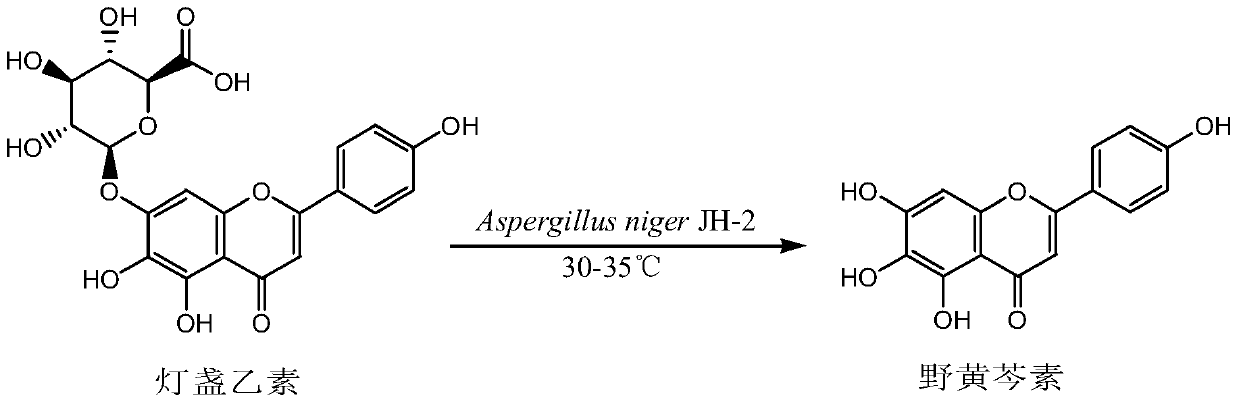

A kind of method for preparing scutellarein by biotransforming scutellarin

A technology of scutellarin and scutellarein, applied in biochemical equipment and methods, methods based on microorganisms, microorganisms, etc., can solve the problems of low conversion yield, poor specificity, and few by-products, and achieve high conversion efficiency , Strong anti-pollution ability and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The selection of embodiment 1 transformation strain

[0020] For the 3 strains of Aspergillus niger in the laboratory, including Aspergillus niger XW-2 (preservation number CCTCC No: M 2011358), Aspergillus niger MJ (preservation number CCTCC NO: M 2013329) and niger Aspergillus JH-2 (Deposit No. CCTCC No: M2014398), and 5 Aspergillus niger strains screened from soil, including Aspergillus niger ZC03, ZC04, ZC08, ZC11 and ZC14 strains. First pick a full cyclospore from the above-mentioned Aspergillus niger slant strain stored in a refrigerator at 4°C, inoculate it in a fresh slant medium, and cultivate the slant in a biochemical incubator at 28°C for 3 days to obtain activated Aspergillus niger slant. Dip the spores from the slant of the activated strains with a cotton swab, inoculate them into 50 mL of enzyme-producing medium, and cultivate them with shaking at 28 °C and 200 r / min for 3 days (the dry cell concentration of the culture solution of different strains is ...

Embodiment 2

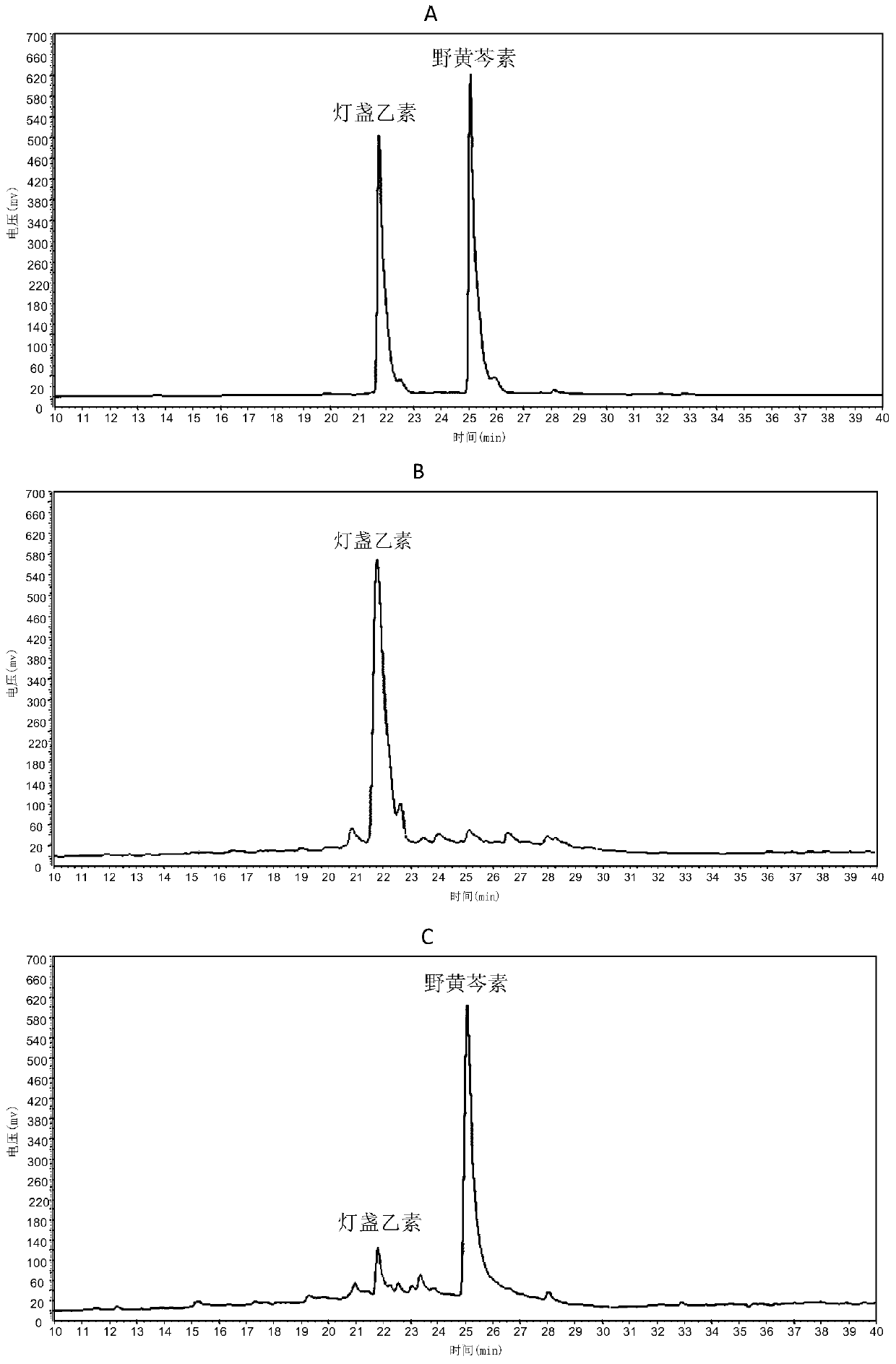

[0031] Embodiment 2: verification of transformation stability of Aspergillus niger JH-2

[0032] Using Aspergillus niger JH-2 as the enzyme-producing strain, under the fermentation scale of 50mL shake flask, the step of seed expansion cultivation was added, and the crude enzyme solution was fermented to transform scutellarin, and the transformation stability of the strain was verified. The specific process steps were as follows:

[0033] (1) The aspergillus niger JH-2 slant bacterial classification preserved in 4 ℃ of refrigerators is inoculated in fresh PDA slant medium, and slant is cultivated at 30 ℃ of constant temperature for 2 days, and described PDA slant medium composition and preparation method are the same as embodiment 1 ;

[0034] (2) Use a cotton swab to dip the spores of Aspergillus niger JH-2 after activation in step (1) into 50mL seed culture medium twice, and cultivate them at 30°C and 200r / min constant temperature shaking conditions for 2 days to obtain a dry...

Embodiment 3

[0038] Embodiment 3: preferred conversion process

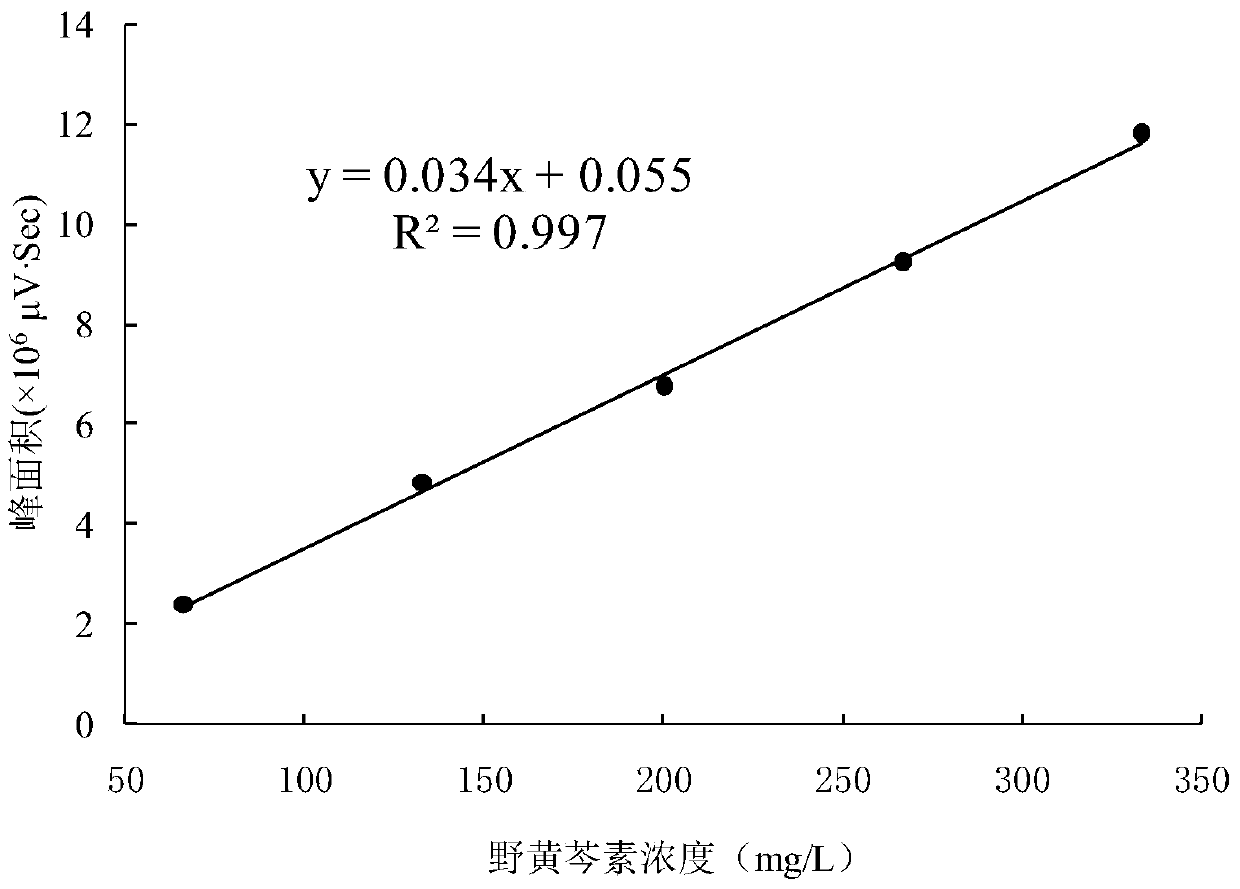

[0039] On the basis of Example 2, the composition of the enzyme-producing medium, fermentation and culture conditions, conversion substrate concentration, and conversion time were optimized. Aspergillus niger JH-2 was fermented to prepare the crude enzyme solution for the conversion of scutellarin, and the conversion of scutellarein was obtained rate increased significantly. The preferred biotransformation method prepares the processing steps of scutellarein as follows:

[0040] (1) Inoculate the Aspergillus niger JH-2 slant bacterial classification preserved in 4 DEG C of refrigerators on fresh slant medium, and culture the slant at a constant temperature of 30 DEG C for 2 days, and the composition and preparation method of the slant medium are the same as in Example 1;

[0041] (2) Use a cotton swab to dip the spores of Aspergillus niger JH-2 after activation in step (1) into 50mL seed medium for 2 times, and cultivate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com