Vacuum arc extinguishing chamber transferring and conveying disk

A technology of vacuum interrupter and conveying tray, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of daily management difficulties, achieve the effects of convenient daily management, reduce production costs, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

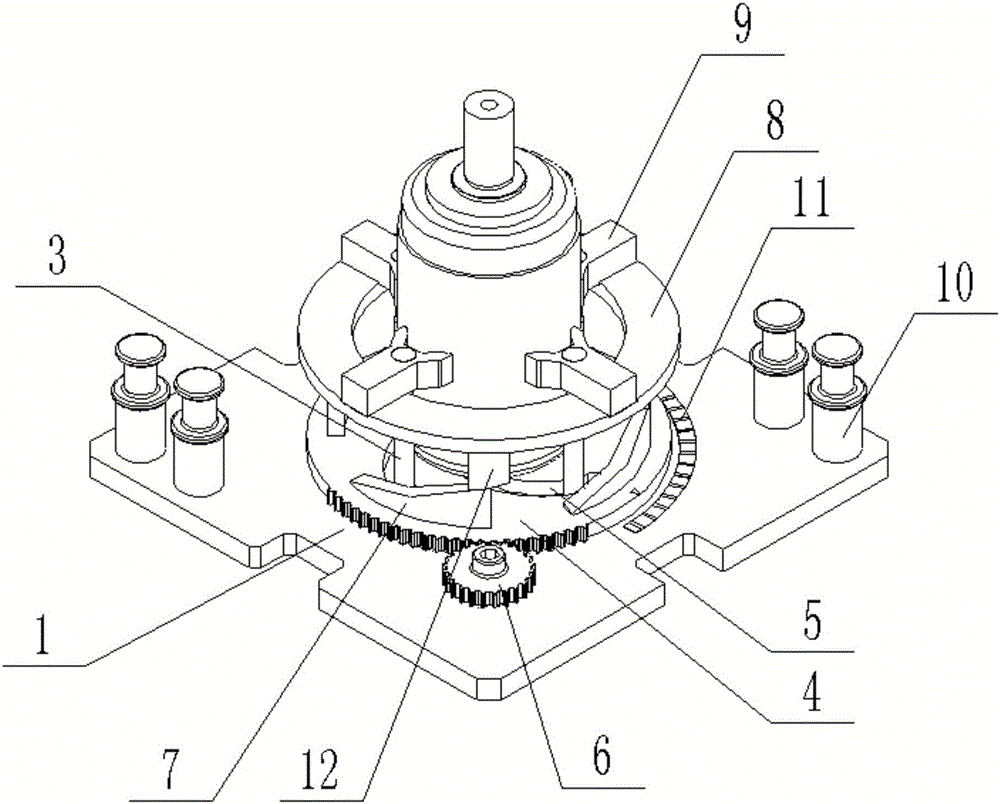

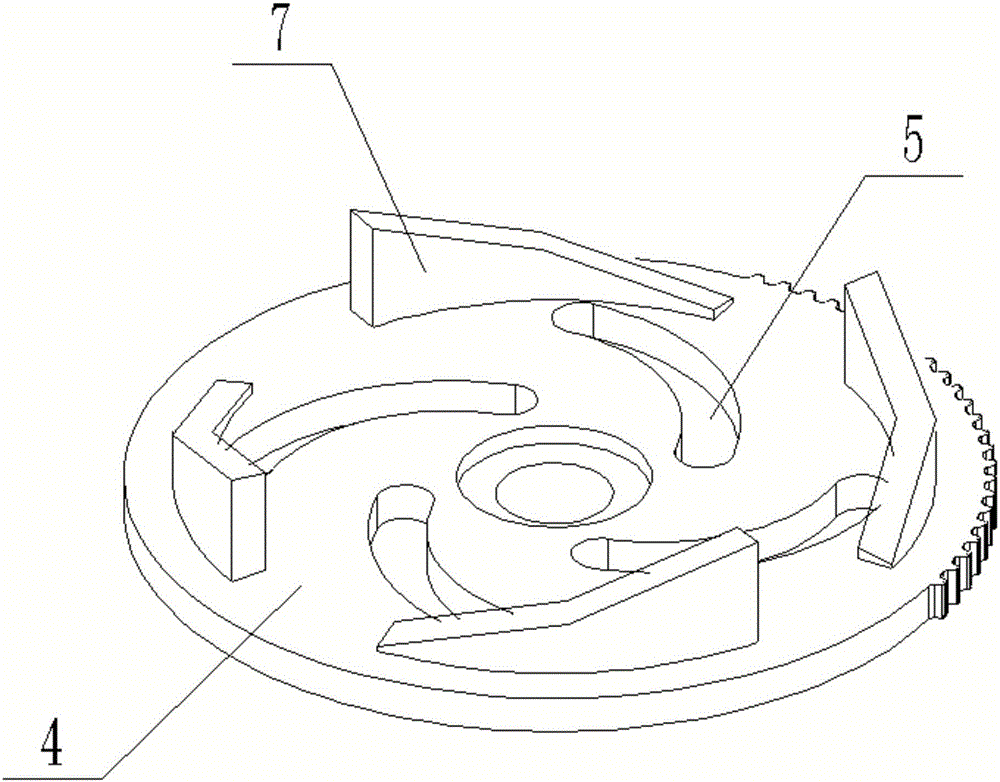

[0024] Example one: such as Figure 1-3 As shown, a vacuum interrupter transfer tray according to an embodiment of the present invention includes a transfer tray base 1, and a cross-shaped guide rod sliding groove 2 is provided on the transfer tray base 1, and the guide The rod sliding groove 2 is slidably connected with a retractable guide rod 3, the transfer disc base 1 is movably connected with an adjustment disc 4, and the adjustment disc 4 is provided with a curve corresponding to the guide rod sliding groove 2 The chute 5, the edge of the adjusting plate 4 is movably connected with an adjusting wheel 6 arranged on the transfer plate base 1, and the adjusting plate 4 is provided with a plurality of upwardly bulging lifting slides 7, and the lifting The slideway 7 is slidably connected to the second adjusting plate 8, and the second adjusting plate 8 is slidably connected with a clamping claw 9 corresponding to the vacuum interrupter, and the clamping claw 9 is fixedly conn...

Embodiment 2

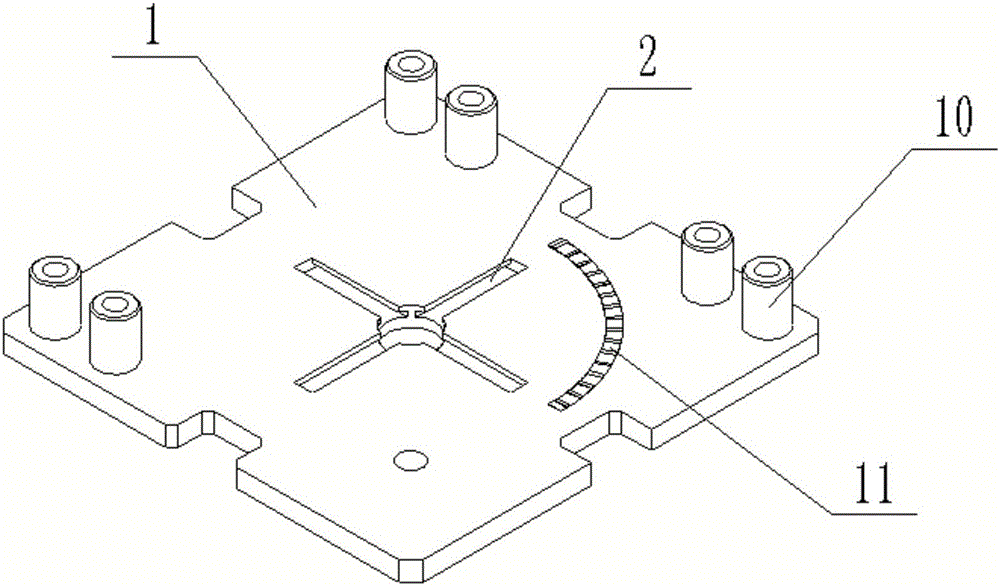

[0030] Embodiment two: such as Figure 4 As shown, a vacuum interrupter transfer tray according to an embodiment of the present invention includes a transfer tray base 1 provided with a detection fixture seat 10 and a cross-shaped guide rod sliding groove 2 And an arc-shaped ruler 11, the guide rod sliding groove 2 is slidably connected with a guide rod 3, and the guide rod 3 is a nylon limit rod for clamping the vacuum interrupter. The transfer tray base 1 is movable An adjustment disc 4 is connected, and the adjustment disc 4 is provided with a curved sliding groove 5 corresponding to the guide rod sliding groove 2, and the adjustment disc 4 is provided with a pointer corresponding to the scale 11.

[0031] In specific use, first rotate the adjustment plate 4, and the adjustment plate 4 drives the curved slide groove 5 to rotate. The curved slide groove 5 pushes the guide rod 3 to move back and forth in the guide rod slide groove 2, thereby controlling the clamping of the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com