Method using attapulgite to prepare particles for removing phosphor from water

A technology of attapulgite and attapulgite, applied in chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc., can solve problems such as inability to drink, achieve the effect of improving adsorption capacity and enhancing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

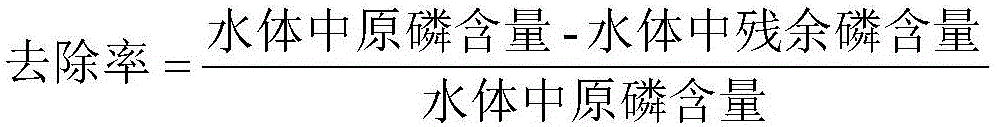

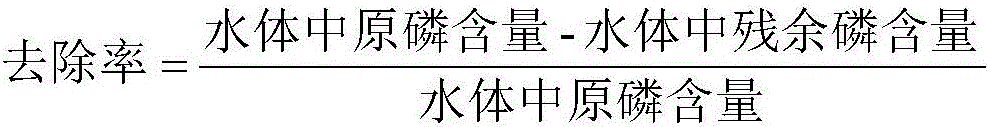

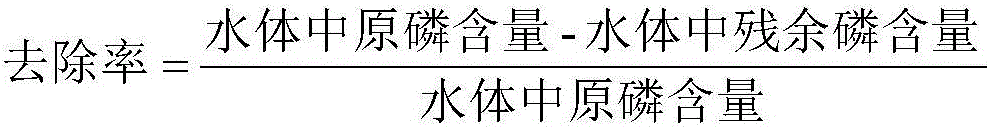

Image

Examples

Embodiment 1

[0020] (1), the attapulgite is crushed to a particle size of 1.05mm to obtain attapulgite particles;

[0021] (2), adding concentrated hydrochloric acid with a concentration of 37% in distilled water is configured into a 5mol / L hydrochloric acid solution, adding the attapulgite particles in the step (1) to acidify the hydrochloric acid solution, the solid-to-liquid ratio is 1:1, mechanically stirring for 6h, The stirring speed is 200r / min to prepare acidified attapulgite particles;

[0022] (3), the acidified attapulgite particles in step (2) were washed 5 times with deionized water, and washed with 1mol / LAgNO 3 The solution was tested for residual Cl ions, and the washed attapulgite particles were vacuum-filtered and placed in an oven at 105°C for 2 hours to obtain dried attapulgite particles;

[0023] (4), cetyltrimethylammonium bromide is added in distilled water to be configured as a cationic surfactant of 1mol / L, and the pH is adjusted to 8.5 with 1mol / L NaoH. The obtai...

Embodiment 2

[0031] (1), the attapulgite is crushed to a particle size of 1.75mm to obtain attapulgite particles;

[0032] (2), adding concentrated hydrochloric acid with a concentration of 37% in distilled water is configured into a 5mol / L hydrochloric acid solution, adding the attapulgite particles in the step (1) to acidify the hydrochloric acid solution, the solid-to-liquid ratio is 1:1, mechanically stirring for 4 hours, The stirring speed is 220r / min to prepare acidified attapulgite particles;

[0033] (3), the acidified attapulgite particles in step (2) were washed 3 times with deionized water, and washed with 1mol / LAgNO 3 The solution was tested for residual Cl ions, and the washed attapulgite particles were vacuum-filtered and placed in an oven at 105°C for 4 hours to obtain dried attapulgite particles;

[0034] (4), cetyltrimethylammonium bromide is added in distilled water to be configured as a cationic surfactant of 0.25mol / L, and the pH is adjusted to 8.5 with 1mol / L NaoH. Un...

Embodiment 3

[0042] (1), the attapulgite is crushed to a particle size of 1.5mm to obtain attapulgite particles;

[0043] (2), adding concentrated hydrochloric acid with a concentration of 37% in distilled water to configure a 5mol / L hydrochloric acid solution, adding the attapulgite particles in the step (1) to acidify the hydrochloric acid solution, the solid-to-liquid ratio is 1:1, mechanically stirring for 5h, The stirring speed is 210r / min to prepare acidified attapulgite particles;

[0044] (3), the acidified attapulgite particles in step (2) were washed 4 times with deionized water, and washed with 1mol / LAgNO 3The solution was tested for residual Cl ions, and the washed attapulgite particles were vacuum-filtered and placed in an oven at 105°C for 3 hours to obtain dried attapulgite particles;

[0045] (4), cetyltrimethylammonium bromide is added in distilled water and is configured into a cationic surfactant of 0.6mol / L, and the pH is adjusted to 8.5 with 1mol / L NaoH, and under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com