Double apron drafting unit for spinning frame

A spinning frame and apron technology, applied in the dual fields of the machine, can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

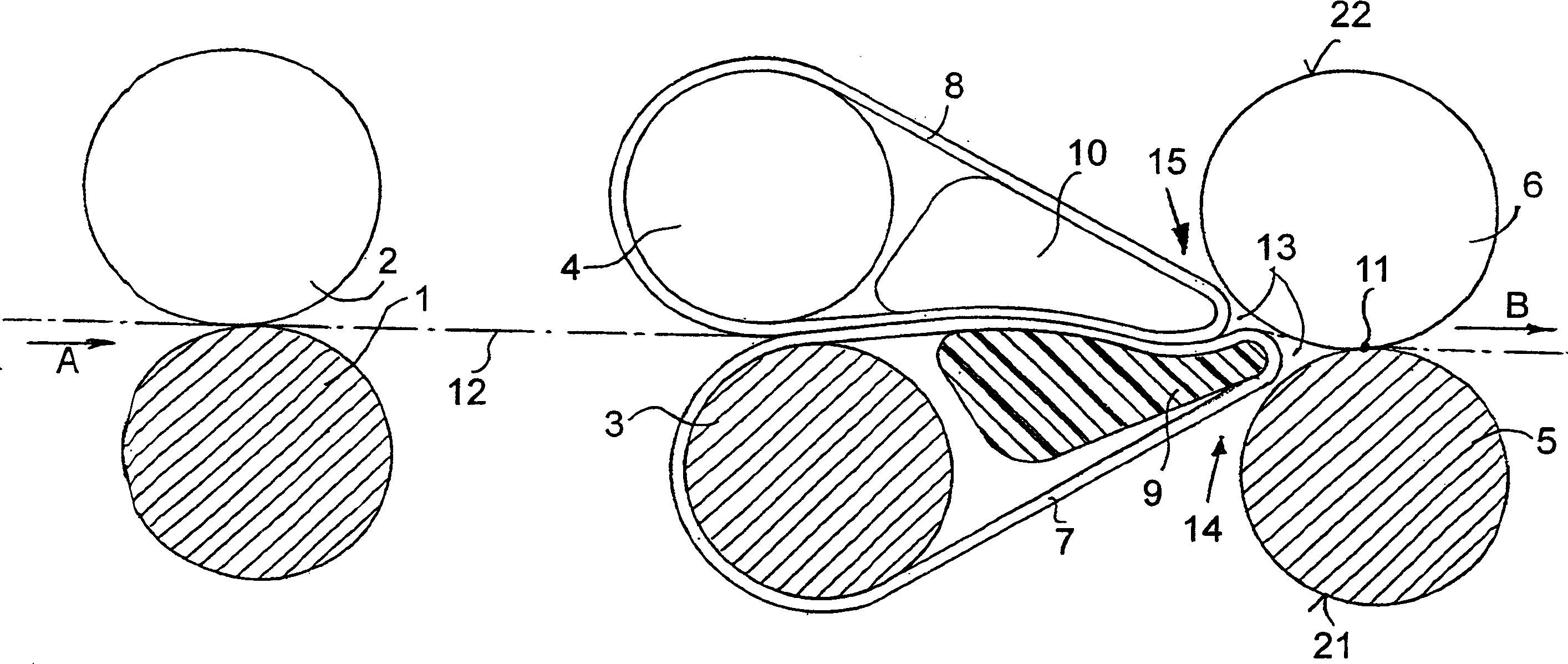

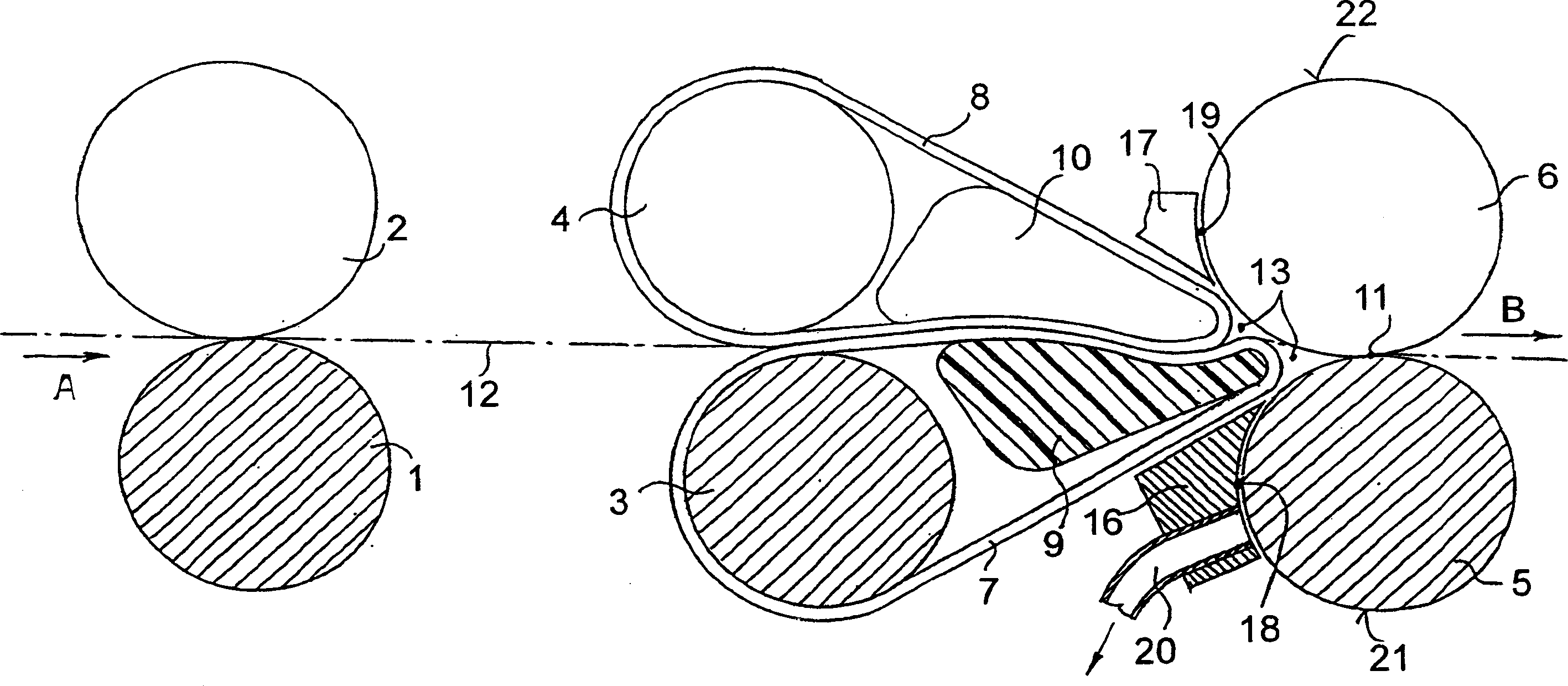

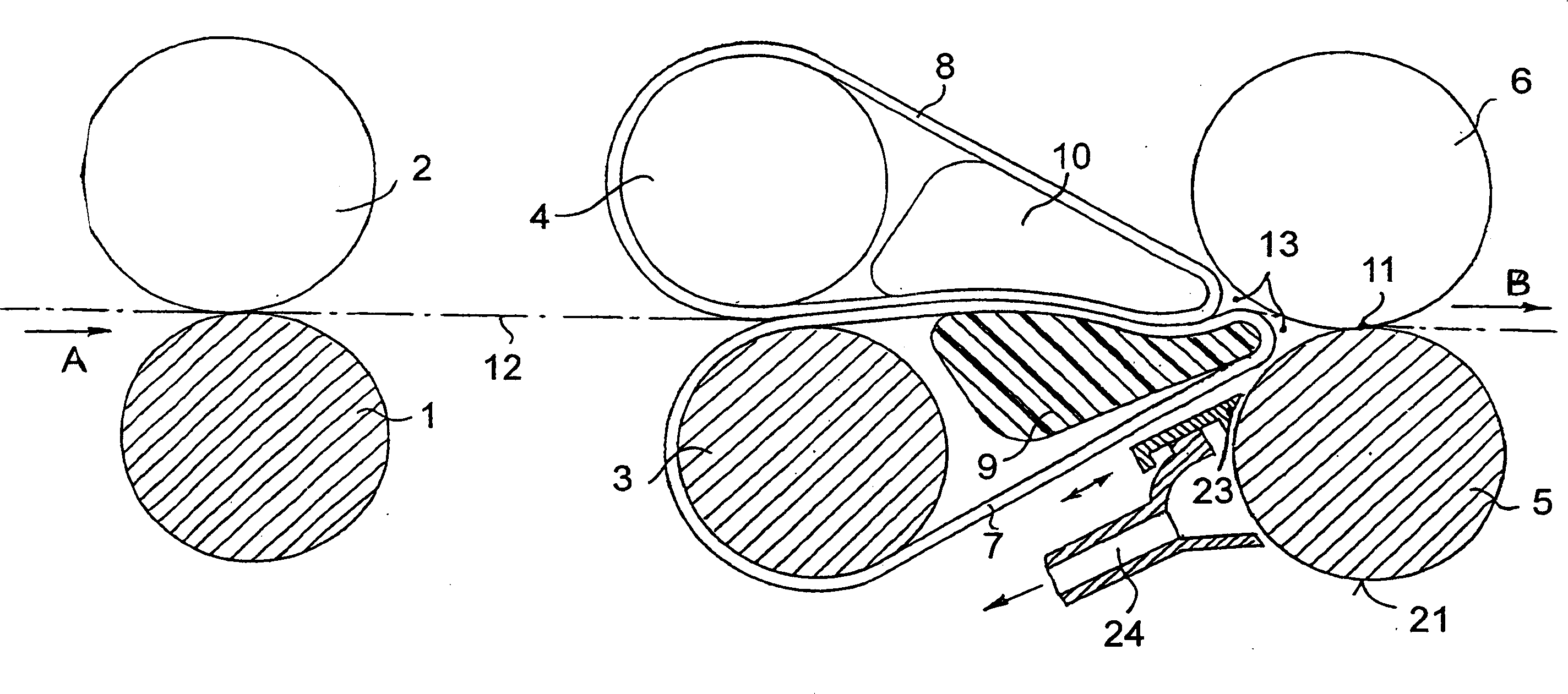

[0025] for spinning machines figure 1 The double apron drafting unit shown uses a three-roller drafting unit and comprises a feed roller 1,2, apron roller pair 3,4 and delivery roller pair 5,6. Rollers 1, 3 and 5 are here driven bottom rollers, rollers 2, 4 and 6 are corresponding pressure rollers on which they are elastically arranged. Apron roller pair 3,4 is surrounded by apron pair 7,8, while apron 7 is the lower apron and apron 8 is the upper apron. Reference numeral 9 designates a guide for the lower apron 7 and reference numeral 10 designates a guide for the upper apron 8 .

[0026] The delivery roller pair 5 , 6 defines a delivery gripping line 11 , at which the drafting of the fiber bundle 12 to be drawn, indicated by a dotted line, ends. The fiber bundle 12 is fed in the feed direction A to the double-apron drafting unit and then in the output direction B downstream of the output gripping line 11 to a twisting device (not shown).

[0027] An advantageous effect on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com