Airbag module with a control device

A technology of control devices and airbags, applied in transportation and packaging, pedestrian/passenger safety arrangements, vehicle components, etc., can solve problems that are difficult to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

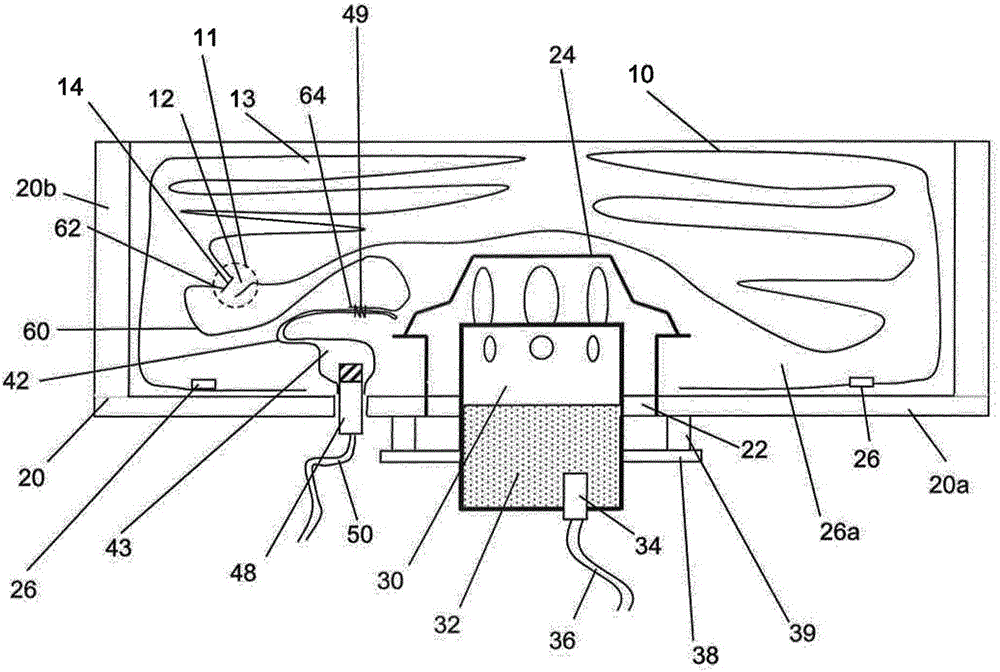

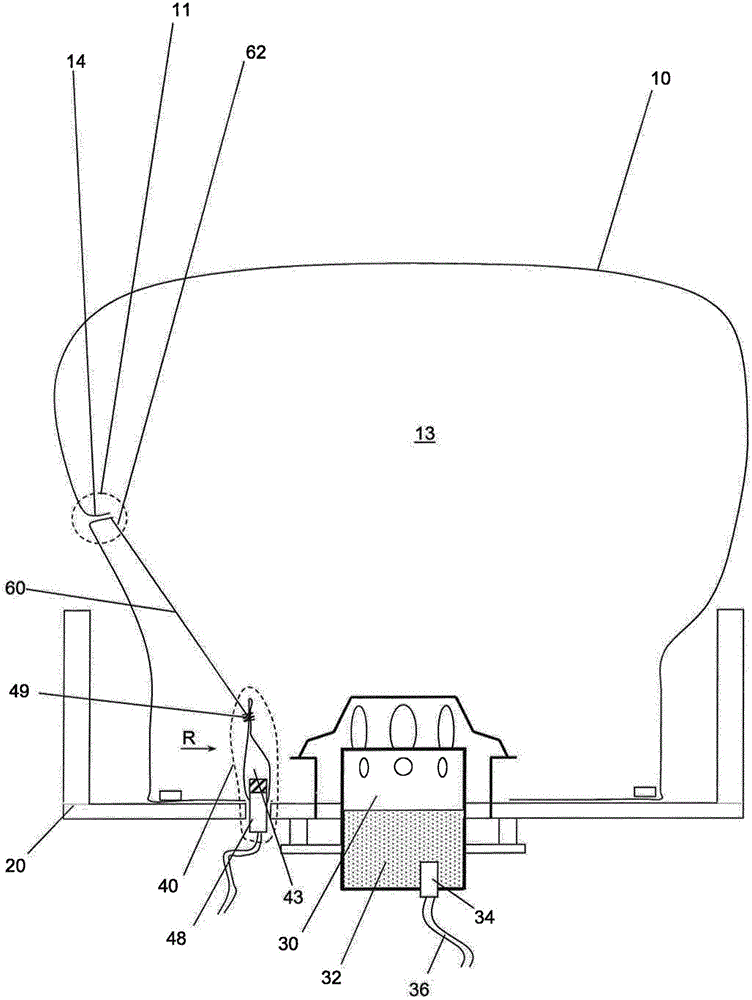

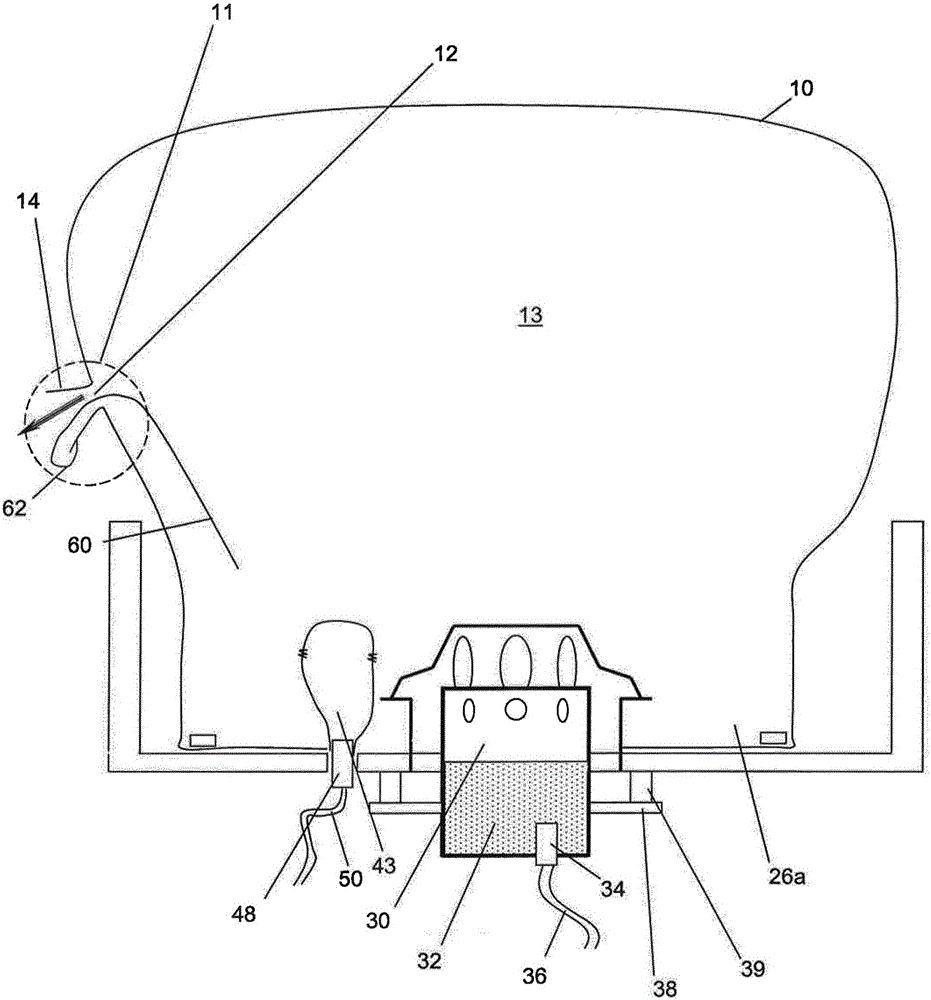

[0026] First, the invention will be explained on the basis of an application example in which the deflation of an airbag is controlled.

[0027] Figures 1 to 3 A front airbag module is shown, that is to say a driver's airbag module for installation in the hub region of the steering wheel. The airbag module is basically constructed in a conventional manner: that is to say, it has a housing 20 with a housing wall 20 b and a housing bottom 20 a, in the initial state, referred to here as the first housing 10 The airbag cover is folded into the housing. The first housing 10 surrounds a first gas chamber 13 . The first casing 10 is held on the housing bottom 20 a by means of a retaining ring 26 . A first inflatable, i.e. a gas generator 30 is used to fill the first gas chamber, which in the illustrated embodiment extends through an opening 22 in the housing bottom 20a into the interior of the housing 20 and from there to In the first gas chamber 13 . The gas generator 30 has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com