Uniform drying device

A drying device and uniform technology, applied in the direction of drying gas arrangement, heating device, granular material drying, etc., can solve the problems of low drying efficiency and uneven heating of plastic particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

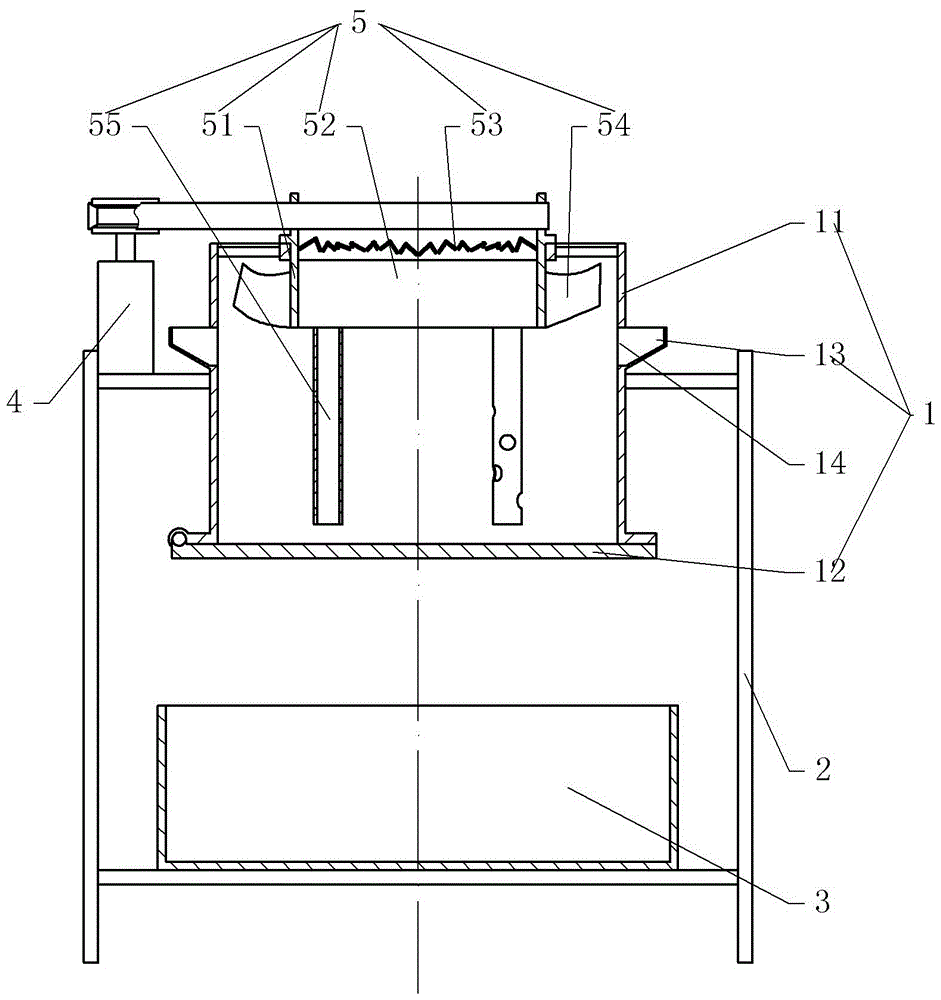

[0019] Such as figure 1 As shown: the uniform drying device includes a drying box 1, a support frame 2, a material receiving box 3 and a hot air device 5; the drying box 1 includes a box body 11 with upper and lower openings and a discharge end cover 12 matched with the lower end of the box body 11, A feeding port 14 is provided on the side of the upper end of the casing 11, and a feeding hopper 13 is also welded at the feeding port 14. When feeding into the drying box 1, the feeding hopper 13 has a guiding effect on the plastic particles, so that the plastic particles Enter into the drying box 1; the lower end of the box body 11 is also welded with a flange, and the discharge end cover 12 has a hinge point, which is hinged with the lower end of the box body 11, so that the discharge end cover 12 can be moved along the The box body 11 rotates, and the discharge end cover 12 can also be fixed on the flange plate at the lower end of the box body 11 by bolts, so that plastic part...

Embodiment 2

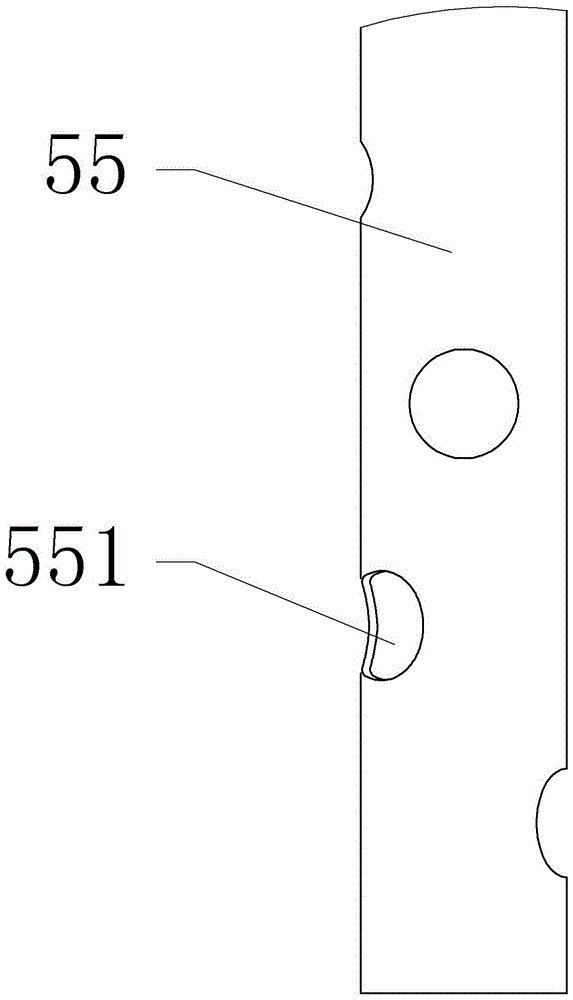

[0024] Such as image 3 As shown, the difference between the second embodiment and the first embodiment is only that the lower end surface of the air supply pipe 55 in the second embodiment is not provided with an opening, and the heat dissipation port 551 at the lower end of the side wall of the air supply pipe 55 is welded with a barbed wire 552, and the barbed wire The aperture of 552 is 5mm, in order to avoid plastic particle to enter in the air supply pipe 55.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com