Recording layer for optical information recording medium, optical information recording medium, and sputtering target

A recording medium and recording layer technology, which is applied in the field of sputtering targets, can solve problems such as the increase in the number of optical disc layers, the decrease in productivity, and the increase in the number of film layers, and achieve the effect of excellent recording sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] (1) Production of CD

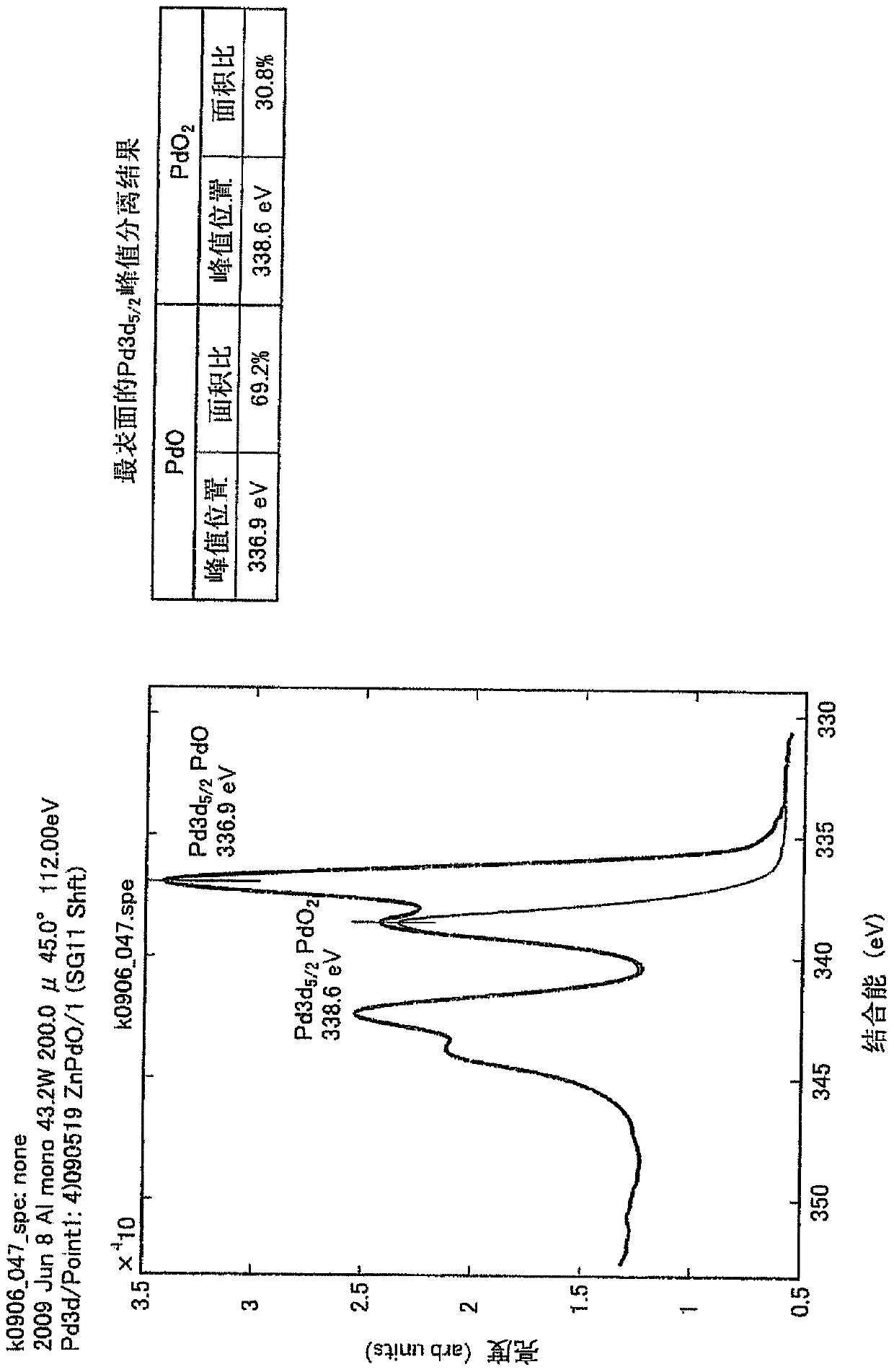

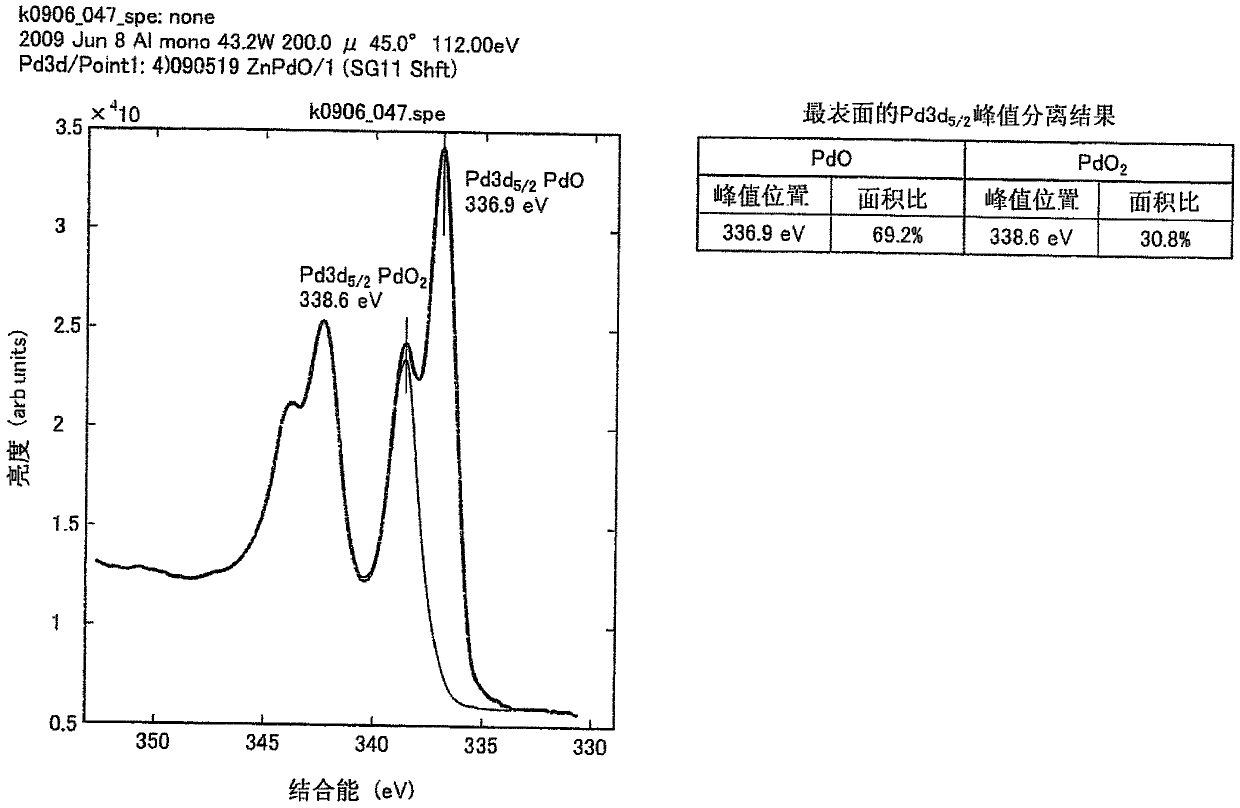

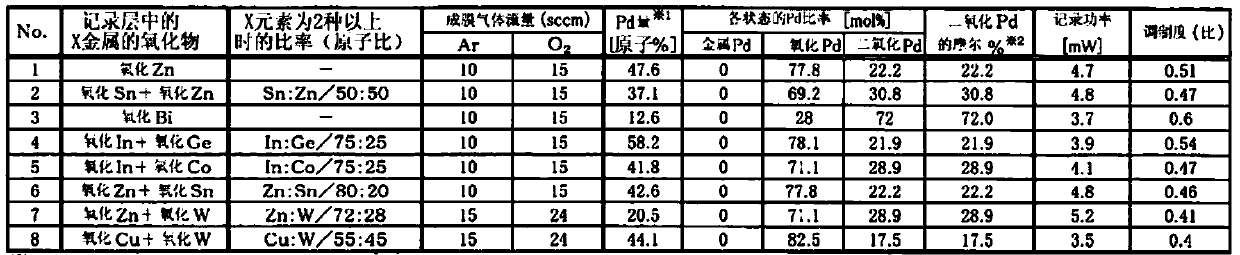

[0106] As the disk substrate, a polycarbonate substrate (thickness: 1.1 mm, diameter: 120 mm, track pitch: 0.32 μm, groove depth: 25 nm) was used. On this substrate, the oxidation of X metal was formed by the DC magnetron sputtering method. Recording layers with different content of Pd oxide and Pd oxide (Pd monoxide and Pd dioxide respectively account for the total mole ratio of Pd monoxide and Pd dioxide, respectively, as shown in Table 1). The film thickness of the recording layer is 40 nm. Regarding sputtering, multiple sputtering under simultaneous discharge of multiple targets of pure X metal (Sn, Zn, Bi, In, Ge, Co, W, Cu) target and pure Pd metal target was performed. The sputtering conditions for forming the above-mentioned recording layer are Ar flow rate: 10 sccm or 15 sccm and oxygen flow rate: 15 sccm or 24 sccm. In addition, air pressure: 0.3 to 0.6 Pa, DC sputtering power: 100 to 200 W, and substrate temperature: room temperature.

[...

Embodiment 2

[0120] (1) Production of CD

[0121] As the disk substrate, a polycarbonate substrate (thickness: 1.1 mm, diameter: 120 mm, track pitch: 0.32 μm, groove depth: 25 nm) was used. In addition, for Nos. 4 to 10, by the DC magnetron sputtering method, an oxide target or a pure metal target was used to form a dielectric layer with the composition and film thickness shown in Table 2 (bottom). The sputtering conditions used to form the dielectric layer (bottom) are Ar flow rate: 10-30 sccm, oxygen flow rate (when a pure metal target is used as a target): 0-10 sccm, air pressure: 0.2 to 0.4 Pa, DC sputtering power: 100~400W, substrate temperature: room temperature.

[0122] Next, a recording layer was formed. In detail, recording layers were respectively formed on the substrate [on the dielectric layer (lower) for Nos. 4 to 10] by the DC magnetron sputtering method. The film thickness of the recording layer is 40 nm. Regarding sputtering, multi-element sputtering under simultaneous disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com