Natural low-sugar red fruit juice and processing technology thereof

A processing technology, red technology, applied in the direction of food ingredients containing natural extracts, the function of food ingredients, and food ingredients as odor improvers, etc., can solve the problems of unseen natural low-sugar fruit juices, etc., and achieve product uniformity, stability, and maintenance Taste, effect of short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

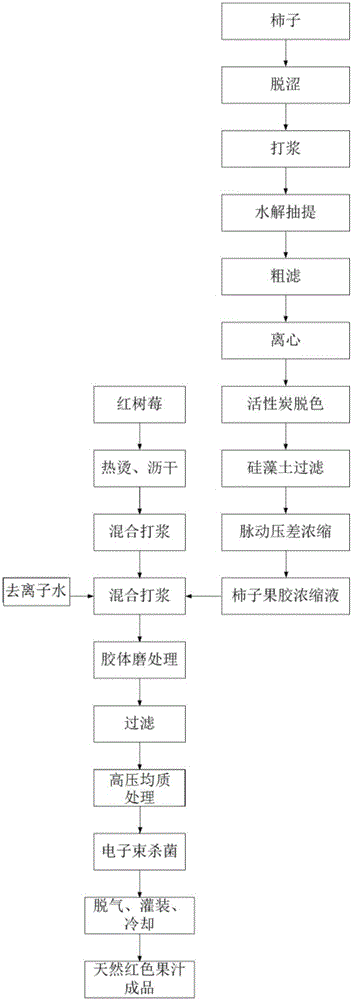

Image

Examples

Embodiment 1

[0059] 1) Select fresh and ripe red raspberries, remove branches, leaves and rotten fruits to obtain 10kg of red raspberry fruits, rinse with clean water, drain the water, blanch at 95°C for 5 seconds, and drain the water;

[0060] 2) Select ripe persimmons, obtain 50kg persimmons, rinse with clear water, and drain the water;

[0061] 3) Put the persimmons in a desiccator with good airtightness, and pass 60% CO into the desiccator 2 Treat for 24 hours, so that the content of soluble tannins is lower than 0.5mg / g;

[0062] 4) Beating to obtain 15L of persimmon pulp, adding 150mL of lemon juice to the crushed persimmon pulp to make the pH of the solution 2 to 2.5;

[0063] 5) Add 135L of softened drinking water, hydrolyze and extract at 95°C for 50 minutes, and after the extract is coarsely filtered, use a disc centrifugal separator to separate solid impurities to obtain primary pectin extract;

[0064] 6) Add 0.3% to 0.5% activated carbon, stir at 50-60°C for 20-30 minutes, d...

Embodiment 2

[0068] 1) After thawing frozen red raspberries at room temperature, rinse with clean water, drain the water, blanch at 90°C for 10 seconds, and drain the water;

[0069] 2) Select ripe persimmons, obtain 50kg persimmons, rinse with clear water, and drain the water;

[0070] 3) Put the persimmons in a desiccator with good airtightness, and pass 50% CO into the desiccator 2 Treat for 24 hours, so that the content of soluble tannins is lower than 0.5mg / g;

[0071] 4) Beating to obtain 15L of persimmon pulp, adding 150mL of lemon juice to the crushed persimmon pulp to make the pH of the solution 2 to 2.5;

[0072] 5) Add 135L of softened drinking water, hydrolyze and extract at 90°C for 60 minutes, and after the extract is coarsely filtered, use a disc centrifugal separator to separate solid impurities to obtain primary pectin extract;

[0073] 6) Add 0.3% to 0.5% activated carbon and stir at 50-60°C for 20-30 minutes to decolorize the pectin to obtain a secondary pectin extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com