Ultrasonic suspension gyroscope based on planar holographic transducer

A transducer and gyroscope technology, which is applied in directions such as rotating gyroscopes, can solve the problems of difficult miniaturization, difficult wide application, and complex structure, and achieve the effects of improving gyro precision, low cost, and avoiding interfering torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

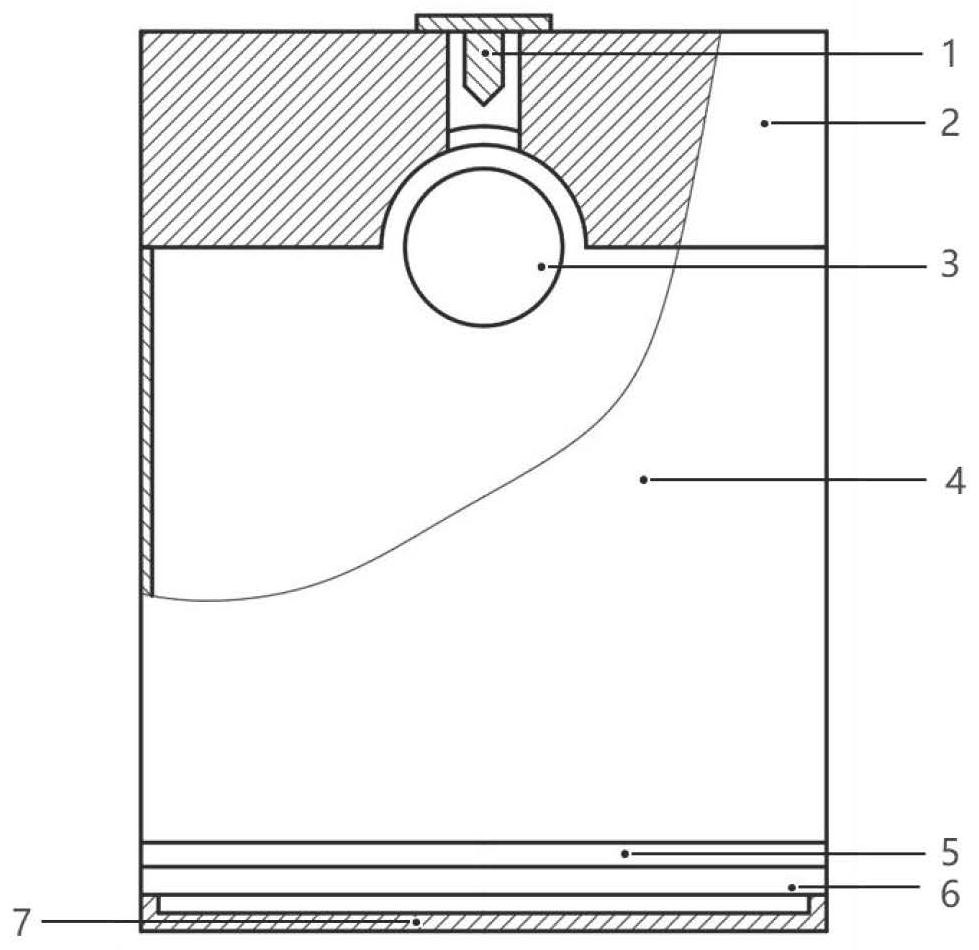

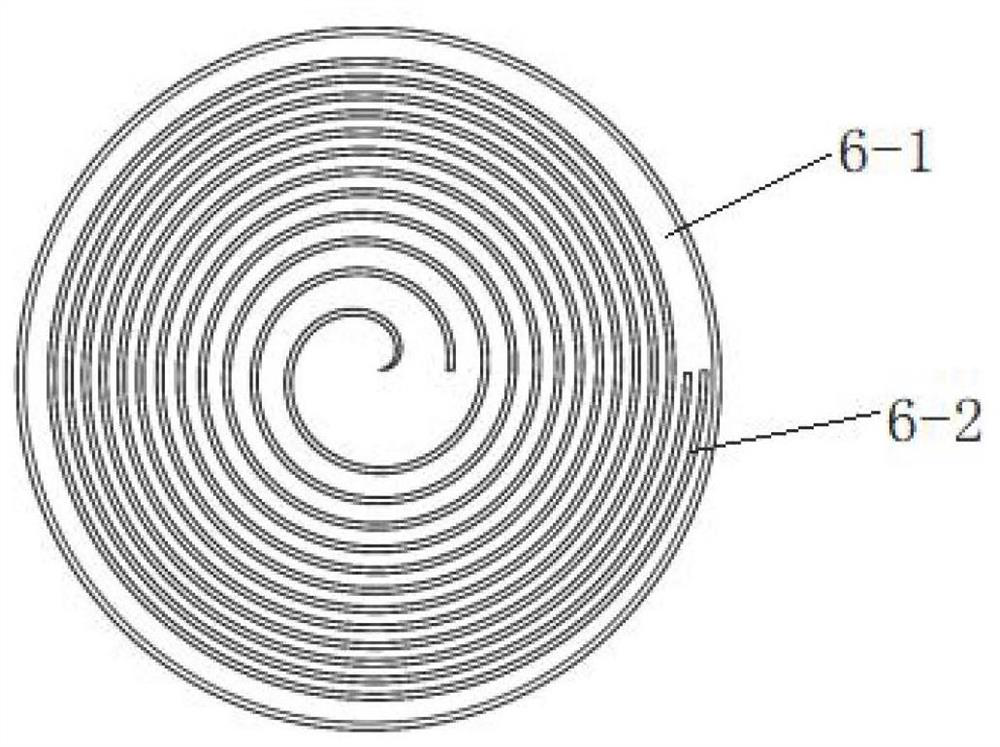

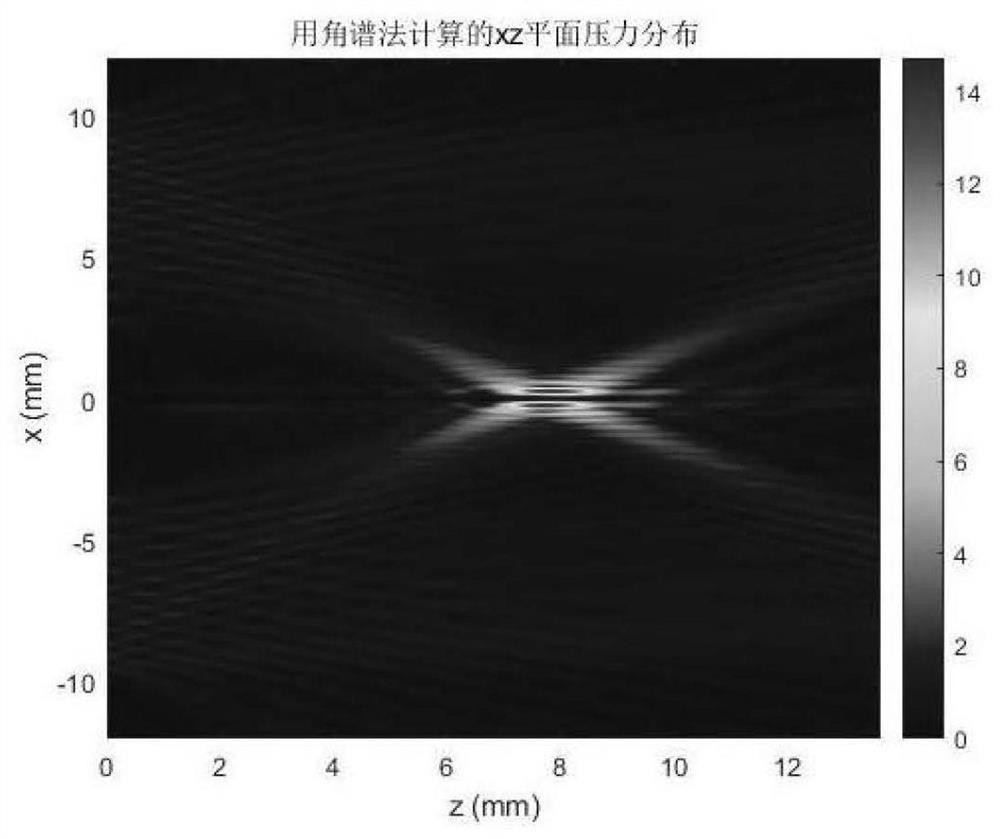

[0038] Such as figure 1 with figure 2 As shown, an ultrasonic suspension gyroscope based on a planar holographic transducer includes a photoelectric detection device 1, which is vertically installed in the mounting hole of the magnetic field adding and rotating system 2, and the axis of the photoelectric detection device 1 is directly facing the spherical shape The spherical center of the hollow rotor 3 obtains an angle signal by aiming at the engraved line on the spherical hollow rotor 3 with the help of the photoelectric detection device 1. The photoelectric sensing technology is used to detect non-electrical quantities, and has the advantages of simple structure, non-contact, high reliability, The characteristics of high precision and fast response can meet the technical requirements of the ultrasonic gyroscope angle measurement system; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com