Earpiece polishing machine

A technology for spectacle temples and polishing machines, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., and can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

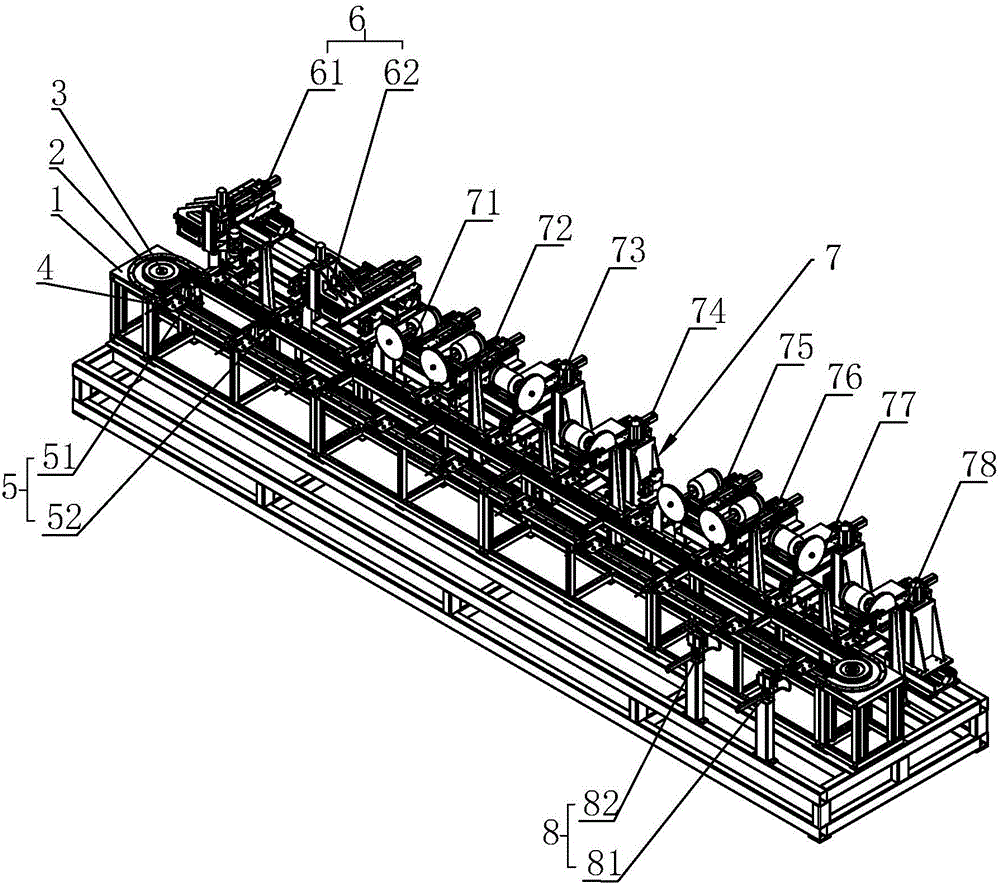

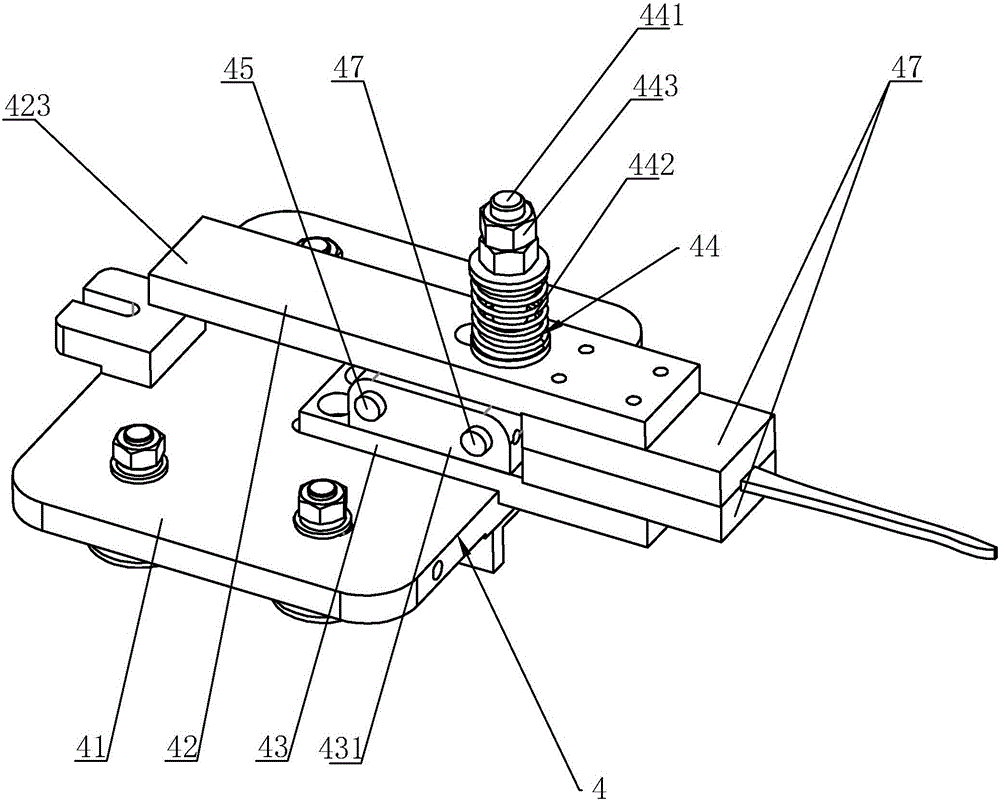

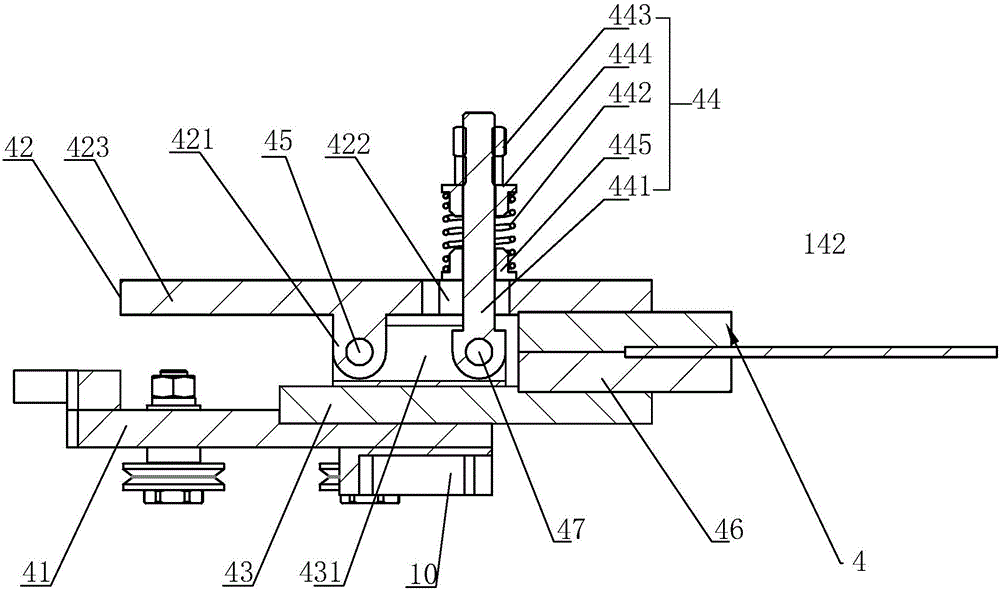

[0025] Refer to attached Figure 1 to Figure 8 A spectacle temple polishing machine of the present invention is described in further detail.

[0026] A spectacle temple polishing machine, comprising a frame 1, a conveyor belt 2 arranged on the frame 1, and a conveying driver 3 for driving the conveyor belt, the conveying driver 3 is a motor, and the conveyor belt 2 is a closed endless belt, which can realize repeated feeding and For unloading, the conveyor belt 2 is provided with clamping devices 4 for clamping eyeglass pins; wherein the number of clamping devices 4 is multiple, and the intervals are evenly distributed on the conveyor belt 2 to improve production efficiency.

[0027] The frame 1 is also provided with an opening mechanism 5 for opening the clamping device 4, a milling mechanism 6 for milling the temples, a polishing mechanism 7 for the temples, and a cleaning mechanism for cleaning the temples after milling and polishing. Cleaning mechanism 8 ; the opening mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com