Preparation method of magnesium alloy microtubule and special-purpose die

A magnesium alloy and composite mold technology, applied in the direction of metal extrusion molds, etc., can solve the problems of low forming rate, difficult forming, and failure to achieve absolute isothermal, etc., achieve high forming rate, improve mechanical properties, improve mechanical properties and corrosion resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention is a kind of preparation method of magnesium alloy micropipe and special mold, and the steps of its method are:

[0022] (1) Preparation of as-cast magnesium alloy blank:

[0023] In the magnesium alloy, the content of Y is 3.6-4.2% by mass percentage; the content of Nd is 2.1-2.5%; the content of La (Ce) is 0.2-0.8% (65%La+35Ce); the content of Zr The content is 0.2-0.8%, and the rest is Mg;

[0024] Melting and casting in a vacuum induction furnace with high-purity argon, the pouring temperature is 780-800 °C;

[0025] The as-cast alloy is subjected to solid solution and homogenization annealing treatment, the solution treatment temperature is 470-510°C, the holding time is 6-10h, and cooled in the air; the homogenization annealing temperature is 460-500°C, and the holding time is 10 ~16h, cooling with the furnace;

[0026] (2) Preparation of ultra-fine grain blank:

[0027] The ultra-fine-grained magnesium alloy microtube billet is prepared ...

Embodiment 1

[0040] Embodiment 1: the preparation method of magnesium alloy microtube, the steps are as follows:

[0041] (1) In terms of mass percentage, in the alloy, the content of Y is 3.6%, the content of Nd is 2.1%, the content of La(Ce) is 0.2%, the content of Zr is 0.2%, and the rest is Mg. Good magnesium alloy raw materials are smelted and cast in a vacuum induction furnace with high-purity argon at a melting temperature of 800°C;

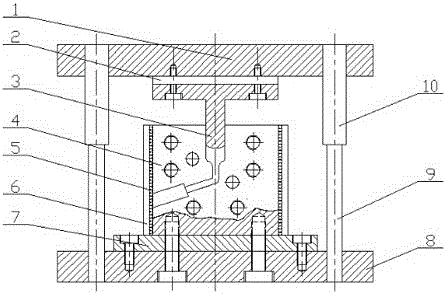

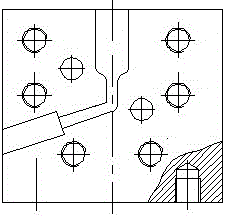

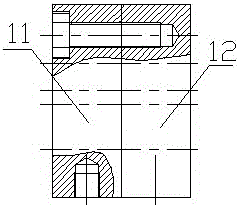

[0042] (2) Then keep it at a temperature of 495°C for 8 hours and cool it in air, keep it at a temperature of 485°C for 12 hours and cool it with the furnace. The cast alloy after heat treatment is processed into a cylindrical rod with a diameter of 30mm, and composite extrusion is performed through a conical die forward extrusion and an equal-diameter angular extrusion composite mold. First, the cylindrical rod is put into the composite mold and heated The heating temperature of the resistance wire is 510°C, and a 10KN press is used to extrude the co...

Embodiment 2

[0048] Embodiment 2: the preparation method of magnesium alloy microtube, the steps are as follows:

[0049] (1) In terms of mass percentage, in the alloy, the content of Y is 4.2%, the content of Nd is 2.5%, the content of La(Ce) is 0.8%, the content of Zr is 0.8%, and the rest is Mg. Good magnesium alloy raw materials are smelted and cast in a vacuum induction furnace with high-purity argon at a melting temperature of 800°C;

[0050] (2) Then keep it at a temperature of 495°C for 8 hours and cool it in air, keep it at a temperature of 485°C for 12 hours and cool it with the furnace. The cast alloy after heat treatment is processed into a cylindrical rod with a diameter of 30mm, and composite extrusion is performed through a conical die forward extrusion and an equal-diameter angular extrusion composite mold. First, the cylindrical rod is put into the composite mold and heated The heating temperature of the resistance wire is 510°C, and a 10KN press is used to extrude the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com