloride.

[0038] Preparation:

[0039] Step S1, adding cationic flocculant, zinc oxide and activated carbon into the mixer, adding deionized water and stirring evenly;

[0040] Step S2, adding citric acid to the blender, stirring until uniform while adding;

[0041] Step S3, adding polysilicoaluminum sulfate, polyacrylamide and polyethyleneimine to the mixer, stirring until uniform while adding;...

Embodiment 3

[0045] Embodiment 3: the preparation of sewage treatment agent

[0046] Raw material weight ratio:

[0047] Cationic flocculant, 40 parts; Sodium chloride, 40 parts; Lithopone, 15 parts; Polyethyleneimine, 10 parts; Citric acid, 10 parts; Zinc oxide, 10 parts; Activated carbon, 6 parts; , 10 parts; Polyacrylamide, 10 parts; Composite synergist, 30 parts; Corn starch, 10 parts; Deionized water, 100 parts; Wherein, the composite synergist is sodium lignosulfonate and polychlorinated For the mixture of aluminum, the weight part of sodium lignosulfonate is 4 times of the weight part of polyaluminum chloride.

[0048] Preparation:

[0049] Step S1, adding cationic flocculant, zinc oxide and activated carbon into the mixer, adding deionized water and stirring evenly;

[0050] Step S2, adding citric acid to the blender, stirring until uniform while adding;

[0051] Step S3, adding polysilicoaluminum sulfate, polyacrylamide and polyethyleneimine to the mixer, stirring until unifor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com