A multi-stage series displacement heat exchange system

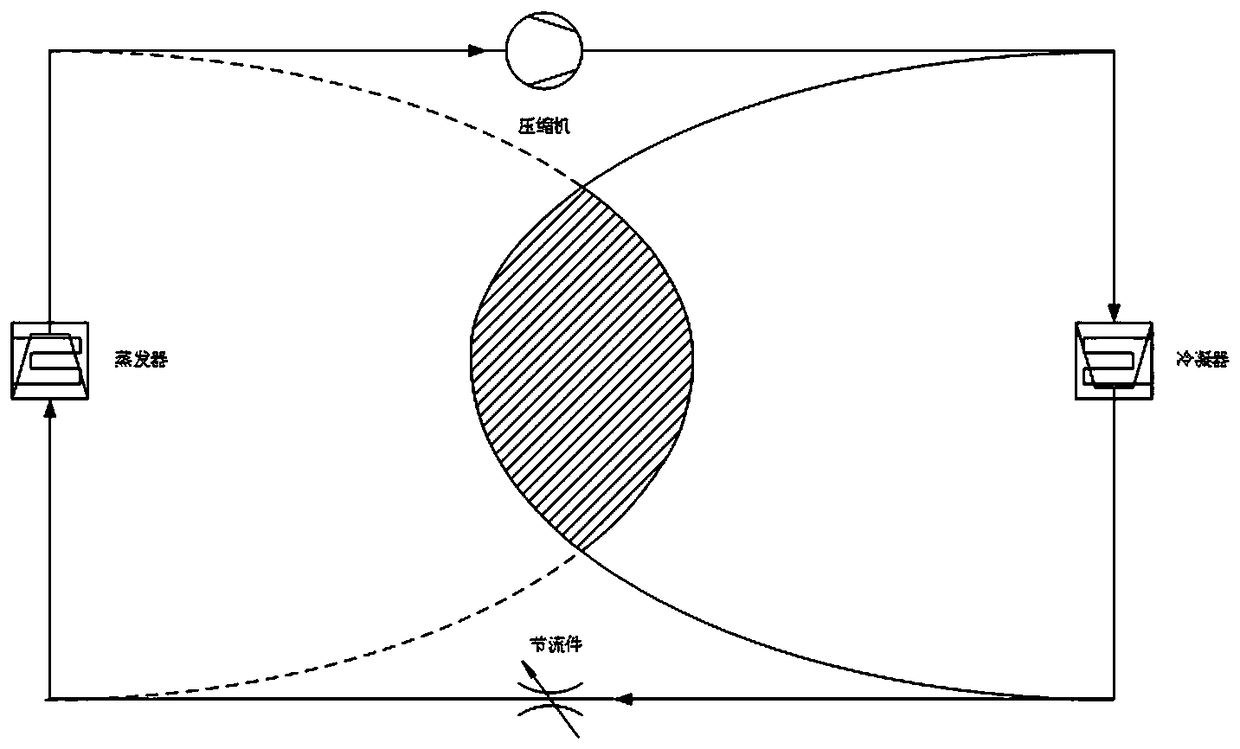

A technology of heat exchange system and heat exchange plate, which is applied in the field of heat exchange, can solve the problem that the evaporator cannot start working, etc., and achieve the effect of increasing temperature difference, reducing pressure difference, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

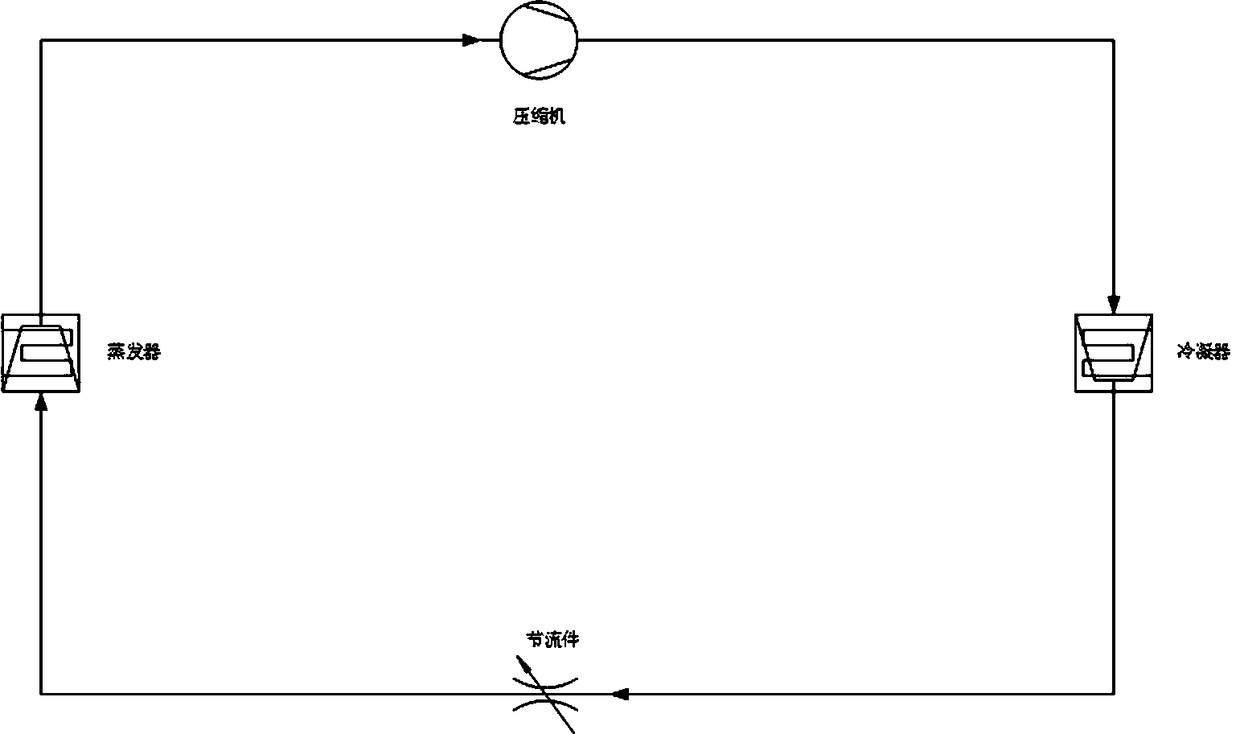

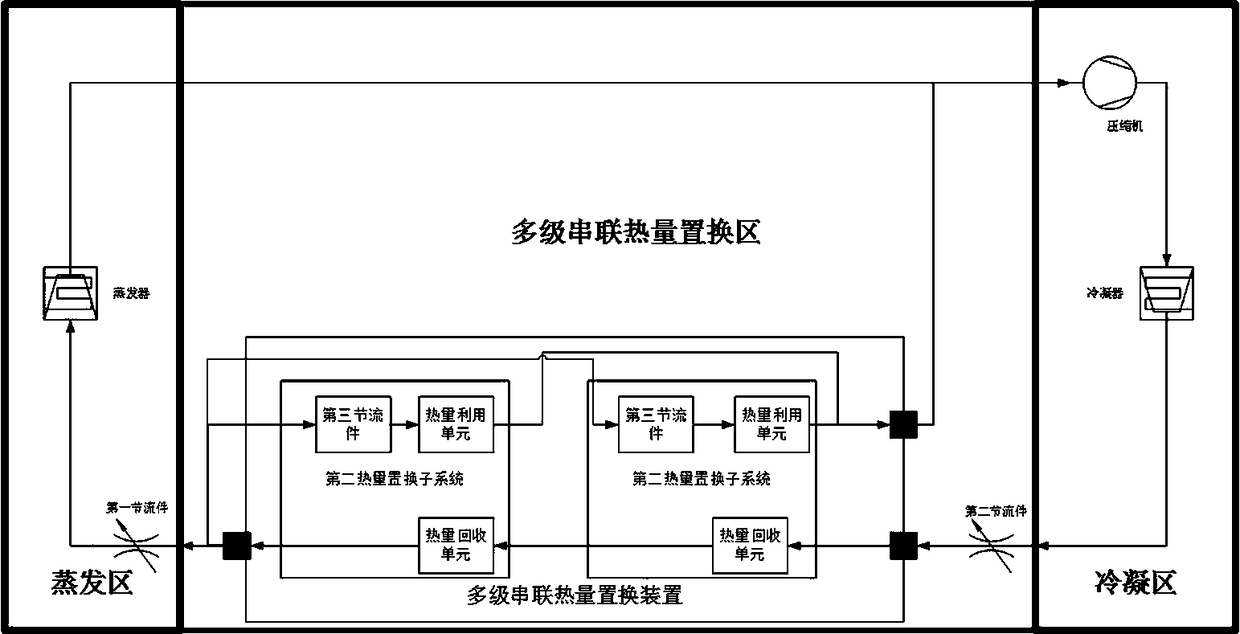

[0040] Such as Figure 4 It is a multi-stage series displacement heat exchange system, which includes a compressor, a condenser, an evaporator, a first throttling piece, a second throttling piece, and a multistage series heat displacement device connected through a working medium flow channel. The outlet of the compressor is connected to the inlet of the condenser, the outlet of the condenser is connected to the inlet of the second throttling member, the outlet of the second throttling member is connected to the inlet of the multi-stage series heat replacement device, and the first outlet of the multi-stage series heat replacement device The inlet of the first throttle is connected, the outlet of the first throttle is connected with the inlet of the evaporator, and the outlet of the evaporator is connected with the inlet of the compressor. Place the condenser in a closed environment such as a room that needs to be heated, and place the evaporator outside the closed environment...

Embodiment 2

[0049] Such as Figure 5 It is a multi-stage series displacement heat exchange system, which includes a compressor, a condenser, an evaporator, a first throttling piece, a second throttling piece, and a multistage series heat displacement device connected through a working medium flow channel. Among them, the evaporator includes an ordinary evaporator and a heat collecting plate (a heteropolymer heat absorbing plate that absorbs heat passively). The outlet of the compressor is connected to the inlet of the condenser, the outlet of the condenser is connected to the inlet of the second throttling member, the outlet of the second throttling member is connected to the inlet of the multi-stage series heat replacement device, and the first outlet of the multi-stage series heat replacement device The inlet of the first throttle is connected, the outlet of the first throttle is connected with the inlet of the evaporator, and the outlet of the evaporator is connected with the inlet of ...

Embodiment 3

[0053] Such as Figure 6 It is a multi-stage series displacement heat exchange system, which includes a compressor, a condenser, an evaporator, a first throttling piece, a second throttling piece, and a multistage series heat displacement device connected through a working medium flow channel. Among them, the evaporator includes an ordinary evaporator and a heat collecting plate (a heteropolymer heat absorbing plate that absorbs heat passively). The outlet of the compressor is connected to the inlet of the condenser, the outlet of the condenser is connected to the inlet of the second throttling member, the outlet of the second throttling member is connected to the inlet of the multi-stage series heat replacement device, and the first outlet of the multi-stage series heat replacement device The inlet of the first throttle is connected, the outlet of the first throttle is connected with the inlet of the evaporator, and the outlet of the evaporator is connected with the inlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com