Hole plate mixed spiral flow pipeline energy dissipating device

A technology of mixing screw and energy dissipation device, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of affecting water flow, small adjustment range, inconvenient operation, etc., to increase the adjustment range, adjust The effect of large range and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

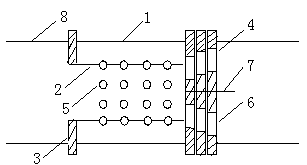

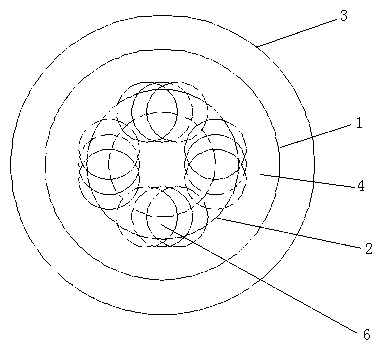

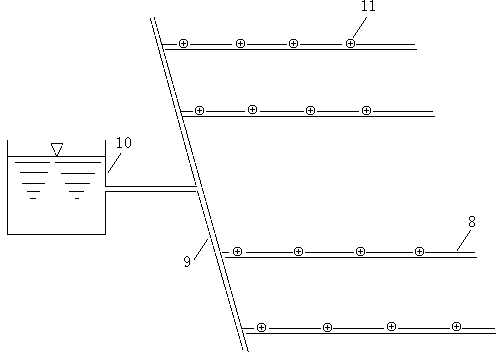

[0023] Implementation mode 1: Such as figure 1 As shown, in the water pipeline, the outer pipe 1, the inner pipe 2 and the water delivery branch pipe 8 are connected through the flange 3, and the outer pipe 1, the inner pipe 2 and the water delivery branch pipe 8 are kept concentric, and the diameter of the outer pipe 1 is the same as that of the water delivery pipe The branch pipes 8 are the same, and the oblique round holes 5 are arranged symmetrically and evenly at a certain inclination angle around the inner pipe 2 like a screen. If the ratio of the total area of the oblique circular holes 5 to the cross-sectional area of the outer pipe 1 is 80%, each orifice 4 is connected by a rotating shaft 7, and the rotating shaft 7 coincides with the central axis of the water delivery branch pipe 8, and each orifice 4 Along the axial direction of the water delivery branch pipe 8, the perfect circular holes 6 are arranged like a screen, and the ratio of the total area of the ...

Embodiment approach 2

[0025] Implementation mode 2: Such as figure 1 As shown, in the water pipeline, the outer pipe 1, the inner pipe 2 and the water delivery branch pipe 8 are connected through the flange 3, and the outer pipe 1, the inner pipe 2 and the water delivery branch pipe 8 are kept concentric, and the diameter of the outer pipe 1 is the same as that of the water delivery pipe The branch pipes 8 are the same, and the oblique square holes 5 are symmetrically and evenly arranged around the inner pipe 2 like a screen according to a certain inclination angle. Assuming that the ratio of the total area of the oblique square hole 5 to the cross-sectional area of the outer pipe 1 is 45%, each orifice plate 4 is connected by a rotating shaft 7, and the rotating shaft 7 coincides with the central axis of the water delivery branch pipe 8, and each orifice plate 4 Along the axial direction of the water delivery branch pipe 8, the square holes 6 are arranged like a screen, and the ratio of the...

Embodiment approach 3

[0027] Implementation mode 3: Such as figure 1As shown, in the water pipeline, the outer pipe 1, the inner pipe 2 and the water delivery branch pipe 8 are connected through the flange 3, and the outer pipe 1, the inner pipe 2 and the water delivery branch pipe 8 are kept concentric, and the diameter of the outer pipe 1 is the same as that of the water delivery pipe The branch pipe 8 is the same, and the oblique spiral holes 5 are arranged symmetrically and evenly at a certain inclination angle around the inner pipe 2 like a screen. Assuming that the ratio of the total area of the oblique spiral holes 5 to the cross-sectional area of the outer pipe 1 is 10%, the positive spiral holes 6 are arranged on the orifice plate 4 along the axial direction of the water delivery branch pipe 8 like a screen, and the positive spiral holes 6 are arranged on the orifice plate 4. The ratio of the total area of the holes 6 to the cross-sectional area of the outer tube 1 is 10%. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com