Solid-liquid separation mechanism capable of adjusting effluent flow rate and sludge concentration and using method thereof

A sludge concentration, solid-liquid separation technology, applied in chemical instruments and methods, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Reduce the motor speed and other problems to improve the dehydration efficiency, enhance the filtration effect, and increase the sludge concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Preparation of medicament: mix polyacrylamide with water to prepare a medicament with a mass fraction of 1‰;

[0029] 2) Feeding and dosing: the sludge to be treated is passed into the mixing flocculation tank 1 through the feeding port 101, and the above-mentioned chemical is passed into the mixing flocculation tank 1 through the dosing port 102, and the sludge and the chemical are mixed with each other;

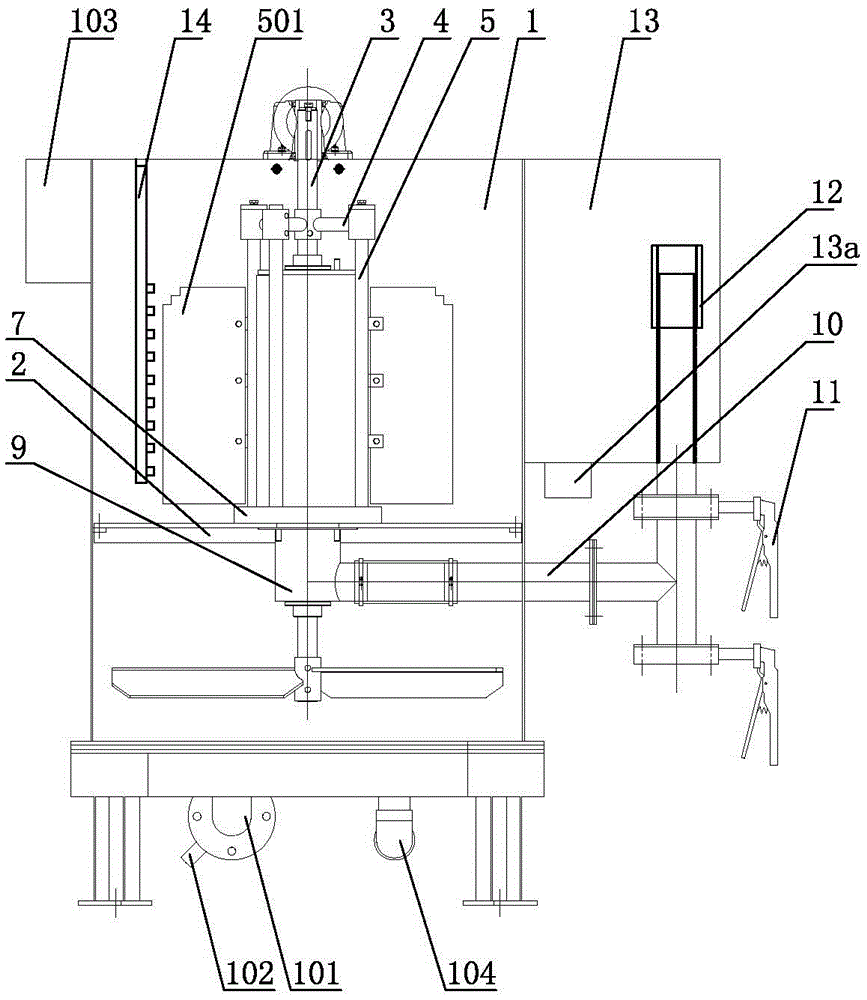

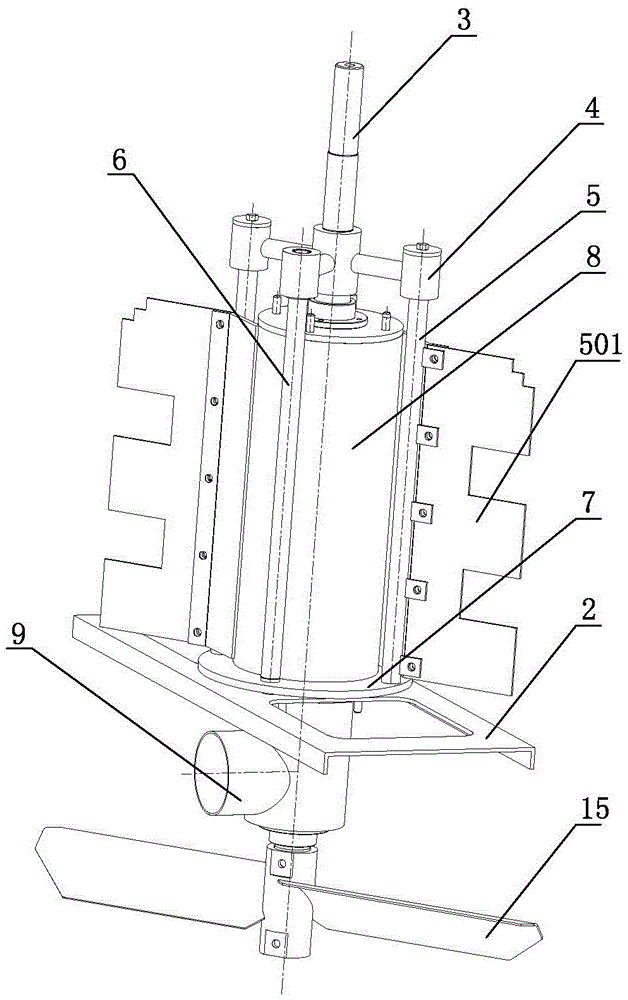

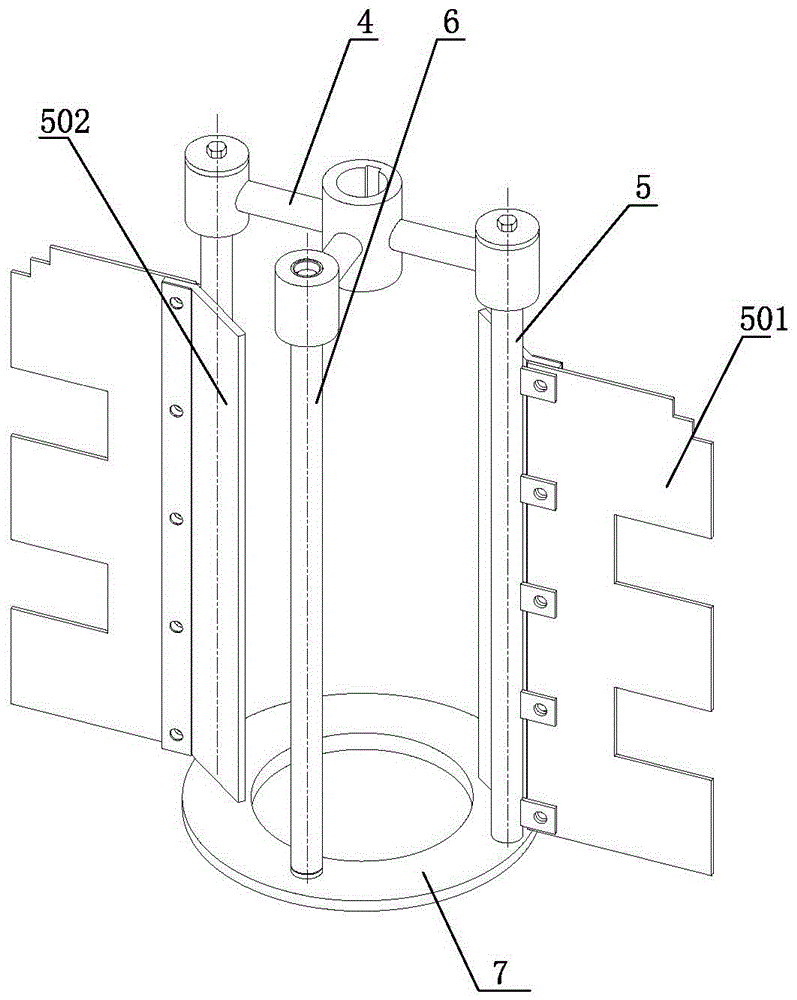

[0030] 3) Stirring and filtering: start the motor, the drive shaft 3 drives the stirring shaft frame 4 to rotate, the stirring paddle 501 stirs the sludge and the medicine, the sludge and the medicine are fully mixed, and the moisture in the sludge is filtered by the filter assembly 8 and then enters the drain pipe 9 , the scraper 502 on the stirring shaft 5 rotates and scrapes off the residual sludge on the filter assembly 8, the filtrate in the drain pipe 9 enters the outer drainage tank 13 through the tee pipe 10, and is discharged from the water outlet 13a, and...

Embodiment 2

[0034] 1) Preparation of medicament: mix polyacrylamide with water to prepare a medicament with a mass fraction of 1‰;

[0035] 2) Feeding and dosing: the sludge to be treated is passed into the mixing flocculation tank 1 through the feeding port 101, and the above-mentioned chemical is passed into the mixing flocculation tank 1 through the dosing port 102, and the sludge and the chemical are mixed with each other;

[0036] 3) Stirring and filtering: start the motor, the drive shaft 3 drives the stirring shaft frame 4 to rotate, the stirring paddle 501 stirs the sludge and the medicine, the sludge and the medicine are fully mixed, and the moisture in the sludge is filtered by the filter assembly 8 and then enters the drain pipe 9 , the scraper 502 on the stirring shaft 5 rotates and scrapes off the residual sludge on the filter assembly 8, the filtrate in the drain pipe 9 enters the outer drainage tank 13 through the tee pipe 10, and is discharged from the water outlet 13a, and...

Embodiment 3

[0040] 1) Preparation of medicament: mix polyacrylamide with water to prepare a medicament with a mass fraction of 1‰;

[0041] 2) Feeding and dosing: the sludge to be treated is passed into the mixing flocculation tank 1 through the feeding port 101, and the above-mentioned chemical is passed into the mixing flocculation tank 1 through the dosing port 102, and the sludge and the chemical are mixed with each other;

[0042] 3) Stirring and filtering: start the motor, the drive shaft 3 drives the stirring shaft frame 4 to rotate, the stirring paddle 501 stirs the sludge and the medicine, the sludge and the medicine are fully mixed, and the moisture in the sludge is filtered by the filter assembly 8 and then enters the drain pipe 9 , the scraper 502 on the stirring shaft 5 rotates and scrapes off the residual sludge on the filter assembly 8, the filtrate in the drain pipe 9 enters the outer drainage tank 13 through the tee pipe 10, and is discharged from the water outlet 13a, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com