Heat preservation structure using vacuum insulated panels, and refrigerator

A technology of vacuum insulation panels and refrigerators, applied in the direction of heat preservation, protection of pipelines through heat insulation, application, etc., can solve problems affecting the stability and insulation performance of insulation structures, failure of insulation performance of vacuum insulation panels, damage of barrier film of vacuum insulation panels, etc. , to achieve the effect of improving the reliability of thermal insulation structure and thermal insulation performance, improving reliability and thermal insulation performance reliability, improving performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

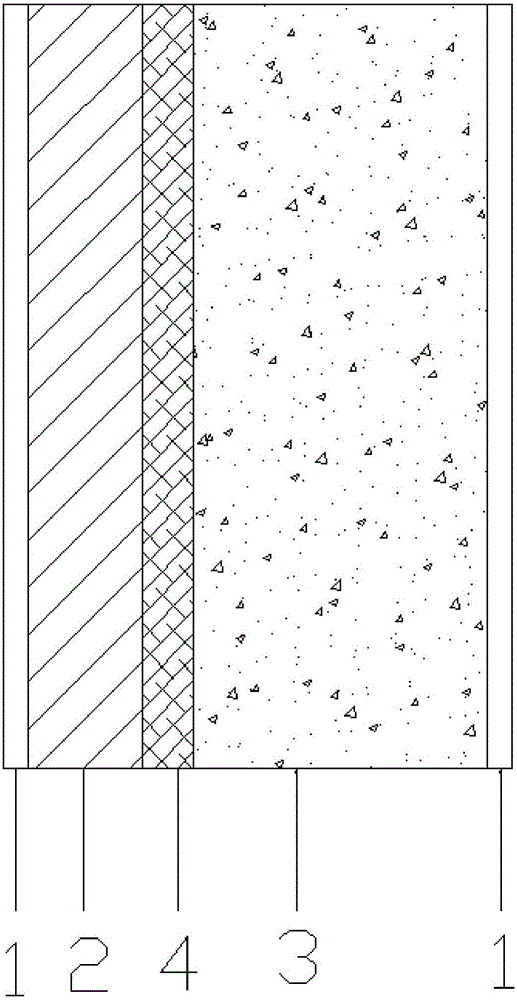

[0031] Such as figure 1 As shown, the first embodiment of the present invention includes two layers of protective layers 1, one layer of vacuum insulation panels 2, one layer of foam insulation layers 3 and one layer of elastic material 4, the above composition is according to the protection layer 1, vacuum insulation panels 2. The elastic material layer 4, the foam insulation layer 3 and the protective layer 1 are pasted and connected in sequence. The elastic material layer 4 is made of natural fiber sheets, and the foamed heat insulating layer 3 is polyurethane foamed plastic. Before installation, the elastic material layer 4 is pasted on one side of the vacuum insulation panel 2 to protect the vacuum insulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com