A soil conditioner for improving the fertility of saline-alkali land and its application

A soil improver and saline-alkali land technology, applied in the fields of application, soil conditioning materials, organic fertilizers, etc., can solve the problems of secondary pollution costs of soil and crops, achieve the effects of reducing secondary pollution, realizing recycling, and increasing nitrogen fixation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A soil improver for improving the fertility of saline-alkali land, said soil improver is prepared by the following method:

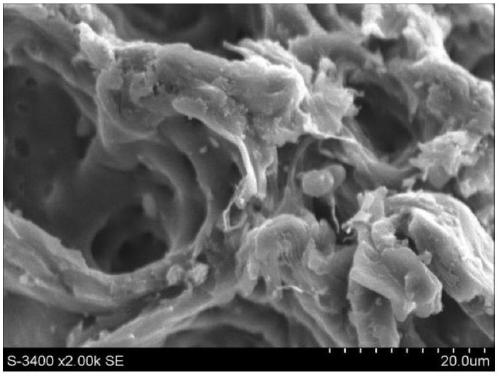

[0037] Step 1. The activated sludge is naturally air-dried first, then pulverized by a sealed sample preparation grinder, and finally passed through a 100-mesh sieve and the activated sludge powder under the sieve is collected;

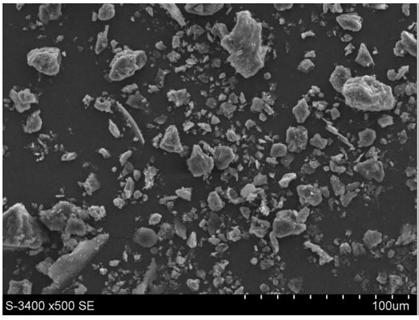

[0038] Step 2. The corn cob is first washed with deionized water, then air-dried naturally, then crushed by a high-speed universal grinder, and finally passed through a 10-mesh sieve to collect the corn cob powder under the sieve;

[0039]Step 3. After mixing 2.86g of activated sludge powder and 7.14g of corn cob powder evenly, put them into a tubular electric furnace with nitrogen, set the nitrogen rate to 300mL / min, and the heating rate to 15°C / min. Pyrolyze at a pyrolysis temperature of 325° C. for 3 hours, and cool to obtain the soil conditioner.

[0040] The pyrolysis temperature in step 3 of this implementation is ...

Embodiment 2

[0049] A soil improver for improving the fertility of saline-alkali land, said soil improver is prepared by the following method:

[0050] Step 1. The activated sludge is naturally air-dried first, then pulverized by a sealed sample preparation grinder, and finally passed through a 100-mesh sieve and the activated sludge powder under the sieve is collected;

[0051] Step 2. The corn cob is first washed with deionized water, then air-dried naturally, then crushed by a high-speed universal grinder, and finally passed through a 10-mesh sieve to collect the corn cob powder under the sieve;

[0052] Step 3. After mixing 2.86g of activated sludge powder and 7.14g of corn cob powder evenly, put them into a tubular electric furnace with nitrogen, set the nitrogen rate to 300mL / min, and the heating rate to 15°C / min. Pyrolyze at a pyrolysis temperature of 325° C. for 0.5 h, and cool to obtain the soil conditioner.

[0053] The pyrolysis time in step 3 of this implementation is 0.5h, an...

Embodiment 3

[0059] A soil improver for improving the fertility of saline-alkali land, said soil improver is prepared by the following method:

[0060] Step 1. The activated sludge is naturally air-dried first, then pulverized by a sealed sample preparation grinder, and finally passed through a 100-mesh sieve and the activated sludge powder under the sieve is collected;

[0061] Step 2. The corn cob is first washed with deionized water, then air-dried naturally, then crushed by a high-speed universal grinder, and finally passed through a 10-mesh sieve to collect the corn cob powder under the sieve;

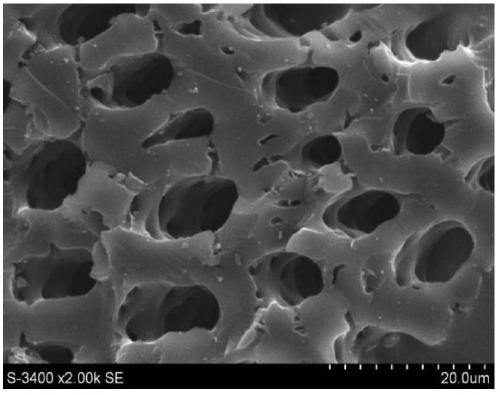

[0062] Step 3. After mixing 1.67g of activated sludge powder and 8.33g of corn cob powder evenly, put it into a tubular electric furnace with nitrogen, set the nitrogen rate to 300mL / min, and the heating rate to 15°C / min. Pyrolysis at a pyrolysis temperature of 450° C. for 3 hours, and cooling to obtain the soil conditioner.

[0063] The mass ratio of activated sludge powder and corn cob powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com