Round nut tightening device

A round nut and sun gear technology, applied in the field of machinery, can solve the problems of insufficient universality of torque wrenches, lack of tightening devices, etc., and achieve the effect of compact structure, good universality and reduced radial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following further describes the present invention with reference to the drawings and specific embodiments to help understand the content of the present invention.

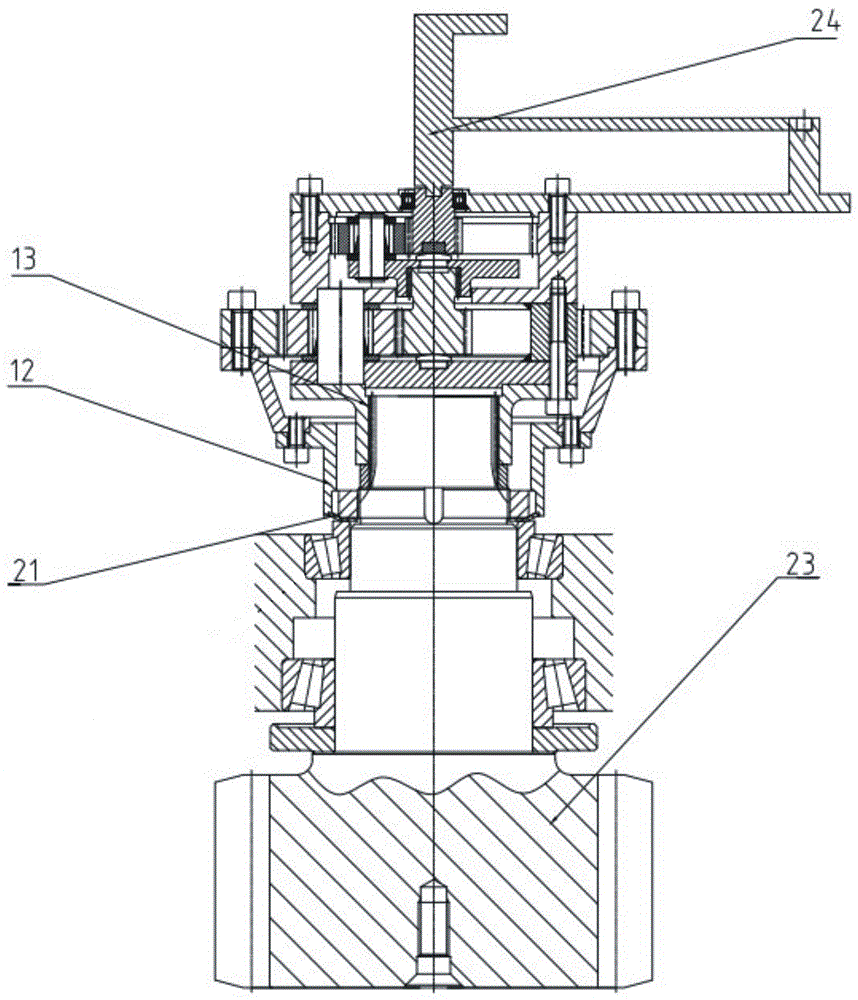

[0039] Such as figure 1 with figure 2 As shown, the present invention provides a round nut tightening device, including an input mechanism and a tightening mechanism; the tightening mechanism includes a second planetary gear, a key chuck 13 and a claw chuck 12; the second planetary gear includes a second The sun gear 5, the inner ring gear 7 and the second planet gear 6; the second sun gear 5 and the inner gear ring 7 mesh with the second planet gear 6; the key chuck 13 and the second planet The axle of the wheel 6 is relatively fixed; the ring gear 7 and the claw chuck 12 are relatively fixed; the output of the input mechanism is drivingly connected to the second sun gear 5; the key chuck 13, the claw The chuck 12 and the second sun gear 5 are both coaxially arranged and can rotate relative to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com