Full-automatic steamer filling system based on flexible sprinkling robot

A robotic and fully automatic technology, applied in the field of fully automatic retort system and brewing equipment, can solve the problems of feeding metering, poor speed and continuity, strong dependence on manual experience, affecting the effect of steaming wine, etc., so as to improve the processing quality, Ensure safety, stability, hygiene, and good distillation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

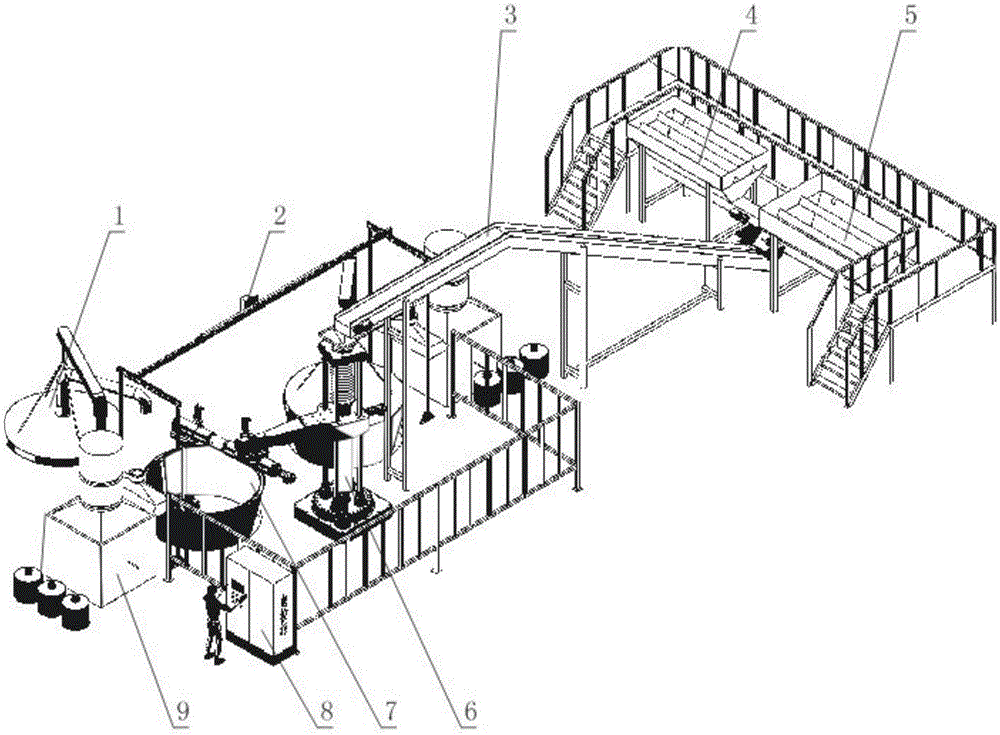

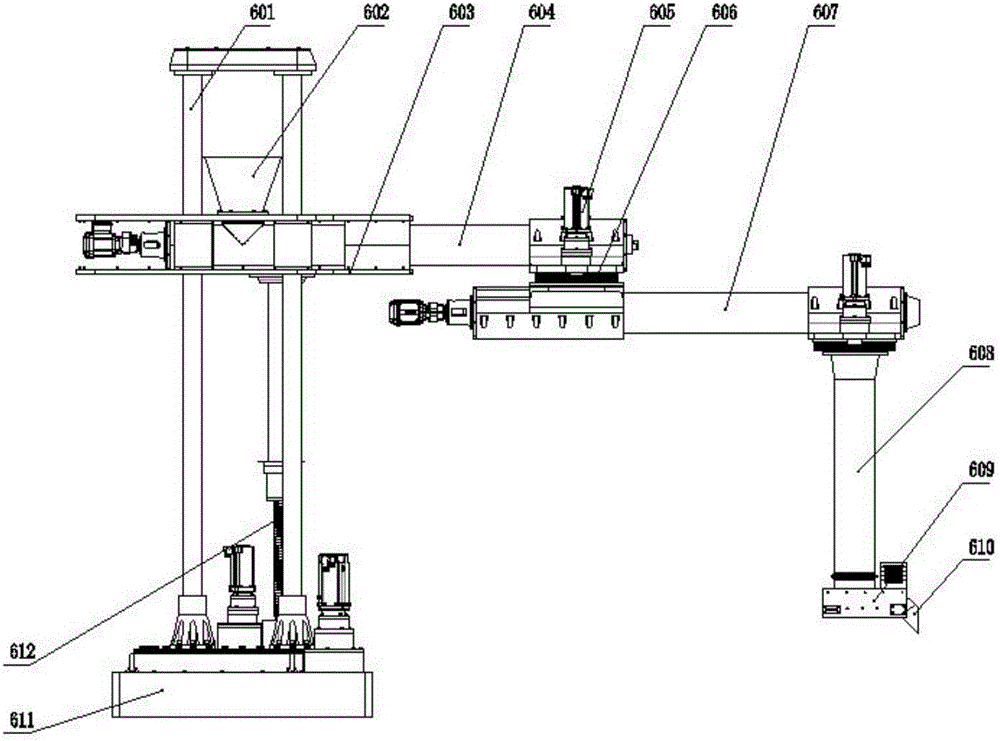

[0044]A fully automatic retort system based on a flexible material spreading robot, including wheat skin conveyor 4, wine grains conveyor 5, wine grains lifting conveyor belt 3, flexible material spreading robot 6, screening bucket 7, infrared camera 2, and bucket cover The hoisting device 1, the condenser 9 and the electric control cabinet 8, the outlets of the wheat bran conveyor and the wine grains conveyor are all connected to the inlet of the wine grains lifting conveyor belt, and the outlet of the wine grains lifting conveyor belt is connected to a flexible The feeding hopper of the material spreading robot 6; two screening barrels 3 are installed at intervals in the working area of the flexib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com