A spiral tube heat exchanger with variable diameter tube winding

A tubular heat exchanger and heat exchanger technology, applied in the direction of heat exchanger types, indirect heat exchangers, fixed tubular conduit components, etc., can solve the problem of not considering the change of fluid density and physical properties, and the inability to mix working fluids under high pressure in the tube The flow condition improves the adjustment, inapplicability and other problems, and achieves the effect of compact structure, efficient heat exchange and reduced quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

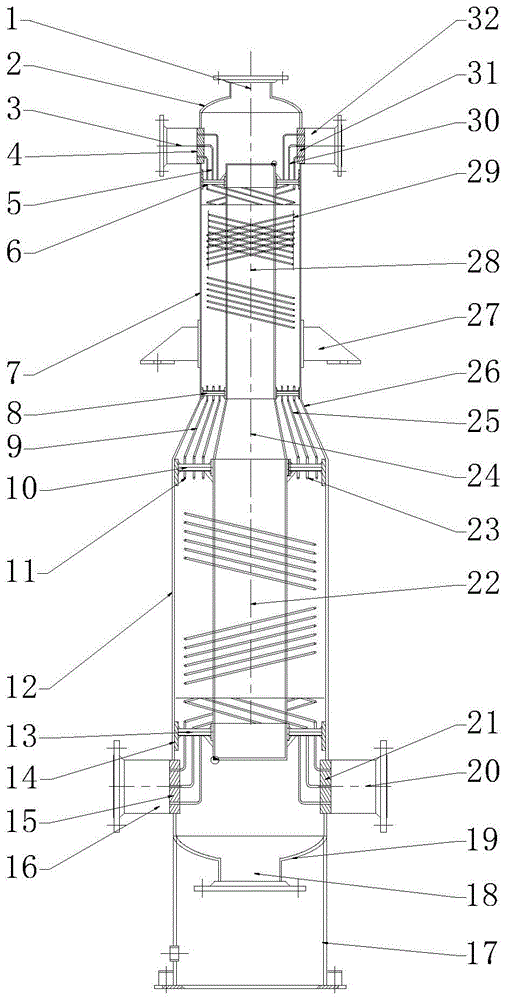

[0026] see figure 1 As shown, the spiral tube heat exchanger with variable diameter tube winding provided by the present invention includes:

[0027] A heat exchanger shell; the heat exchanger shell is composed of a large-diameter shell 12, a transitional-diameter shell 26 and a small-diameter shell 7 connected in sequence;

[0028] The heat exchanger core tube body that is installed in the heat exchanger shell concentrically; the heat exchanger core tube body is composed of a large-diameter core tube body 22, a transition core tube body 24 and a small-diameter core tube body connected in sequence body 28; the large-diameter core body 22, the transition core body 24 and the small-diameter core body 28 are respectively equal to the corresponding large-diameter housing 12, transition-diameter housing 26 and small-diameter housing 7;

[0029] The first fixed flower plate 6 installed between the upper end of the small-diameter core body 28 and the upper end of the small-diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com