Sealing method for impermeability test of concrete

A technology of impermeability test and concrete, which is applied in the preparation of test samples, permeability/surface area analysis, suspension and porous material analysis, etc. It can solve the problem of concrete impermeability test research affecting concrete durability research and mold testing. Cleaning, poor sealing and other problems, to achieve the effect of strong adhesion, low cost and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Such as figure 1 , Figure 2a , 2b , 2c, Figure 3a , 3b , 3c, Figure 4a , 4b , Shown in 4c, the concrete impermeability test sealing method of the present embodiment, this method comprises the following steps:

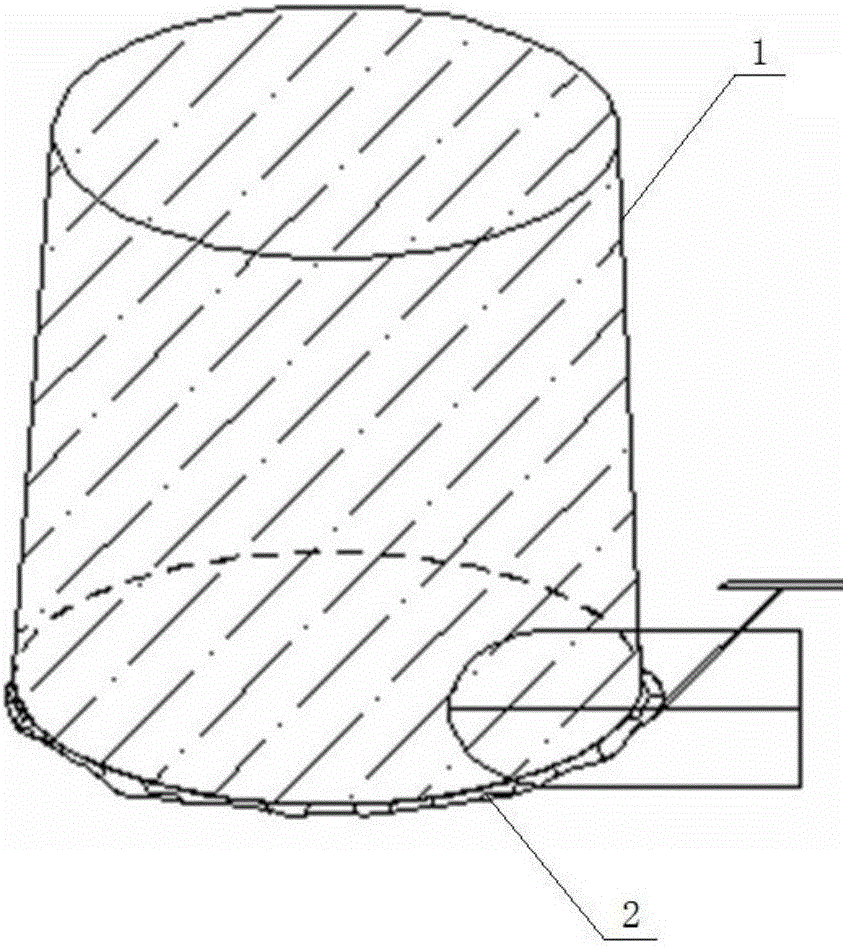

[0035] The first step is to take out the conical frustum test block 1 that needs to be used for the impermeability test until 1 day before the impermeability test, wipe the side of the conical frustum clean and remove the burr 2;

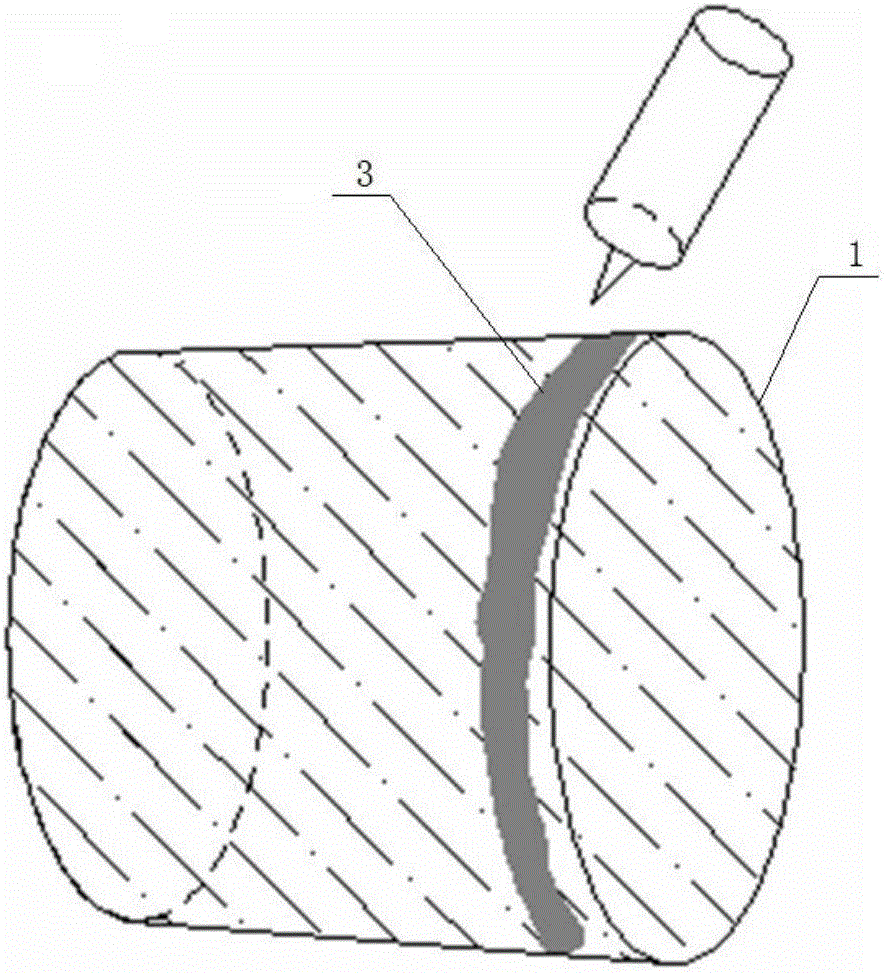

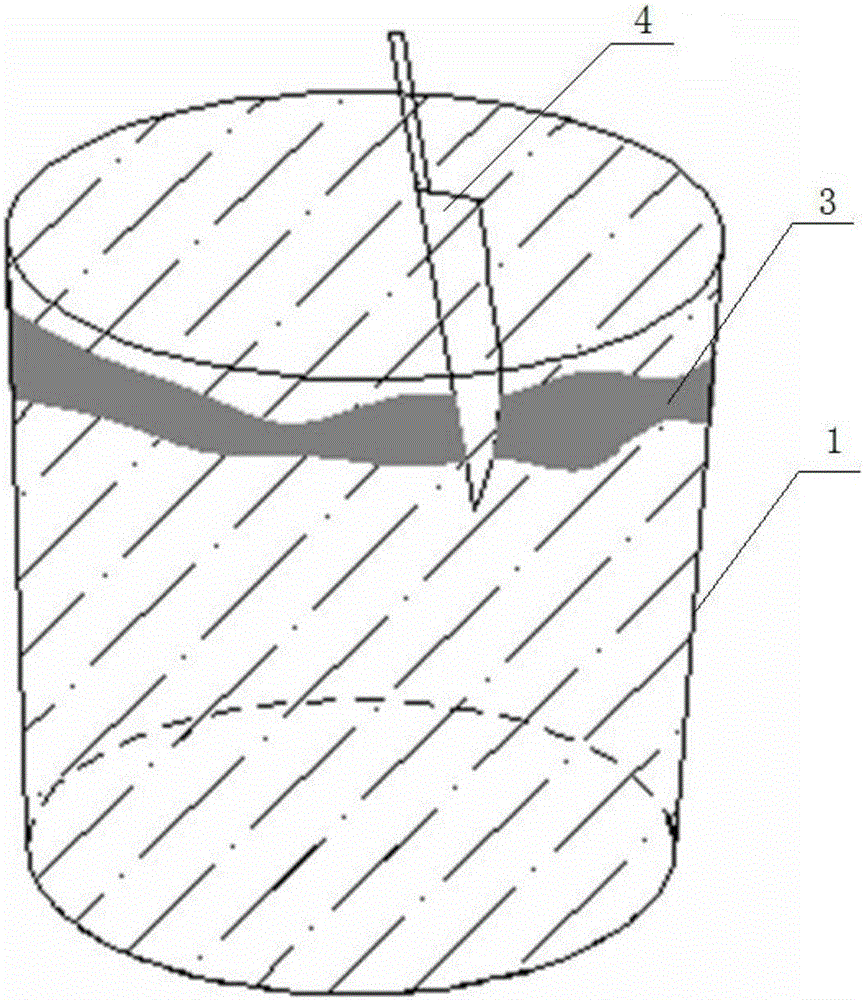

[0036] In the second step, the neutral silicone weather-resistant adhesive 3 is evenly sprayed on the upper end of the side of the conical body, and the upper end of the side of the conical body of the test block is smeared with a scraper 4 to form an annular sealing strip 5, the annular sealing strip 5 Width a is any value in 20mm, 22mm, 25mm or 20-25mm;

[0037] The thickness of the annular sealing strip 5 is any value in 0.3mm, 0.4mm, 0.5mm, 0.6mm or 0.3-0.6mm;

[0038] The third step is to wipe the test block cover clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com