A cleaning device and a cleaning method using the same

A cleaning device and cleaning tank technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of increasing cleaning costs, being explosive, reducing cleaning efficiency, etc. Solve the problem of cross-contamination and safety problems, and improve the effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

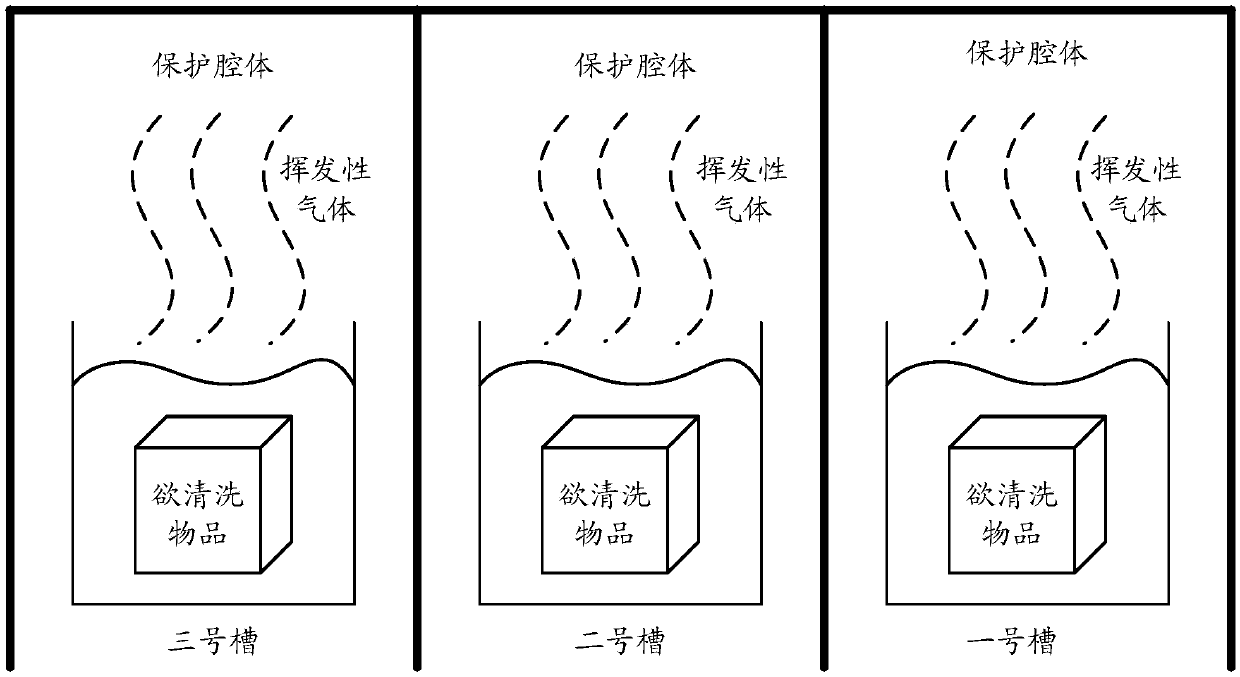

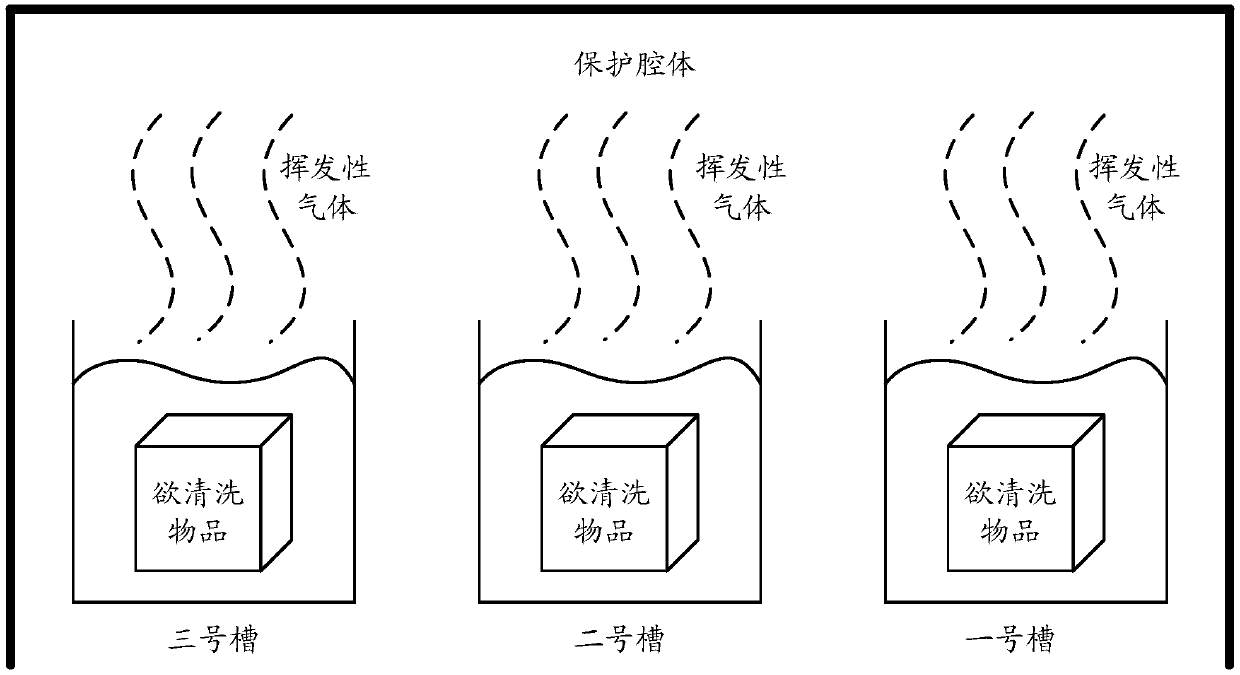

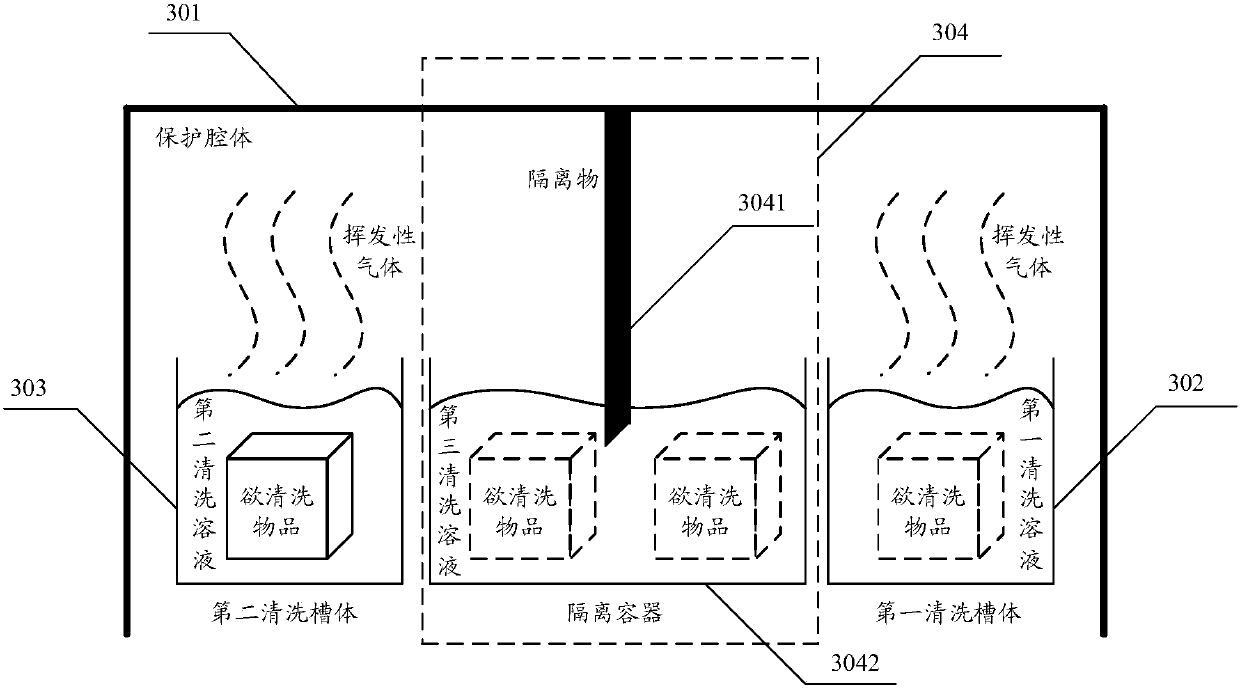

[0037] In the embodiments of the present invention, a cleaning device and a cleaning method using the device will be provided. The cleaning device can solve the problem of mutual cross-contamination and safety problems between cleaning liquids during the cleaning process, and avoid the volatile vapor of the volatile cleaning liquid. Mixed reaction between body and steam; at the same time, it can realize continuous cleaning operation and improve cleaning efficiency. Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0038] In the process of explanation, the solution of the cleaning device will be explained first, then the solution of using the cleaning device for cleaning will be explained, and finally the structure and implementation between the two will be explained.

[0039] image 3 It is a schematic diagram of the structure of the cleaning device, as shown in the figure, including: a protection chamber 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com