Assembling type steel plate bin integration system

An integrated system and steel silo technology, which is applied in the field of assembled steel silo integrated systems, can solve the problems of less land occupation, large storage capacity, and high degree of mechanization, and achieve the effects of saving storage costs, large storage volume, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

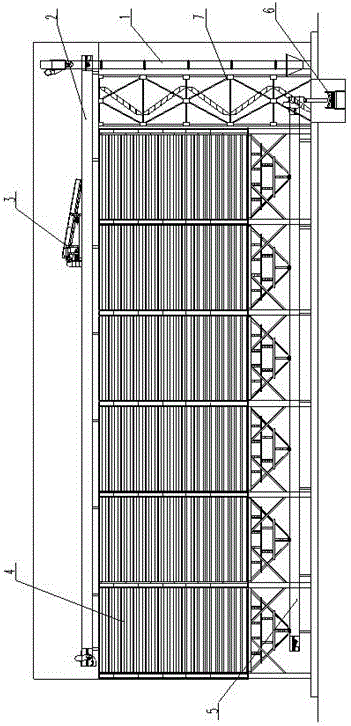

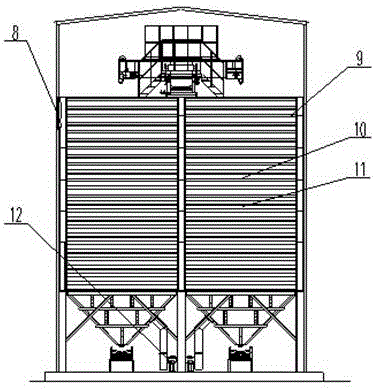

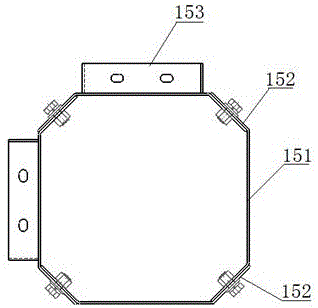

[0030] Such as Figure 1 to Figure 5 A fabricated steel silo integrated system is shown, which includes a silo body 4 and an insulation layer 8. The silo body 4 is assembled from at least two rows of assembled steel plate single warehouses 13, and each row of steel plate single warehouses 13 includes at least one steel plate Single warehouse 13, the top of the steel plate single warehouse 13 is closed and paved with a material inlet and an observation port, and the joints of the tops of two adjacent rows of steel plate single warehouses 13 are laid with a cloth belt conveyor 2, a cloth trolley 3, and a cloth belt The feed end of the conveyor 2 is connected to the discharge end of the elevator 1 arranged on one side of the warehouse body 4; the bottom of each row of steel plate single warehouses 13 is provided with a discharge belt conveyor 5, and the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com