Four-edge sealing packer

A packaging machine and four-side sealing technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low production efficiency, inaccurate feeding, inconvenient feeding, etc., to achieve reliable travel, accurate and error-free feeding, Easy and convenient effects to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

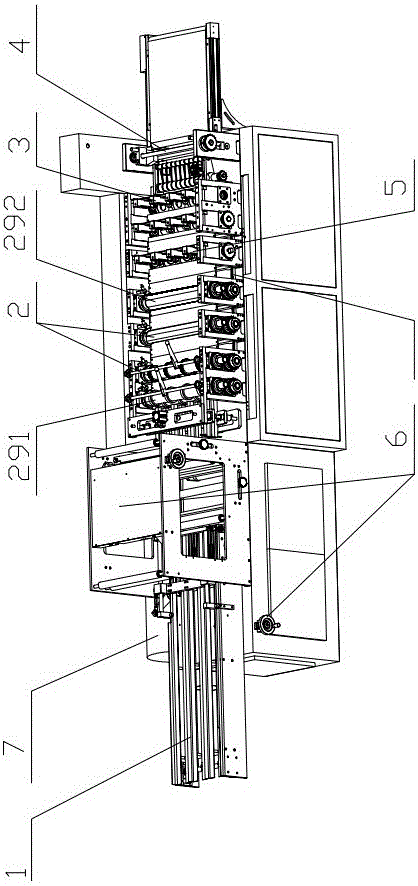

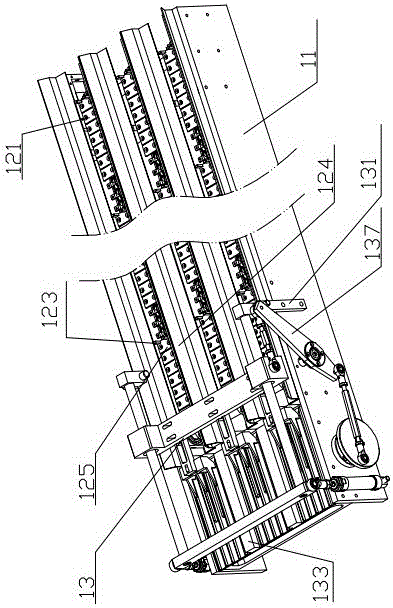

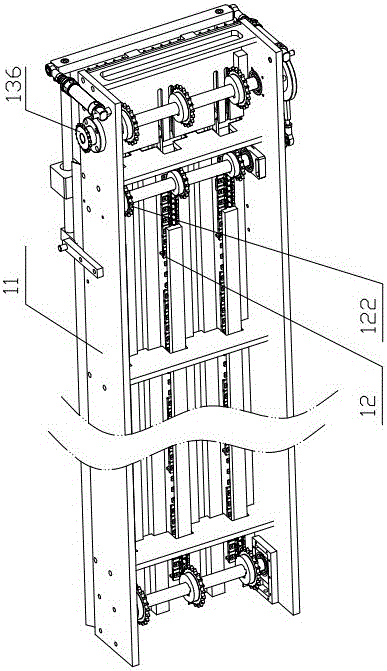

[0035] Depend on figure 1 combine Figure 2-18 As shown, a four-side sealing packaging machine includes a folding device 6 for packaging film feeding, a feeding device 1 for material feeding, a heat-sealing device 2 for four-side heat sealing, and a The slitting device 3 and the cross-cutting device 4 for transverse shearing, the folding device 6 are connected with the packaging film feeding mechanism 7, which can belong to the four-side sealing packaging machine, and can of course be provided separately. The feeding device 1, the heat sealing device 2, the slitting device 3 and the cross cutting device 4 are sequentially connected, the tearing device 5 is arranged between the heat sealing device 2 and the slitting device 3, and the cross cutting device Existing devices are adopted, and details are not repeated here. The structure of the tearing device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com