Bouncing detector for end-surface counter bore of bevel gear

A bevel gear and end face technology is applied in the field of bevel gear end face countersunk hole runout inspection tools, which can solve problems such as narrow measurement space, and achieve the effects of simple positioning structure, convenient detection and accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In the following, the present invention will be further explained based on the drawings and the embodiments.

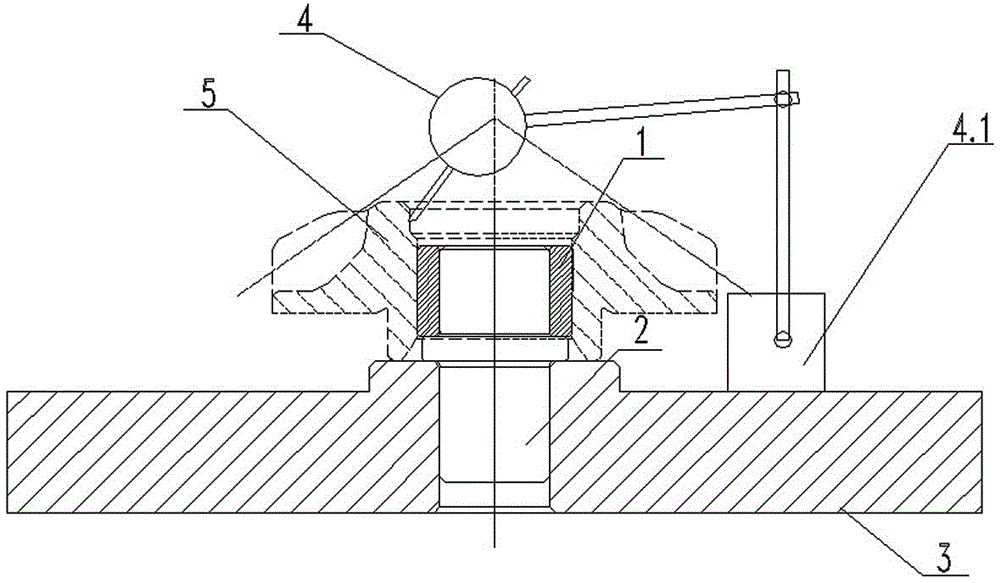

[0013] figure 1 The bevel gear end face counterbore runout checker shown is composed of bushing 1, mandrel 2, base 3 and dial indicator 4. The base 3 is a flat plate with a through hole perpendicular to the upper plane in the center, and the through hole is used for positioning and installing the mandrel 2. The mandrel 2 is a multi-segment cylindrical shaft with a shoulder in the middle section. The lower section of the shaft is positioned and installed in the through hole of the base 3. The middle shoulder is used for axial limit, leaving an upward facing one. The segment shaft is used to locate and install the bushing 1. The bushing 1 is a thin-walled round bushing, which is positioned and installed on a section of the mandrel 2 facing upwards, and the mating length of the two does not exceed the length of the shaft hole of the bevel gear 5 to be inspected. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com