Low-voltage network electric pole

A low-voltage distribution network and pole technology, applied in the field of low-voltage distribution network poles, can solve problems such as poor bending resistance, easy loosening and falling off, and limited strength, so as to achieve increased tensile strength, ensure safety, and reduce effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

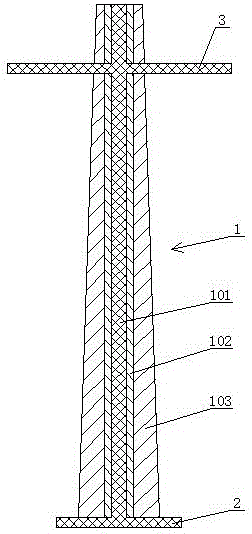

[0023] As shown in the figure, the present invention includes a rod body 1. The rod body 1 includes a supporting stem 101. The outer surface of the supporting stem 101 is provided with a cloth-impregnated resin layer 102. The outer surface of the cloth-impregnated resin layer 102 is provided with a protective layer 103. The resin layer 102 is fiberglass cloth or carbon fiber cloth or glass fiber cloth or non-woven fabric impregnated with resin, and the cloth impregnated with resin layer 102 is tightly wound on the outer surface of the support core 101 after melting. The bottom of the rod body 1 is provided with a base 2 fixedly connected to the supporting stem 101 , and the upper part of the rod body 1 is provided with a wire rack rod 3 fixedly connected to the supporting stem 101 , and the wire rack rod 3 is perpendicular to the supporting stem 101 . The upper and lower ends of the supporting stem 101 are provided with terminals (not shown in the figure) for connecting to ligh...

Embodiment 2

[0034] The difference between this embodiment and Embodiment 1 is that the supporting core 101 column includes the following raw materials in parts by weight: 40 parts of Ti, 40 parts of Al, 5 parts of Cr, 1 part of Mn, 8 parts of tetraacicular zinc oxide whiskers, mixed rare earth 1 serving. The mixed rare earth is composed of yttrium, berkelium and lanthanum, and the mass ratio of the three is 1: (0.20-0.22): (0.30-0.32).

Embodiment 3

[0036] The difference between this embodiment and Embodiment 1 is that the supporting stem 101 includes the following raw materials in parts by weight: 60 parts of Ti, 60 parts of Al, 10 parts of Cr, 3 parts of Mn, 10 parts of tetraacicular zinc oxide whiskers, mixed rare earth 4 parts. The mixed rare earth is composed of yttrium, berkelium and lanthanum, and the mass ratio of the three is 1: (0.20-0.22): (0.30-0.32).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com